The constant effort to improve the picking space is a common feature among all logistics experts. A good packing station is a key point for efficient, cost-effective and fast outbound logistics. In this post you will find out how to optimise a packing station in 3 steps.

A professional packing station in 3 steps

- Organise the flow around your packing station: Some tips and tricks.

- The essential elements of the packing station: Selecting the essential tools and making them easily available

- Ergonomic packing station rules: To improve the comfort, and therefore the efficiency, of the prepper.

1.

Organise the flow of goods in and out of the warehouse

Order picking areas in a warehouse should be located somewhere in between the incoming and outgoing flows of goods. And remember that it is essential that the different areas of the warehouse are delimited to avoid accidents and facilitate transit

- Colour-coded marking on the floor will help to demarcate the different areas of the warehouse. You can use masking tape.

- It will be very useful for people who are not familiar with these areas, such as suppliers or temporary workers, to be informed of the coding at the entrance to the picking areas as well as in the break rooms.

- Take the goods to the packing station. Once the products have been picked, they are stored in an area close to the order picker. To transport the goods, use transport trolleys or roll containers

Tip: If you have several types of products to pack, specialise your packing stations!For example, organise several types of stations according to the nature of the product to be packed: standard, fragile, large format… This method allows you to have only your specific tools and packaging on each station, thus increasing speed and efficiency.

Tip: If you have several types of products to pack, specialise your packing stations!For example, organise several types of stations according to the nature of the product to be packed: standard, fragile, large format… This method allows you to have only your specific tools and packaging on each station, thus increasing speed and efficiency.

2. Organise your packing station

Select the tools and accessories needed on a packing station

Determine the location of your tools/accessories according to their frequency of use

- The tools and materials that are always used must be close to the order picker: the packaging (boxes, cases, envelopes, etc.), the tape dispenser, the label printer, the waste, etc. and all the packaging and filling elements that are used on a regular basis.

- Tools and materials that are often used should be close to the preparer: protection for fragile products, adhesive tape refill…

- Occasional equipment should be kept in the work area to be used if necessary but not in the way during packing: very specific packaging formats, cutter…

Organise your workspace

A place for everything and everything in its place.it is very important that all the material to be used by the order picker is correctly organised.Rajapack can help you to design the packing station 100% customised and adapted to your needs. A packing station made to measure for you!

3.

Ergonomics of the packing station

You already know where to place the packing station in the warehouse (step 1). Now you have to build your packing station so that the working conditions are optimal (speed and efficiency combined with comfort for the order picker). The packing station is composed of

- A flat work surface (the work table).

- Shelves with or without dividers to store different packaging and accessories.

- Adjustable bars to place the filling rolls (cardboard or bubble).

- A space for rubbish.

the ergonomic recommendations of the French National Institute for Health and Safety at Work (INRS)

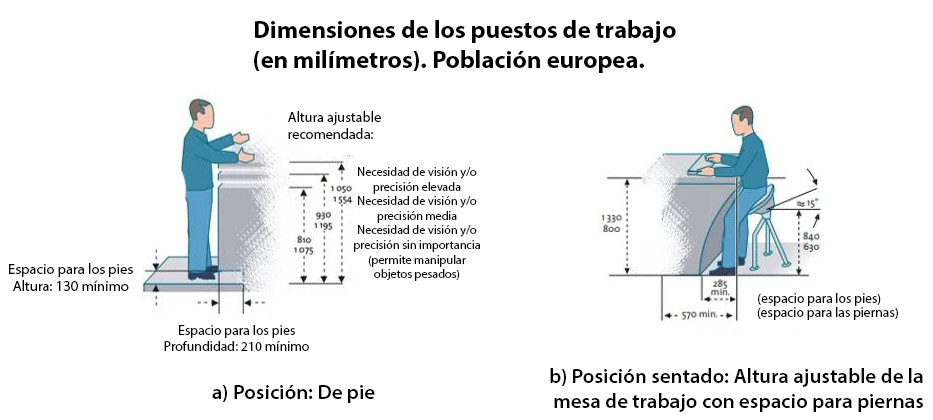

For a seated or standing workstation, the height should be between 81 and 107cm for handling heavy objects with little precision.

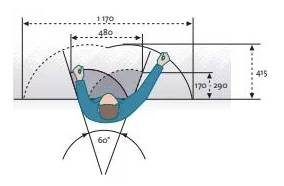

The essentials should be within reach, within 60°.

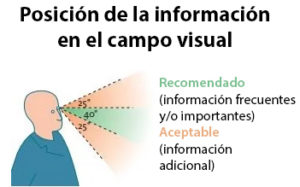

The essentials should be within reach, within 60°. Significant visual information should be placed at an angle of 40° from the horizontal line of the order picker. The instructions and possible control screen will be installed in this area.

Significant visual information should be placed at an angle of 40° from the horizontal line of the order picker. The instructions and possible control screen will be installed in this area.

The packing station structure

- The top shelf accommodates the most frequently used cardboard boxes or envelopes of different sizes (flat), which can be easily removed thanks to the dividers.

- The middle shelf has elements that are needed quite often: drawers, adhesive tape supply, tissue paper, label printer… Some customers put the air cushion dispenser box.

- The bars are used to place the filler packaging or labels (although it is optional).

- Display stand and document holder (for an internal packaging manual, for example) are placed at eye level according to INRS recommendations.

- When it comes to a company that packs a lot per day, a packaging system is installed directly on the table. This is possible with a simple paper filling system such as the Fill PackMTM or a more evolved Fill Pack TT®.

tip: depending on the number of hours spent at the packing station, we recommend the use of other accessories

- Anti-fatigue mats that relieve pressure on the feet and stimulate blood circulation.

- Stools; although this will depend on the nature and size of the products to be packed.

- Box conveyors that facilitate picking and minimise manual handling.

at Rajapack we are packaging experts, so if you are interested in a fully customised packing station for your needs, you are in the right place. We can design modular options adapted to your packaging process. Call 902 20 30 06 or send an email to contacto@rajapack.es.