From bulky waste bags or thick plastic shop bags to lightweight ziplock bags or thin top sheet film for pallet protection. Plastic is a multifunctional, lightweight and flexible material, which is why it is so popular as a packaging material. But how is it made, how is it recycled and how can it be replaced with more environmentally friendly alternatives? We answer your questions.

How are plastic bags made?

Traditionally, plastic bags are made from oil, which undergoes a number of heating and printing processes to give the material its final shape. In fact, 6% of the world’s oil is used to make plastic, and 40% of this plastic is made into bags.

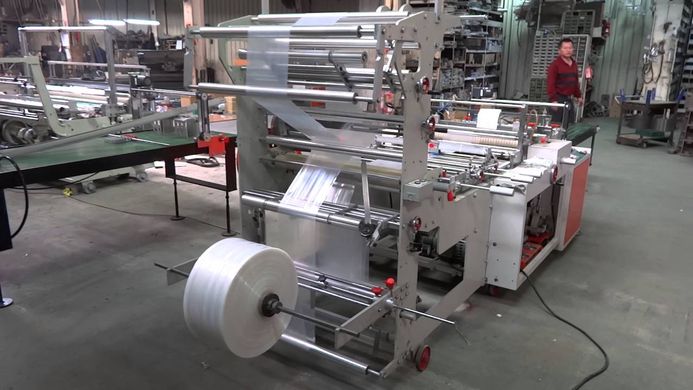

Oil is processed with heat and pressure to create long-chain polyethylene molecules, resulting in lightweight plastic pellets. Different combinations of heat and pressure produce different densities of plastic. Carrier bags, for example, are usually made of High Density Polyethylene (HDPE) and plastic film and thinner bags are made of Low Density Polyethylene (LDPE).

The resulting polyethylene pellets are then reheated and extruded to produce a film – of varying thickness depending on use – which is then cut to the correct size. In a final step, the material is heated again to seal the seams and form a bag.

How can plastic bags be reused?

Feel free to reuse your plastic bags several times – the material is optimal for reuse as it is very strong relative to its weight. Plastic shopping bags and carrier bags can be used many times to carry groceries or other items. Thinner bags can also be reused, for example for storing or protecting small items of various kinds.

In addition to reusing plastic bags as sacks, you can, for example, reuse plastic bags as filling material when sending parcels, or cover outdoor plants during winter to protect them from frost, or protect paintbrushes when they are not in use… The uses are endless and the sky’s the limit. Remember, every time you find a new purpose for a used plastic bag, you reduce that bag’s carbon footprint just a little. And when you can’t reuse more times in private use – make sure you recycle it!

Why is it important to recycle plastic bags?

Because plastic bags are so useful, they are produced in huge volumes for all sorts of purposes. But the indestructible nature of the material means they need to be reused or recycled rather than thrown away. If plastic materials end up in the environment, it takes an incredibly long time for them to decompose. And although it can break down to some extent over hundreds of years, it still remains in the environment in the form of microplastics, which because of their size are particularly tough to remove from the environment.

Do it right from the start – reuse your plastic bags where possible, and sort your plastic waste as plastic material in the recycling.

How are plastic bags recycled in Sweden?

The recycling process for plastic materials differs from country to country. Recently, SVT released the documentary “The recycling scam” which reveals, with an international perspective, that only 1% of all plastic is recycled. The documentary looks at examples where we can see the process being mismanaged on a large scale – we see dozens of pallets of well-sorted plastic items being burnt instead of being used as promised as material for new plastic items. Is this something we need to worry about in Sweden?

This is how the Swedish Plastics Recycling Association and the Swedish Packaging and Newspaper Association (FTI) respond, in a letter published in Dagens Nyheter:

“All plastic packaging left at one of FTI’s 5,000 recycling stations around the country, or collected via property-based collection from 2 million households, goes to Svensk Plaståtervinnings sorting and recycling facility in Motala. Here it is sorted, sort by sort, and then sent for washing and granulation by certified partners in the EU – and regular audits are carried out here.

The letter goes on to describe how the collected plastic is turned into recycled raw material, and that the resulting residual waste is recycled into energy in Sweden and used, for example, to heat homes.

Despite the fact that, according to the letter, Sweden is a world leader in plastic recycling, as much as half of all plastic packaging ends up in household waste. This packaging is therefore not recycled, but is instead incinerated in heating plants. So by sorting your plastic waste, you’re doing your bit for the environment. But how do you make sure you’re sorting correctly?

How do I recycle plastic packaging?

The first step when considering how to recycle a material is to decide if it is recyclable. Consumables such as packaging and fillers are generally recyclable. If you are unsure whether a material or item is recyclable, you can search the FTI sorting guide.

Before recycling, it is important that you separate and sort different types of materials as best you can. Is it not possible to separate the material types? If so, sort for recycling on the basis of the predominant type of material.

If you’re recycling a box you’ve received in the post, make sure you remove the plastic packing tape and any plastic pockets from the box and sort the materials separately (or better still, use paper tape and paper packing slip envelopes – this will make recycling easier for your customers, as the whole package can be sorted as paper). Make sure to fold the cardboard so that it takes up less space in the recycling bin.

Need to recycle padded envelopes with bubble wrap inside? Remember to remove the bubble wrap if possible so that you can sort the layers of material separately. Note that ordinary paper envelopes that you often find in offices are not recyclable, even though they sometimes have plastic windows. They should therefore be sorted as household waste and sent for incineration. This is because envelopes are not part of the producer responsibility for packaging and newspapers, so they are not produced to be recycled.

How can I reduce my company’s carbon footprint related to plastic packaging materials?

As an e-retailer, you are faced with the choice of what type of packaging is best suited to provide protection for your products during transport, to ensure that products arrive in good condition. In addition to providing your products with adequate protection, it is of course also important that your packaging makes as small a carbon footprint as possible, here are three aspects you can use to evaluate your packaging choice:

1. Choose paper packaging materials

Generally speaking, paper materials such as corrugated board and kraft paper are better for the environment than plastic, as they are biodegradable in nature, are recycled to a greater extent and in many cases already consist of recycled material (for example, all cardboard boxes in RAJA’s range consist of at least 70% recycled material). Look at your existing use of plastic – can you replace the packaging material with an alternative made from paper?

Here you can start from the four stages of a packaging process:

- Packing: cardboard boxes, cardboard envelopes, cardboard tubes, paper e-commerce bags, paper carrier bags

- Protect: paper protectors such as kraft paper or tissue paper, paper-filling packaging machines

- Seal: paper tape, sealing strips

- Shipping: transport labels, paper packing envelopes

Read more about this in our guide: how to replace 3 common packaging products with environmentally friendly alternatives

2. Choose recycled plastic packaging materials

There’s a reason plastic is popular – it weighs little while providing flexible, tear-resistant and water-resistant protection. If plastic is the right choice for you, make sure you reduce your carbon footprint by using recycled materials. Here’s a selection of RAJA’s range, which is constantly expanding to include more eco-friendly options:

- Eco-friendly plastic bags – up to 100% recycled plastic. See also our plastic bags with die-cut carrying handles, where most items are made from 100% recycled material (see details in table).

- White e-commerce bags made from 100% recycled plastic

- Eco-friendly stretch film – made from 80% recycled material

- Eco-friendly bubble wrap – made from 80% recycled material

- Eco-friendly packing tape – made from 80% recycled material. PET strapping is a lighter alternative to steel strapping, designed for strapping heavier pallets.

3. Choose packaging materials that require less material input

The more waste you produce, the bigger your carbon footprint – by using innovative packaging solutions you can be more efficient, more economical and more environmentally friendly – all at the same time, by using less material. Here are three packaging solutions that do just that:

- PP tape Airtape – a thinner PP packing tape that emits approximately 30% less CO2 emissions per metre of tape when produced.

- Pre-stretched stretch film – does not need to be tightened before use. It uses 20-30% less material compared to standard hand stretch film, while pre-stretched stretch film is easier to apply.

- Packaging that can be reused in returns: these packs have double self-adhesive cover strips, which means your customers can use the same packaging for any returns. Simpler, and better for the environment.

- Easybox “return”, with smooth quick release

- E-commerce “return” bags

- Return e-commerce bags with handle

Need help reducing the environmental impact of your packaging choices?

RAJA are specialists in packing tape, packaging and wrapping. Please contact us for tips and advice on how your packaging choices affect the environment. The number is 010 – 33 08 200 and we are open weekdays from 07:30-17:00.

Feel free to explore our environmentally friendly range of packaging products online!

Stay in touch with us

- Subscribe to our newsletter for the latest packaging news and access to exclusive promotions

- Follow RAJA Sweden on Linkedin, Facebook and Instagram

- Check out our latest product catalogue – order a free copy or read the interactive catalogue online

Read the next blog post: