This post was last updated on 8 June 2022.

Stretch film is so much more than just plastic film. It’s an essential element on every layer! But why is it so? It’s simply the perfect solution for securing your pallets, ensuring goods stay in place throughout transit.

Stretch film: important on every layer

Here at RAJA, we can’t do anything without stretch film. A pallet really isn’t complete without some good, even layers of it. In addition to keeping our (and your future) products in place, it also protects against dust, dirt and moisture.

It’s important that the film is applied correctly and that you use just enough to cover your needs. If you use too much stretch film, you’ll need more packaging material, which will increase your costs. On the other hand, if you use too little, your stretch film can tear and damage your goods. Read on to learn how to apply stretch film correctly.

How to choose the right stretch film

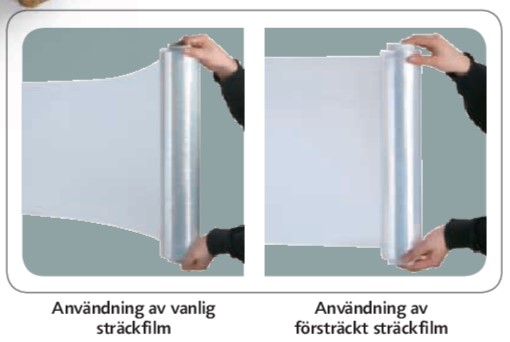

To choose the right stretch film, you need to consider the weight and shape of your pallet. Both hand stretch film and pre-stretched hand stretch film can be used for homogeneous pallets or for pallets with a slightly more irregular shape, but there are important differences.

Hand stretch film is recommended for most palletizing needs. It is a solid, elastic film that easily forms around the goods and secures the load during transport. The fastener is on one side only, and the film also has a quiet unwinding action. Tip: choose environmentally friendly hand stretch film made from recycled plastic or paper.

Pre-stretched hand stretch film is mainly recommended for evenly loaded pallets. The film is inelastic and lightweight and retains its shape after palletising. The fact that it is pre-stretched means that it is very easy to apply and that you save resources compared to non-pre-stretched stretch film. Pre-stretched stretch film means you produce half as much waste as regular stretch film.

What thickness of stretch film should you choose?

The weight of the pallet is a decisive factor when choosing stretch film. The heavier your load, the thicker the stretch film should be. The thickness of plastic film is expressed in micrometres (1/1000 mm), also called my.

| Pallet weight | Film thickness |

| ≤ 500 kg | ≤ 17 my |

| ≤ 700 kg | Between 20 and 23 my |

| ≥ 800 kg | Between 23 and 30 my |

Reduce your carbon footprint with paper stretch film

Is the environment important to you and your business? Then choose paper stretch film, a new addition to RAJA’s 2022 range. This stretch film is made from 100% recyclable PEFC certified kraft paper, an excellent alternative to plastic stretch film. Curious to see what the product looks like? Watch the demo video on RAJA’s youtube channel: https://youtu.be/9SZtAG73vb0

Mini stretch film for smaller packages

The standard size for stretch film rolls is 45 – 50 centimetres wide, but did you know that we also have so-called mini stretch film in our range? These rolls are as small as 10 – 12 cm wide, perfect for those who need to wrap smaller and lighter packages, or perhaps bundle up long products such as pipes. Stretch film is used in conjunction with stretch film dispensers.

Transparent or coloured stretch film?

The most common choice is transparent stretch film, but did you know that you can also use your stretch film to provide privacy or to organize through color coding? RAJA’s black stretch film is opaque and provides really good privacy, this ensures that the contents of your pallet will be condential. If your products are not visible, the risk of theft is reduced. Our coloured stretch film is also available in blue or white – this ensures that your pallets are recognisable, and the colours can be used to structure your warehouse.

Manual or automatic wrapping with stretch film?

There are two ways to apply stretch film: either manually with a hand stretch film dispenser or mechanically with a stretch film machine (note that you will need machine stretch film if you use a machine). If you are filming more than 15 pallets per day, we recommend that you choose one of our wrapping machines.

How to apply stretch film manually?

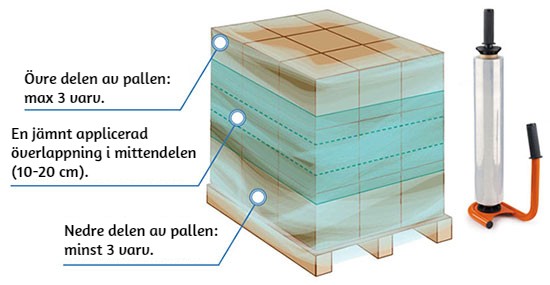

To apply the stretch film to your pallet: mount the roll on the dispenser, apply the sticky side of the stretch film to the load and roll it around the pallet. For the best effect, avoiding over-application of material while using enough to provide adequate protection: apply three layers of stretch film to the top and bottom of the pallet, with an evenly applied overlap in the middle section of about 10-20 centimetres.

How to choose the right stretch film machine?

If you film more than 15 pallets per day, a stretch film machine is recommended. RAJA has stretch film machines in several versions so you can find one that meets your needs. Stretch film machines with mechanical brakes are great for irregular and fragile pallets, and can handle up to 25 pallets in a day. If you have large, irregularly shaped pallets in confined spaces, choose a stretch wrapper with motorised pre-stretch, which can film up to 50 pallets a day. Our most powerful stretch film machine also has a digital control panel and can film as many as 70 pallets in a day.

Need help choosing the right stretch film?

RAJA are experts in everything packaging – from cartons and packing tape to stretch film and packaging machines. Please contact us for tips and advice on which stretch film to choose, or perhaps which stretch film machine is best suited to your needs. The number is 010 – 33 08 200 and we are open weekdays 08:00-17:00.

Stay in touch with us

- Subscribe to our newsletter for the latest packaging news and access to exclusive promotions

- Follow RAJA Sweden on Linkedin, Facebook and Instagram

- Check out our latest product catalogue – order a free copy or read the interactive catalogue online