Properly securing a parcel is a very important task – both for shipping and during the move. Various necessary accessories are used for this, e.g. tape, labels, parcel fillers. When dealing with heavy items of unusual dimensions, so-called foam profiles are useful. What are the characteristics of these protective elements? Are they only associated with the removal and transport sector?

What are foam profiles?

Foam profiles These are distinctive decorative elements made from foamed polyethylene. Their shape and dimensions can be adapted to fit various products, e.g:

- wall edges

- Shelf edges

- edges of furniture,

- electronics,

- paintings,

- protruding shop products.

Aluminium profiles have a very important application that should not be underestimated. They protect sensitive areas (usually sharp edges and corners, which can crumble on contact with something heavy or tear thin cardboard). The second task is directly related to people, i.e. couriers, parcel recipients, shipping warehouse workers. Foam profiles prevent painful skin contact with sharp edges.

How do you use foam profiles? This is a very simple question. No additional tools are required for assembly. All you need to do is select one piece of foam profile, which has already been shaped, and then attach it precisely to the sharp surface, e.g. using adhesive tape.

Foam profiles – characteristics

Universal foam profiles are very important representatives of basic packaging accessories. These protective elements are used by large industrial companies or shipping warehouses, as well as by individual customers who would simply like to protect their belongings in cardboard boxes during a move or renovation.

Foam profiles guarantee solid protection of the items being transported. Even if the route of the consignment is bumpy, there is no need to worry about damage. Foam profiles prevent the effects of vibrations, scratches, impacts – the contents will be intact. No wonder it’s a popular accessory among many online, mail order shops.

Foam profiles – the most popular types

Foam profiles can be seamlessly divided into several minor types – distinguished by their different shape, thickness, purpose and form.

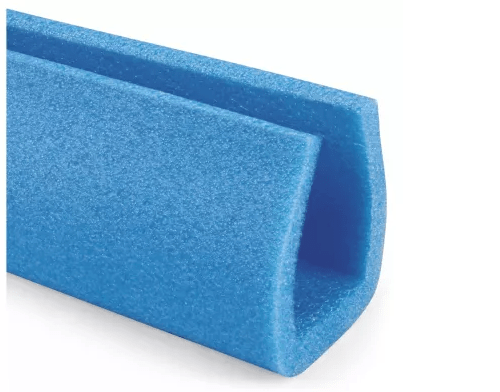

The most common and simple division concerns the purpose of these protective elements. The most common type of foam profile is “C ” – such pieces protect objects with complex shapes. Other foam pads – the “L” type – are used to protect the corners of goods. They usually have special cut-outs.

“U” foam profiles are – generally speaking – designed for securing flat loads. Thin and soft overlays with the name “WS” for the protection of glass elements, e.g. mirrors, windows.

Another division of foam profiles relates to shape. Foam overlays with holes in the shape of a circle or square are an interesting sub-type. Such protective elements will prove useful in packaging goods with non-standard shapes, e.g. sports balls. Round corners in the form of cylinders will effectively cover already packed items.

There are also professional half-roll corners with a specific design. What is it? On one side, there is a flat surface which can be easily fixed to a straight space. On the other side, on the other hand, there are curves – in a cardboard box, this layer would be facing outwards, as it has better protective properties.

Protective foam profiles – only at RAJA

In the RAJA shop you can find a number of polyethylene foam profiles, with a low density of 30 kg/m3. Those interested here are mainly dealing with the “U” and “L” types. The company specialises in providing modern, environmentally friendly solutions – mainly cardboard boxes.

Foam profiles – key benefits

Foam profiles are distinguished by their strength and low weight. Their lightness has its advantages – the total weight of the package in which they are placed does not increase significantly. The characteristic foam structure of foam profiles is characterised by its high elasticity. It never loses its cushioning properties – even when in contact with very heavy objects.

It is worth mentioning that the foam profiles have excellent vibration damping properties. Even if they deform (under heavy loads), they quickly return to their original shape. This is a kind of counterweight to classic polystyrene.

The expression “how to use foam profiles” is partly due to their non-trivial properties. First of all, they are impervious to moisture and water. They retain their flexibility in almost all conditions – even during extreme temperatures. They are non-flammable, anti-static and highly UV-resistant. Foam profiles are easy to clean. This property is conducive to their eventual reuse. Instead of throwing them away, they can simply be washed with compressed air or a jet of water. If they need to be reduced in size, this is not a problem – foam profiles can be cut with standard tools without fear of crushing or damaging them.

Foam profiles and fillers

Foamprofiles go well with other accessories – tapes, parcel labels and also fillers. Their bright, distinctive appearance does not detract from the look of eco-friendly and decorative parcel fillers.

Foam profiles – environmental impact

Foam profiles are made from foamed low-density polyethylene (LDPE), or polyethylene foam. It is an inert, non-toxic substance that does not emit chemicals. Polyethylene products should be segregated appropriately, i.e. put in the plastic bins. There are a number of advantages to this: properly segregated foam profiles can be quickly recycled. No waste is generated. Recycling contributes to a better environment.

Foam profiles – general significance

Foam profiles were developed for a specific purpose – to improve the quality of transport and removal services, as well as to raise safety standards in various industries. Generally speaking, they help to protect the contents of a parcel from damage. This also works the other way round – they prevent couriers or members of the public from injuring themselves or being injured by the sharp corners of the items being transported.

Application of foam profiles – is it just the transport industry?

Foam profiles are usually used in the transport and removal industry to protect the corners of walls, machinery and equipment. They are indispensable in any situation – they are useful for both mass production and individual orders in less popular mail order shops. However, that is not all.

Foam profiles are used, among other things, in the furniture industry – to protect boards, windows, glass and tabletops. There is no shortage of them in warehouses, industrial halls, underground car parks, logistics companies and international car rental companies. These protective elements are also useful in domestic realities – to protect the edges of furniture. This is a particularly important function in those homes where there are small children, who are exposed to the sharp edges of the furniture.

Foam profiles are also used in industry – as an alternative to metal, plastic protection. They can protect garden bays, gates, countertops and car windscreens.