What are the temperature and humidity conditions in which your products are shipped? Will the food arrive in perfect condition in order to be consumed? Where has the packaging passed before reaching its destination? Answering these questions is now possible with smart packaging. This type of packaging therefore features technology that has been developed to guarantee that your product is in perfect condition. Above all, throughout your entire supply chain. That is: from the moment the product leaves the warehouse until it is consumed or used by the customer.

In conclusion, smart packaging is the future of packaging and it is already very clearly present. The data prove it. For example, according to a study carried out by Market Research Future, Smart Packaging Market Research Report – Forecast to 2023 smart packaging represents a 46 billion dollar market worldwide. An annual growth rate of 5.16% is forecast for the period 2017-2023.

Smart packaging, what is it?

Smart packaging combines two different types of packaging:

- Intelligent Packaging: capable of monitoring the changes your products undergo when stored in their packaging. Both in their actual state and in external storage conditions.

- Active packaging: reacts when measures are taken to ensure the product is protected against these changes.

So smart packaging is revolutionising the world of traditional packaging. It offers your producer and the consumer a range of additional services. Above all, it goes far beyond a simple packaging that allows you to store and ship your products.

Intelligent packaging + Active packaging = Smart packaging

Smart packaging combines two types of containers and packaging:

1. Intelligent packaging or intelligent packaging

Smart packaging uses sensors and devices that help monitor the situation and the state of the product in real time. In conclusion, it is possible to measure:

- TTI, or temperature and time indicators. They tell you what temperatures a package has been exposed to and for how long.

- Degree of humidity.

- Level of degradation. Evaluates if a food, or any other product, for human consumption is still suitable for marketing and consumption of the same.

- Localisation. RFID tags control the location of your product. In addition, they also store all the information on where the package has been.

2. Active packaging

For example, active packaging combats any kind of threats that may arise. So it helps to prevent conditions that put the quality of your products at risk.

How does active packaging work? It normally emits a substance or absorbs a harmful agent present in the environment (water, oxygen, etc.) by detecting changes in lighting, pressure, temperature, humidity, etc. The aim is to keep your product in the best possible condition for longer.

Which sectors will benefit most from smart packaging?

For example, smart packaging offers advantages for the entire logistics ecosystem. Mainly in two sectors: food and pharmaceuticals.

Smart packaging for food

For example, the possibilities of smart packaging in food are impressive. One of the most innovative techniques is MAP (Modified Atmosphere Packaging). It consists of extracting the air inside the packaging and replacing it with a mixture of gases that have a protective effect on the food. In this way, their nutritional and organoleptic properties are kept intact for longer.

Smartpackaging for the food industry

Similarly, smart packaging in the pharmaceutical sector guarantees the safety and effectiveness of medicines. With NFC or bluetooth technologies, medicine packaging can interact with mobile phones or tablets. Above all, it shows you how to apply a treatment or warns you on the app that it is time to take your medicine.

However, smart packaging still has some economic and environmental challenges to meet.

Current solutions from smart packaging

In conclusion, we can help you to implement products in your company that detect whether a product has been handled properly or not. After that, you can take better care of the quality and safety of your shipments. Join smart packaging!

COLD ColdMark down temperature indicator

It is an indicator that is always active (it does not need to be activated). When it is exposed to a lower temperature than indicated, from 30 minutes, the window turns purple.

Rising temperature indicator WARM WarmMark

This is a high temperature indicator that is activated when the tab is pulled. The windows are coloured according to the time of exposure to a temperature above the ideal temperature.

IndicaShockWatch Impact indicator

This indicator is ideal for your most delicate products. In addition, if your product suffers an impact, the indicator marks on the central tube of the label a red shade.

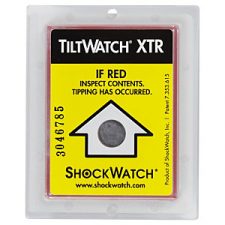

If your products are turned more than 90º, the indicator will change from black to red. In addition, it has a serial number to help you ensure the traceability of your products.

Are your products well labelled?