La importancia de que los envíos lleguen siempre en perfectas condiciones a casa del cliente es un asunto vital en todas las empresas. Productos como el papel de seda, plástico de burbujas, virutas de papel y chips de relleno ayudan a rellenar y proteger el producto en los envíos. Nosotros queremos hoy hablarte de la espuma foam, muy recomendada para proteger productos frágiles, perecederos y pesados.

La importancia de que los envíos lleguen siempre en perfectas condiciones a casa del cliente es un asunto vital en todas las empresas. Productos como el papel de seda, plástico de burbujas, virutas de papel y chips de relleno ayudan a rellenar y proteger el producto en los envíos. Nosotros queremos hoy hablarte de la espuma foam, muy recomendada para proteger productos frágiles, perecederos y pesados.

A continuación, te explicaremos qué es la espuma foam, sus usos y qué tipos de foam hay, de esta forma aprenderás qué es lo más adecuado para tu empresa y para los productos que quieras proteger y podrás hacer frente a todas las situaciones con las que te encuentres a la hora de preparar tus envíos y de esta forma dar el mejor servicio a tu cliente.

¿Qué es la espuma foam y para qué se utiliza?

La espuma de foam puede ser de polietileno y poliuretano, se obtiene a base de espumar estos materiales con un gas que se inyecta a presión durante su fabricación.

Sus principales ventajas y la razón

p

- Polyethylene is rigid and hard.

- Polyurethane is soft and smooth.

foam

foam products and their uses

Foam reel:

- It protects against marks on fragile surfaces.

- It guarantees protection against possible impacts and vibrations caused during the transport of products.

- It adapts to the shape of your objects and facilitates packaging because it is flexible.

- It is made of low density polyethylene and is therefore lightweight.

- It can be used, for example, to separate products from the inside of a box.

- It can be purchased pre-cut in rolls or in a dispenser box, in sheets or in bags, as shown in the photographs below:

Foam foam profile

- Made of polyethylene foam.

- Excellent qualities: Flexible, shock absorbent.

- Resistant to humidity and temperature variations (from -40º to + 100ºC).

- Ecological and reusable: They do not contain CFCs or HCFc, recyclable.

- Easy to use: Cut to the desired dimension with the help of a cutter.

- Available in L-shape, high protection L-shape, U-shape and O-shape, as shown in the pictures below:

u-shaped foam profile

u-shaped foam profile

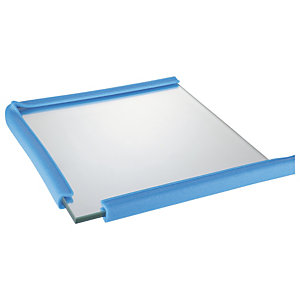

Polyethylene foam sheets

- Gives excellent protection, the material is cushioned, rigid and non-deformable, which recovers its initial shape even after several blows.

- Practical: Easily cut with a cutter or saw.

- Multi-purpose: For filling and separating products, cushioning inside boxes, etc…

- Ideal for separating products vertically and horizontally and can be easily cut with a cutter.

foam foam adhesive block

- Fixes your products: At the same time it guarantees perfect protection against knocks.

- Closed cell polyethylene foam, non-abrasive and high density.

- Ideal for separating flat products, prevents friction.

- Permanentadhesive side coated with a silicone paper.

- It is ideal for use as a foam filler as it is very versatile and can be glued to the box to create the shape you consider most suitable.

Instapak® Quick RT® expanding foam bag

-

- very simple: Manual, make the bag instantly without machines.

- Save space: Very easy to transport and store, polyurethane foam bags delivered flat.

- No machine required.

instructions for use

-

- Place the bag on a flat surface and hit point “A”, then point “B” to release the components.

- Press points A and B alternately 15 to 20 times to mix the two compounds.

- Place the bag inside the box and centre the product, keeping it in position until it is enveloped by the foam.

- Repeat operation 1 in a new bag, place it on top of the product and close the box to form the top protection.

foam filling machines

If you need an automated system for Instapack bags, Instapack filling machines may be the solution. There are two types, the Instapack Simple TM System and the Instapacker TM System.

Instructions for use

Both are easy to operate

- Select on the screen the amount of foam to inject, then cut the bag to be filled.

- Place your product on top of the foam bag.

- Cover your product with a second bag, the foam expands and fills the empty space.

instapack Simple TM System

- For small to medium throughput rates up to 100 cases/day

- Small footprint: Easy to install on a table or packing station

- Very easy to use: 6 pre-set programmes, practical control panel.

- Ergonomic: The system is easy to load from drums.

instapacker TM system

- For high throughput rates up to 500 cases/day

- Production of expanded foam in a bag that adapts perfectly to the shape of your products.

- Compact: Its small size allows it to be easily integrated into a workstation.

- Easy to use: Ergonomic display and preset programmes.

- Versatile: The amount of foam can be adjusted to protect all types of products.

- Optional work table with bottom panel and consumable tray for improved ergonomics and cleanliness.

rAJAPACK’MOUSSE Foam Box with Sleeve

- Double protection: 25 mm thick anti-scratch honeycomb polyurethane foam interior. Double layer of cardboard on the top and bottom. Kraft coated single channel cardboard, which ensures a perfect presentation and reliable protection.

- Open and close as often as you like: The inner case slides into the cardboard sleeve.

- Ideal for e-commerce: Use the same box for shipping your fragile products and possible returns.

- Easy to assemble without adhesive.

rAJAPACK’MOUSSE Foam Box

- Designed for fragile products: Electronics, telephones, photography, optics…

- Easy, safe and fast closing: With tab, to save time.

- No need for adhesive.

- Highly resistant: Made of single channel cardboard and coated with kraft.

- Up to three layers of cardboard in the corners to guarantee total security.

for more information about our foam products and all their fields of use you can call our packaging experts on 902 20 30 06, they will be happy to help you! Or if you prefer to send an email: contacto@rajapack.es