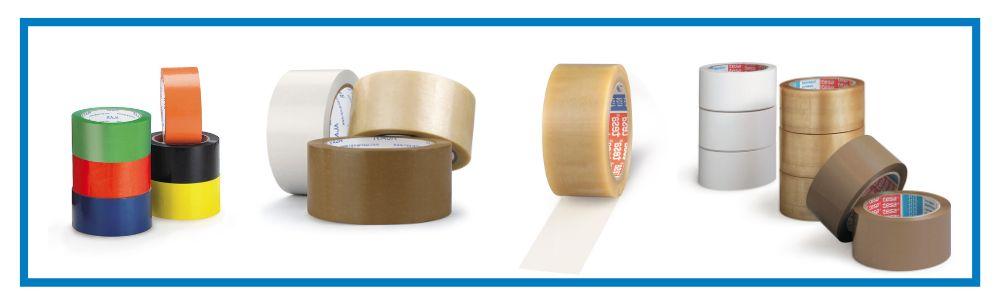

As you may have noticed, there are several different types of adhesive tapes to choose from. Here we will explain the qualities of the different tapes and when it is best to use each tape. Using the right tape, tailored to your needs from the outset, reduces the risk of making the wrong choice and ensures that your packaging is properly sealed and gives your products the right protection during transport.

Elements of a packing tape

To choose the right packing tape, it can be useful to know the different components of a tape. A tape usually consists of two parts – carrier and adhesive. The carrier is the material of the tape itself and the adhesive is the type of glue used. Some tapes, mainly PP tapes, also have a so-called release that sits on the outside of the carrier and allows it to be easily unrolled from the roll without sticking, and a layer of primer that sits between the carrier and the adhesive and ensures that the two sit together as they should.

But here we concentrate on the 2 most important parts, the type of tape (carrier) and adhesive that is right for you.

The most common packing tapes are PP (polypropylene) tape, PVC (polyvinyl chloride) tape and paper tape. PP tape can have three different adhesives: hot melt, acrylic or natural rubber. PVC tape and paper tape are available in different qualities and thicknesses but always use natural rubber as an adhesive.

Which packing tape to choose?

When choosing packing tape, there are several factors to consider: the material of the boxes, the weight of the contents, the number of boxes to be packed, how they will be transported and stored, and how important it is that the tape is environmentally friendly. Answers to these questions will determine which packing tape is best for you: PP, PVC or paper tape.

PP hot melt tape – the most economical choice

PP hot melt tape is suitable for those who do not need to pack many or heavy boxes. The hot melt adhesive makes the tape noisy when used, but it is the most cost-effective option. Easy unrolling.

Silent PP tape

PP tape with acrylate is available in different thicknesses of plastic and adhesive which means it can be used for both light and heavier boxes. PP acrylic tape is quiet when unrolled. Also suitable if the box may be exposed to higher temperatures. Used instead of PVC when environmental requirements are met.

PVC tape – the classic packing tape

PVC tape has a slightly duller surface than PP tape and medium to sluggish unwinding. Best used for heavier boxes. Suitable for all corrugated qualities. Quiet in use. Can be used in damp and cold environments. However, application at room temperature is recommended. Suitable for transport as it can withstand shock loads due to the high breaking strength and low elasticity of the PVC tape (it does not expand and can therefore withstand more movement on, for example, a pallet during transport).

Psst. Want to colour code while taping? Then choosecoloured PVC packing tape. Want to use packing tape to communicate fragile contents? Then choose PVC warning tape with standard printing such as “Aktas”.

Paper tape and sealing strips best for the environment

Paper packing tape is best for the environment and does not need to be removed from the box when it is recycled. RAJA’s paper tape consists of unbleached kraft paper with the adhesive natural rubber. Medium unwind. Paper tape can be torn off by hand and has low elongation. Available with different thickness of paper and for really heavy packages you can choose reinforced paper tape.

Sealing tape is a paper packing tape that has an odourless adhesive that is activated with water. It cannot be removed from the carton without being seen. If you choose this tape, you should also buy a manual or electronic tape dispenser with a water reservoir, which moistens and cuts the tape strips. Watch the video below to see how.

Read also: product guide – masking tape, paper tape and sealing strips

Fibreglass tape perfect for export

Fibreglass tape is a PP packing tape reinforced with longitudinal glass fibre threads. The adhesive is hot melt. This is the tape for those who pack really heavy products. The tape can be used outdoors and is perfect for export deliveries.

Choose tape with natural fibre adhesive for recycled boxes

Boxes come in many different types and sizes. Nowadays, the corrugated cardboard from which the boxes are made is often made of so-called recycled fibre/testliner, i.e. recycled material. Currently, it is said that paper fibres can be recycled up to seven times before the fibres become too short for use, but new research shows that it may be possible to recycle, with high quality, up to 25 times!

There are also boxes that have recycled fibres on the inside of the box and “new” fibres/ kraftliner, on the outside. New fibres then come from virgin pulp. This combination of different papers usually makes for a slightly stronger box. You can also get boxes made entirely with kraftliner/new fibres. If you are unsure about the quality of your boxes, you can always ask your supplier.

For boxes with recycled fibre, we recommend using tape with natural rubber as the adhesive. It adheres better to the substrate. The most common tapes are PVC or paper tape. PP hot melt works on smaller boxes with low weight.

If the boxes have new fibre, you can use any type of tape/adhesive, then it depends more on the size, and weight of the contents, which one to choose.

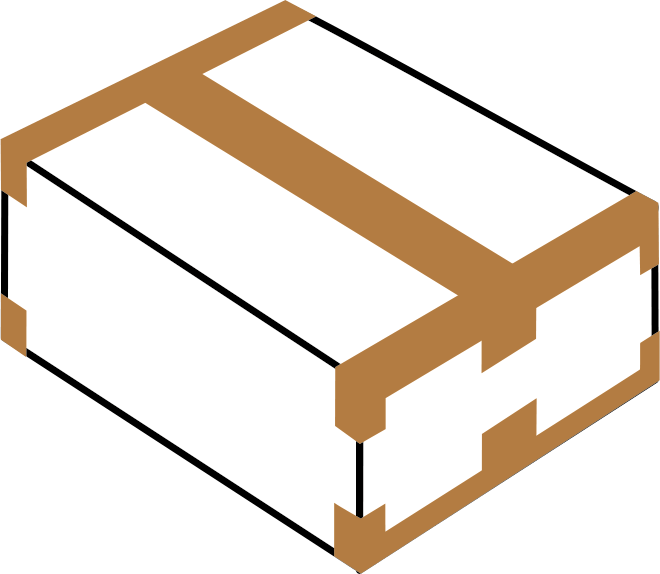

What is the best way to tape a box?

To tape a box in the best way, you should choose a U-shaped seal for boxes up to 20 kg with a short or single transport distance. For boxes up to 40 kg, a combined U- or L-shaped closure is recommended. An H-shaped closure is suitable for large and heavy boxes over 40 kg that will be stored for a long time or transported over a long distance.

| Closure | Used for | Package weight |

Number of tape lengths

|

|

|

U-shaped closure, 2 lengths of tape

|

|

Lightweight packages with short transport distance | Up to 20 kg | 2 pieces |

|

Combined U- or L-shaped closure

|

|

Heavier packages with short transport distance or long storage time | Up to 40 kg | 6 pcs |

|

H-shaped closure

|

|

Heavy and large boxes with long transport distance and long storage time | More than 40 kg | 6 pieces |

With the right tape, you don’t have to “over tape” the box, which is a common practice if you’re unsure of how the tape will behave. By using the right sealing method depending on the contents of the package and the transport distance, you prevent unnecessary waste of packing tape while keeping the package secure.

PS. Want to pack even faster and smoother? Take a look at our Easybox with quick-release foot and self-adhesive cover strip.

How should packing tape be stored?

Packing tape should be stored horizontally, at a constant temperature between 12-23 degrees and in the dark. Store in the packaging the tape came in to protect it from dust. Make sure to use the oldest tape first as tape has a limited shelf life. If the tape gets too hot or cold, leave it at room temperature for 24 hours before using it.

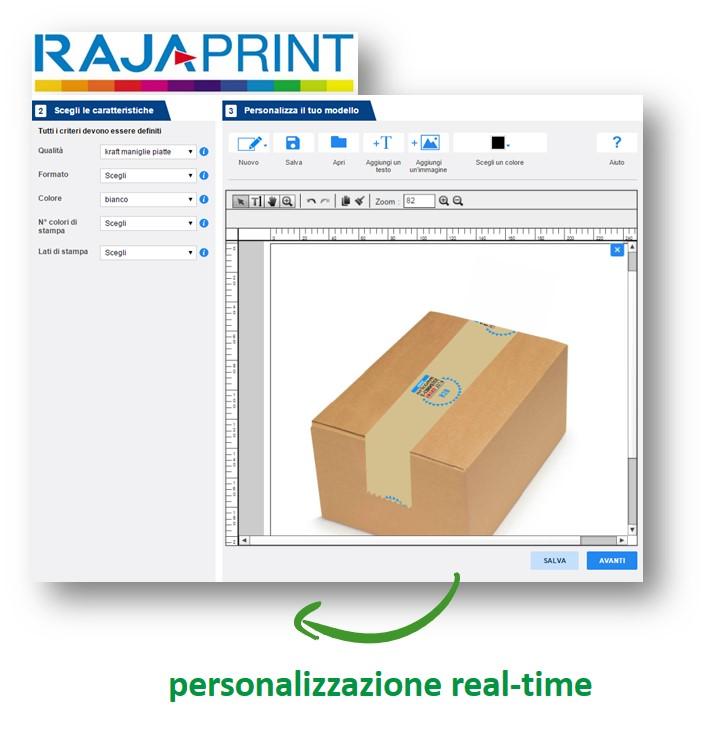

How do you design your own packing tape?

With the Rajaprint tool, you can design and order your own logo packing tape online. Delivery time is 5-6 weeks, but can vary. If you buy larger quantities, you will get a better price. We will help you step by step through the whole process. Keep a good head start to avoid delays.

Packing tape with your own print is one of the most common ways to market/brand your company today. By labelling your boxes or e-commerce bags with the tape, you secure your packaging while strengthening your brand and acting as advertising. In the unlikely event that your shipment goes astray, it will also be easier to identify and find.

Still the most common packing tape is printed on a plastic tape, but paper tape with its eco-friendly appearance has become big lately as an alternative. Paper tape is available in both brown and white (creamy white) but it is the brown version that is most popular. Here you have to be a little careful about the colours of the print as you cannot expect exactly the same results as with plastic tape. But a solid black print on brown paper tape, that’s pretty! See here a couple of examples of tape that our customers Badass Ceramics and Tyanachu have done with us.

Glossary:

| Testliner | Paper made from recycled paper that meets certain strength requirements according to tests. Testliner, which is intended to form the surface layer of corrugated board, is an alternative to kraftliner, which is made from pure sulphate pulp. |

| Kraftliner | A form of paper that is machine-glazed and contains at least 80 % virgin sulphate pulp. Kraftliner is used for the surface layer of corrugated board. (If it is made from recycled corrugated board, it is called testliner) |

| Paper tape | Tape made from unbleached kraft paper from renewable resources and recyclable. Can be recycled together with the cardboard. Adhesive natural rubber |

| PP tape | Tape made from Polypropylene. A plastic material also used in the manufacture of many household products such as bowls, packaging etc. Traditionally considered a more environmentally friendly plastic as fewer chemical additives are used in its manufacture. Available with different adhesives. Recyclable as plastic. |

| PVC tape | Tape made from polyvinyl chloride. The material PVC is one of the most controlled and regulated substances as it was previously considered a “more dangerous” type of plastic. Nowadays, manufacturing is highly regulated, for example through the sustainable use of additives and not least through the European manufacturing industry’s commitment; VinylPlus 2030, their next 10-year commitment to sustainable development. Adhesive natural rubber Recycled as plastic. |