Wrapping pallets gives security to the shipment of large orders, as the use of film keeps all the packages together. However, this task can be complicated or tedious, especially when the pace of preparation of shipments is high. Including a film machine can make your job easier, but do you know which one is best suited to the needs of your warehouse?

What are the advantages of a film machine?

If you are wondering what the benefits are before choosing a film wrapping machine, here are the reasons why it is worth investing in one of these machines:

- It reinforces the pallets. Thefilm increases the protection of the pallets during transport, preventing some of its elements from falling or other types of damage. Make sure you choose the right pallet.

- Avoid returns. A well-wrapped pallet has less risk of breakage and, therefore, reduces the rate of returned goods.

- Save material. The machine adjusts the necessary amount of film used, reducing waste to achieve EcoResponsible targets.

- It speeds up the pace. Using a machine allows you to automate processes in the warehouse.

- Reorganise teams. Not only will you free your workers from the task of wrapping pallets with film, but you will also be able to assign them to other functions.

- Reduces the risk of accidents. Its ease of use prevents injuries and musculoskeletal disorders (MSDs) in the warehouse, which also means a reduction in sick leave.

Types of pallet wrapping machines

These are the three types of film wrapping machines that you can find in our catalogue.

1. Pallet stretch wrapping machines with platform

Pallet wrapping machines with platform are the most economical references , but they require more space on the warehouse floor due to their rotating base. Their mast allows you to cover the highest pallets. Among the turntables you can choose the following:

- NOBEL EvoPac turntable film wrapper with manual brake. The simplest, most reliable and economical option.

- Manual brake film wrapping machine – Standard model. The most basic of the film machines, it is robust, reliable and versatile.

- Manual brake platesetter – Programmable model. Programming includes memorisable or manual cycles, back-up laps, platform and carriage speed and film unloading.

- Motorised pre-stretch film wrapping machine. Allows you to reduce the amount of film used in each cycle.

In addition, if you add an access ramp, you will find it easier to place the pallet on the surface.

2. Rotary arm film wrapping machines

The Newton Fix EvoPac turntable film wrapping machine with electromagnetic brake is ideal for tight spaces, as it takes up less space than the turntable. In addition, it also saves time, being able to prepare around 250 pallets a day. The arm rotates around the pallet and places the film with tension regulated by the electromagnetic brake. For correct operation, the machine must be securely fixed to the floor.

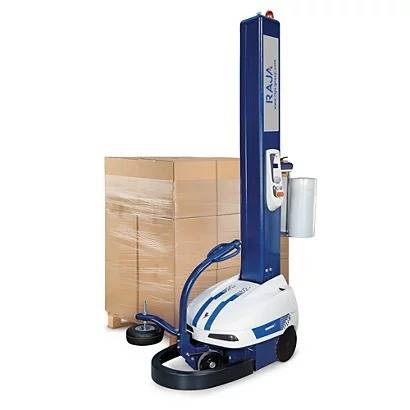

3. Film robots

In our catalogue you will find two types of film robots: the stretch film robot with manual brake and the stretch film robot with motorised pre-stretching. These film robots are also space-saving compared to turntables and rotating arms, because they can be stored wherever you want after use. They are easy to move and, as they are motorised, you can wrap the pallets wherever you prefer. In addition, they adapt to large pallets that do not fit on platforms.

What should you take into account when choosing a film wrapping machine?

Before choosing a type of film wrapping machine, you must assess the constraints and needs of your logistics activity:

- Warehouse space. The platform is the option that requires the most space. The robot is the machine that requires the least surface area.

- Distances. If you need to bring the machine closer to the pallet and not the other way round, the robot is your option.

- Budget. Turntables require less investment.

- Types of pallets. If the pallets do not have a standard size, you will have to use the filming robot.

- Rate of filming. Machines with turntables and rotating arms are electrically powered, a more suitable option for fast throughput rates compared to robots, which are battery powered and need to be recharged periodically.

- Products to be wrapped. If the contents of the boxes are fragile, you should consider that the rotating arm exerts more pressure than other machines.

- Warehouse environment. If you need to keep the floor clean on a regular basis, as is the case, for example, in the food industry, the rotary arm or the robot helps to keep the spaces clear.

Wrapping pallets precisely and securely is possible with RAJA®. Now you know everything you need to consider when choosing a film wrapping machine, but if you have any questions, please contact us – don’t hesitate to contact us !