Firstly, concern for the environment in the packaging and logistics sectors has led to the emergence of Returnable Transport Packaging (RTP). Already, a large increase in the number of uses of this reusable packaging is forecast for the coming years. Thus, the increasing use of RPCs is already leading to process changes in the packaging and logistics industry. Above all, be prepared for the green revolution: this is all you need to know about this type of packaging and how you can integrate it into your business’ product management.

What is Returnable Transport Packaging (RTP)

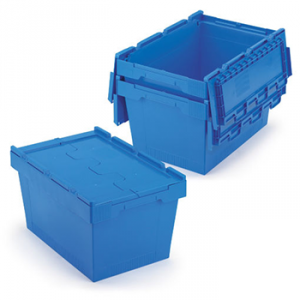

Returnable Transport Packaging (RTP) is packaging that is designed for the storage and handling of various types of products in repeated cycles. Unlike disposable packaging, which ceases to be used after it has fulfilled its duty, RPCs are taken away, stacked and returned to their company of origin so that they can be used again for transporting and marketing products.

Returnable Transport Packaging (RPC) in a warehouse

Similarly and with proper maintenance, RPCs can provide dozens and even hundreds of trips. In this sense, their use is quite evident in the food and automotive sector. However, concern for the environment and the desire to save on costs has aroused the interest of other types of companies. For example: pharmaceutical or electronics companies.

ERT logistics cycle

Definitely, ensuring that ERTs return to their company of origin and can be reused is a major concern. The following logistics chain process is usually followed:

- In addition to the price of the products, the producing or distributing company charges the receiving companies extra for the deposit;

- When the purchasing company incorporates the products in its warehouse, using its own packaging, or when it distributes them in shops and they are sold, it must return the RPCs to its supplier to recover the deposit;

- Depending on the type of products that are transported, the RPCs undergo a more or less rigorous cleaning, and the cycle starts all over again!

As a result, in order to correctly assess the costs of the activities in the logistics chain, it is necessary to define who is responsible for the execution of the RPC tasks. As well as a third person can also be identified, who is in charge of renting and maintaining the RPCs for external companies.

Similarly, it should also be taken into consideration that if the RPCs are pluggable, their volumetric weight on return will be considerably lower.

Advantages of expanding RPCs in the packaging world

Above all, with the maximisation of the use of RPCs in logistics activities the following advantages are presented:

- Respect for the environment. A lower consumption of disposable packaging reduces the volume of waste generated by the sector and, consequently, environmental pollution;

- Cost savings. Although it is true that a RPC is more expensive than disposable packaging, when the first one reaches a certain number of uses, it becomes more profitable and financially sustainable than the second option;

- Accessibility to products during transportation. Unlike traditional packaging, RPCs can be opened and closed several times to check the status of the products or extract part of them, at any point of the logistics chain;

- Simplification of tasks. Packing products is generally easier and quicker with a RPC than with a system based on cardboard boxes, straps, adhesive tapes, filling materials, among others;

- Sturdiness. Returnable transport packaging is safe and robust. They ensure that products circulate well protected against shocks and damage;

- Compatibility with smart packaging. Linking tracking systems or temperature and humidity control systems to RPCs is quite simple. In this sense, these systems can also be used in subsequent trips without the need to redirect them to another package.

Types of returnable transport packaging (RPC)

RAJA has a wide range of high quality stackable plastic boxes available, which include models with standard measurements for transport within Europe. Within our references you will find:

- Idealperforated plastic boxes for the transport of food, textiles, agriculture;

- Stackable bins made of cellular polypropylene. Resistant to water and chemical agents. Ideal for pharmaceutical, mechanical, electronic or textile products;

- European standard bins. That is: developed according to the standard measurements for European pallets;

- Nestable plastic boxes with lids. Stackable and nestable, perfectly palletizable.

In conclusion:

Visit the new website and bet on taking care of the environment with RAJA! We have the best eco-friendly packaging solutions on the market.