what temperature and humidity conditions are my goods being shipped in, have they arrived in optimal conditions for consumption, where did this package pass through before it reached its destination? Answering all these questions – and more – will be possible thanks to the smart packagingsmart packaging, a packaging technology designed to keep the product in optimal condition throughout the supply chain, from the time it leaves the manufacturer’s premises until it is consumed or used by the end customer.

Smart packaging is the future of packaging… but at the same time, it is already a very solid present. The data says so. According to the Smart Packaging Market Research Report – Forecast to 2023market Research Future, developed by Market Research Future, smart packaging is a $46 billion market worldwide, with an expected compound annual growth rate of 5.16% for the period 2017-2023.

Smart packaging, what is it?

Smart packagingis a packaging technology that combines the best of two different types of packaging:

- Smartpackaging, which is able to monitor the changes that the products inside the package undergo, both in their condition and in their external storage conditions.

- And activepackaging, which reacts by taking measures to ensure product protection in the face of these changes.

Therefore, smart packaging revolutionises the paradigm of traditional packaging, offering both the producer and the consumer a series of additional services that go far beyond those provided by a simple receptacle that enables the transfer and storage of the goods.

Intelligent packaging + Active packaging = Smart packaging

Smart packagingcombines the functionalities of two types of packaging:

1.intelligent packaging, or smart packaging

Intelligent packaging makes use of sensors and devices that monitor the status and condition of the product and its environment in real time. This makes it possible to measure:

- TTI, or temperature-time indicators, which tell you what temperatures a package has been exposed to and for how long.

- Humidity level.

- Level of degradation, which helps to assess whether a food or any other product for human consumption is still fit for marketing and consumption.

- Traceability:Facilitated by RFID tags, which are not only able to monitor the location of the product at all times, but also to store information on where it has passed through to establish traceability.

2.active packaging

Active packagingis prepared to combat threats along the supply chain by correcting conditions that jeopardise the preservation of the goods.

how does active packaging work? Normally, it emits a substance or absorbs a harmful agent present in the environment (water, oxygen, etc.) when it detects changes in lighting, pressure, temperature, humidity, etc. The aim is to keep the product in the best possible condition for a longer period of time.

which sectors will benefit most from smart packaging?

Smart packagingoffers advantages for the entire logistics ecosystem, but especially for two sectors: food and pharmaceuticals.

Smart packaging in food

The possibilities of smart packaging in food are exciting. One of the most innovative techniques is MAP (Modified Atmosphere Packaging), which is based on extracting the air inside packages and replacing it with a mixture of gases that have a protective effect on food, keeping its nutritional and organoleptic properties intact for longer.

Smart packaging in pharma

Smart packagingin the pharmaceutical sector helps both to guarantee the safety and efficacy of medicines and to encourage patient compliance with prescriptions. Using NFC or Bluetooth technologies, medicine packaging can interact with mobile phones or tablets to show the user how to apply a certain treatment or alert them, via app notifications, that it is time for the next dose.

Although it still faces some economic, legal and environmental challenges, smart packaging is already emerging as the future of packaging.

Current smart packaging solutions

At Rajapack we can help you to implement it in your company with products that detect if goods have been handled incorrectly along the supply chain. With them, you will be able to take better care of the quality and safety of your shipments. Join smart packaging!

COLD ColdMark© falling temperature indicator

it is an indicator that is always active (it does not need to be activated), when it has been exposed to a temperature lower than the indicated temperature for 30 minutes, the window turns purple

Rising temperature indicator WARM WarmMark©

It is a high temperature indicator, activated by pulling the tab and the windows are coloured depending on the time exposed to a higher temperature than the optimum

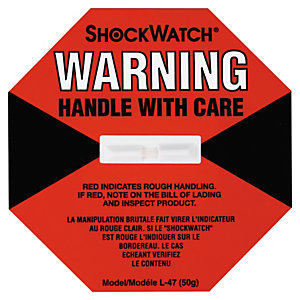

ShockWatch© Impact Indicator

this indicator is ideal for delicate products, if your product receives an impact, the indicator will mark the centre tube of the label with a red tint

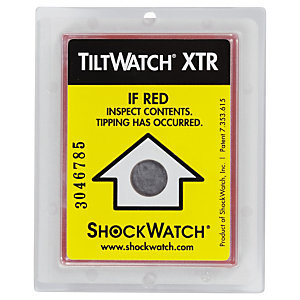

TiltWatch XTR© Rollover Indicator

If your goods are turned over by more than 90°, the indicator will change from black to red and has a serial number to help you ensure traceability of the goods

So, are your goods labelled correctly?