Storage is defined as a process that consists of three main functions:

- receiving products from the supplier

- storage of products

- removal of products

By optimizing the storage of goods, it is possible to save the time required for retrieval and the associated financial costs and thus improve the company’s performance.

The basic methods of storing goods include, for example, the ABC method. The most well-known methods of material flow management include the LIFO and FIFO methods. These methods of warehousing and material flow management will be introduced in more detail below.

ABC method

The principle of this warehousing method is based on Pareto’s law, which states that 80% of the effects come from 20% of the causes – thus, applied to logistics, 20% of the stored items correspond to 80% of the total inventory value.

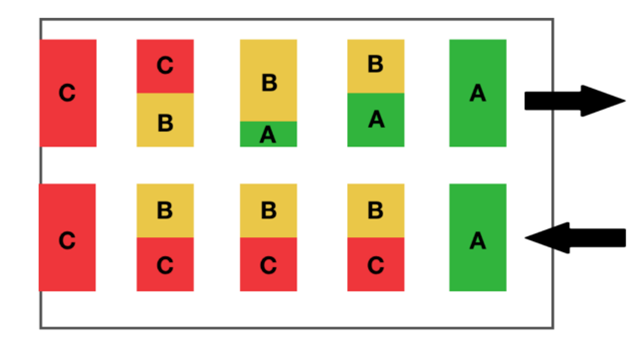

The ABC method therefore takes into account the turnover rate of a given item – the higher the turnover rate (the more frequently the product is sold), the easier and faster access to that item in the warehouse should be.

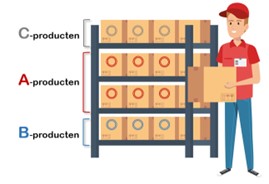

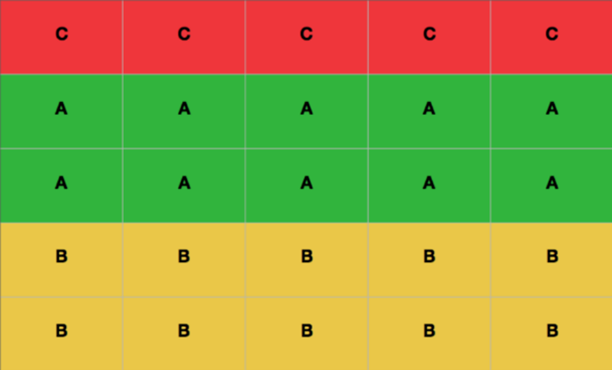

Products can then be divided into 3 categories:

- Category A – These are popular products that should be in a readily accessible location for quick retrieval.

- Category B – These products are picked less frequently.

- Category C – These are the least popular products and should be placed in less accessible locations.

In terms of individual shelves, it is advisable to place Category A products roughly in the middle of the shelf, Category B products on the lower shelf rungs and Category C products on the highest, less accessible, shelf rungs.

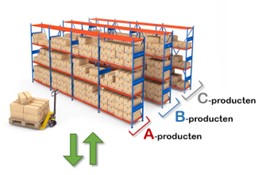

It is also possible to organise the whole warehouse according to the ABC method, with the A products close to the picking point, the B products behind them and then the C products at the end of the warehouse (furthest from the picking point).

FIFO and LIFO methods

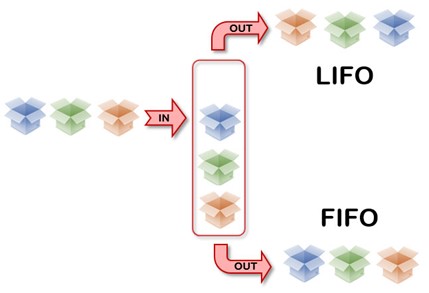

- FIFO method:

The abbreviation FIFO is from the English First In First Out or in Slovak – first in, first out. The principle of this method is simple and consists in removing goods from the warehouse in chronological order of arrival, i.e. the goods that are first in are also first out. This approach is mainly used in food warehouses.

- LIFO Method:

The abbreviation LIFO is from the English Last In First Out which means last in, first out. It is actually the opposite of the FIFO method. The principle of the LIFO method is as follows – the products that were stocked last are the first to be taken out. Thus, the items that have spent the shortest time in the warehouse are removed first. The main disadvantage of this method is that the old goods are still ageing. It is used for warehouses with materials such as sand, etc.

Everything you need for your warehouse, and much more, can be found on our website rajapack.sk.