Above all,packaging fill er plays a crucial role in the tasks of packaging products in an e-commerce or simply for their transport. So if boxes, bags, envelopes and cases are used to store the contents; and adhesive tapes, glues and films are used for the proper closing of the package, the packaging filler is used as an element of protection for the products.

Mainly, the function of packaging filling is to ensure that the products arrive in good condition and are not damaged during the shipping and transport processes. This is made possible by the fact that it has a triple effect:

- By reducing empty spaces, it prevents products from wobbling inside the packaging that contains them, due to the movements derived from their transport;

- It absorbs shocks and impacts so that they do not compromise the integrity of the products;

- It is an additional layer that separates the contents from possible external aggressions, such as humidity, dust or dirt.

Therefore, at RAJA we want to help you make the most of all the possibilities of packaging filling for your business. With this post you will discover the importance of choosing the right materials, the different types of filling machines that are available in the market and the best practices you can apply to optimise your processes when preparing orders. In that sense, you just have to stay with us and read on!

The importance of choosing the right packaging filler

Since it adequately protects the products, the use of the right packaging filler has a positive impact on several aspects that affect the good performance of any business. In fact, why should you worry about choosing this packaging component with care?

- Presentation: the inclusion of the filling ensures a good placement of all the elements inside the box and its stability. The presentation to the customer in an organised manner is very important, as is the perception that the products you have purchased are perfectly protected;

- Loyalty: high quality packaging contributes to customer loyalty, and it is essential to use a filling that makes the shopping experience memorable. Today’s consumer is very demanding and values that their order is easy to unpack and that all packaging is made with environmentally friendly and recyclable materials;

- Differentiation: certain types of fillings can be personalised with the brand’s own colours, logos and messages. It becomes, therefore, one more support to develop your marketing strategy;

- Productivity: finding the right filler for the ideal packaging in your company or e-commerce and incorporating automatic systems will reduce order preparation time. In effect, this will result in greater productivity per operator and will also combat the prevention of musculoskeletal injuries that can occur in the warehouse.

As a result, the key to achieving these four benefits lies in the proper selection of the filling type according to each situation.

Types of filling for packaging

Do you know all the options we have available for packaging filling and protection?

Filling materials for traditional packaging

Bubble Wrap

Rolled bubble wrap as packaging filler is recommended for products that have right angles or sharp edges (furniture, knives, etc.) and for fragile products that can get damaged easily (plates, glasses, etc.), especially if they come in several pieces. There is also antistatic bubble wrap, ideal for electronic products such as mobile phones, tablets, computers or televisions.

Bubble wrap is a type of filling for packaging that is lightweight, economical and can be adapted to various formats. It is available in rolls, sheets and bags for easy use.

Expanded filler chips

The particles that are part of the filling chips are ideal for filling the irregularities inside the boxes. These particles help to compact the contents of the carton and prevent unwanted movements. They are an excellent complement to the shipment of fragile products, the protection of which is also used with bubble wrap in rolls or bags.

When your product is particularly delicate, the filling chips are a low-cost, original and highly aesthetic solution for additional security.

Pre-cut foam film, packaging filling

When comparing bubble wrap and foam film as protection for our orders, we point out that while bubble wrap is a popular and very effective solution for fragile products, when they have polished or shiny surfaces (as is the case, for example, with a mirror it is best to opt for foam film or bags.

Bubble wrap can leave marks on delicate surfaces, whereas foam is much softer and more environmentally friendly. On the other hand, foam is available in different presentations: in bags, in sheets and on a roll.

Filling materials for innovative packaging

Corrugated cardboard and kraft paper absorb shocks during transport. Thus, both prevent product movement and are suitable for less fragile products. In fact, kraft paper is the most common filling in packaging for cosmetics shops, parapharmacies and online perfume shops due to its versatility to hide gaps when the size, or shape, of each element is uneven.

Kraft paper offers a natural finish in shipments, as well as taking up little space and being recyclable and biodegradable. It is usually supplied in rolls that can be cut to size or in pre-cut sheets. In addition, it can be customised with corporate colours or with the printing of logos and messages.

Tissue paper

Tissue paper provides a neat presentation of products, especially those that are packaged as gifts. It is highly valued in clothing and cosmetics shops. It can be purchased in white or other colours and can be adapted to the brand communication. It is therefore the star of a memorable unboxing!

Air cushions

Air cushions are like an ultralight, modern and comfortable protection. Once inflated, they are composed, as their name indicates, of 99% air, so they take up very little space, both before use and afterwards.

Air cushions can be used in packaging machines and systems or in distribution boxes, ready for immediate use. In this way, they have become one of the preferred options for e-commerce in recent years. One of the main reasons is their ease of handling as well as their cleanliness. In addition, they are available in an Eco-Responsible version, manufactured with 20% recycled raw material.

Renature filling chippings

As an alternative to expanded polystyrene chips, cornstarch-based filling particles take an equally effective but more environmentally friendly position. They are very suitable for fragile and delicate goods, are 100% recyclable, biodegradable and compostable.

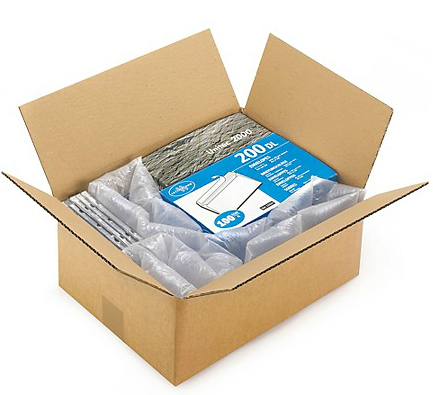

Filled packages

To further speed up the preparation of your orders, especially in businesses where packages with more or less constant volumes are sent, in RAJA’s catalogue we have two-in-one solutions: packaging that combines (boxes, cases, bags, envelopes) with filling (bubble wrap, foam, etc.) in a single product.

These packages with built-in filling also allow an elegant and sober arrangement of their contents to be achieved with very little effort. Check:

- Foam-filled mailbox. Prepared for the total immobilisation of the products. This product incorporates a polyurethane foam interior;

- Padded envelopes. For small and light products, suitable for sending by post and for enabling contactless delivery by depositing them in the recipient’s mailbox. In the case of Jiffy Green paper padded envelopes, you will find the most eco-friendly version!

Filling machines for packaging

With paper, air and foam filling machines and systems you can automate the protection of your products. If you want to optimise the preparation process of your orders, saving time and achieving a perfect presentation, this is your best solution.

Paper filling machines

Within the machines that produce paper filling, we find two types:

- Filling machines with paper to fill the gaps. These systems process the paper by stirring it, perforating it, to generate a filling with volume that covers the gaps and cushions the blows;

- Paper filling machines that wrap products. They create a soft cover, with a honeycomb texture, which favours a very aesthetic, attractive and Eco-Responsible presentation.

Thus, we highlight our WrapPak System machine, which offers an effective, original and environmentally-friendly protection.

Air-filling machines

Air-filling machines for packaging automate the inflation of cushions. This system is usually modular, programmable and compact, so it is very easy to install in a packaging station.

Foam filling machine

Machines that produce filling from expanded foam generate an adaptable cover that surrounds the objects, retaining them and eliminating the vacuum in the packaging. In addition, it does not leave marks, which makes it ideal for use with shiny surfaces, mirrors or electronic products.

Machines that produce filling from expanded foam generate an adaptable cover that surrounds the objects, retaining them and eliminating the vacuum in the packaging. In addition, it does not leave marks, which makes it ideal for use with shiny surfaces, mirrors or electronic products.

How to enhance protection through package filling?

Choosing the right type of packaging filler is extremely important, but it’s not everything! Taking some additional tips into consideration will help you further strengthen the protection of your products:

- In boxes and cases, choose those that are made of the most convenient type of cardboard. Pay special attention to the thickness: single corrugated card board is recommended for light shipments, while double and triple corrugated card board is best suited for fragile or heavy products, for long trips and for export;

- Add foam profiles or cardboard corners to preserve the corners and edges of frames, furniture, etc. Any impact on these types of products can damage them;

- Seal your packaging properly, for example with adhesive tapes. At RAJA, you have different types of packaging tapes available. For example, in polypropylene or kraft, reinforced, coloured or silent. If you want, you can also make your packaging tapes personalised to boost your brand communication;

- Use strapping tape to make it difficult for your mailings to be opened unwanted. This way, no one can view the contents or remove any product.

In short, if environmental protection is one of your biggest concerns, remember that within the different types of fillers there are eco-friendly products, specially thought out to minimise the impact of material waste on the environment.