Big Data, machine learning, automation… These concepts have gradually found their way into different sectors of activity, but especially in logistics in order to provide the best user experience. Have you ever left a purchase halfway through because the delivery times were too long? For this and other reasons, seven out of 10 shopping carts are abandoned in e-commerce, according to the Baymard Institute. This problem is one of those that technology is trying to solve in the world of logistics. In this article we tell you how automation is revolutionising intralogistics and how you can use it to cut lead time.

What is intralogistics automation?

Intralogistics is one part of the supply chain. Specifically, it deals with all internal processes and movements of goods. All those actions that take place in the warehouse from the receipt of raw materials, their dispatch to the production lines, storage and the subsequent packaging of the products for dispatch are part of intralogistics.

Over time, the logistics industry has sought to evolve and modernise. To this end, technology has been used to improve efficiency, boost productivity and eliminate human error. One of the ways in which this has been made possible is through the automation of intralogistics.

By automating intralogistics, including the mechanisation of order picking in the warehouse, customer service is improved. Automating processes also simplifies decision making and allows the company to be prepared for possible peaks in demand.

Trends in intralogistics automation

1. Intelligent warehousing

Most distribution centres still operate with extensive use of conventional labour. This can be a problem, especially if the company’s workforce is limited, as tasks will not be performed quickly and efficiently. However, intralogistics automation is converging towards so-called smart warehouses. These spaces include automated storage systems, carousels, vertical lift modules and collaborative robots that improve the accuracy and speed of operations and enhance the quality control of goods.

2. Automated distribution channels

Through automatic distribution systems, when an order is received, a robot releases the product, which is transported by a conveyor system to the operator.

3. Articulated arm

These are robots that help in the task of sorting products, as well as packing them before placing them on pallets. Professionals can monitor the status of the task in real time.

Packaging solutions to automate intralogistics

If you have been thinking for some time about how to gain efficiency in logistics, automation may be just what you need. Here is our proposal of packaging solutions for logistics 4.0. Thanks to them you will be able to optimise space, increase productivity and reduce errors in this process.

- Case sealing machines. There are machines that will help you seal the boxes that you have prepared with your customers’ shipments. This will save you time and allow you to entrust other tasks to your staff. For homogeneous volumes, you can use a single-format box sealing machine, which will allow you to seal between 700 and 1,200 boxes per hour, or you can also opt for multi-format box sealing machines, if you work with a wide variety of types and formats of boxes. You may also find an electronic gummed paper dispenser useful, which provides you with fluidity in the handling of the adhesive to achieve total protection of the goods.

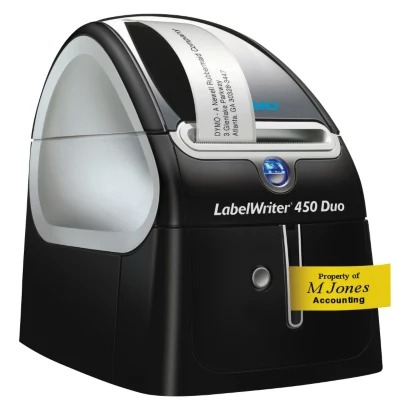

- Labelling machines. Once you have sealed your shipments, it’s time to label them. To do this efficiently, the LabelWriter printer is perfect. Easy to use, it uses high-speed software to print labels. But if you’re looking for something more compact, for lower throughput, and that can print up to 1,000 labels a day, take a look at our thermal printer.

- Pallet wrappers. To protect the goods inside the warehouse it is very useful to wrap the pallets. You can automate this task with programmable film wrappers that will allow you to memorise the different cycles, the number of wrapping wraps or the speed of the pallet – all advantages!

The packaging of orders is one of the main elements in any supply chain. By automating intralogistics , you will gain in productivity and efficiency when dispatching goods and, consequently, your turnover will increase. RAJA® will support you in your efforts: see our section on packaging machines and systems for sale and rental, or contact one of our specialists on 900 877 024 (Monday to Friday from 8:00 am to 7:00 pm).