Packing tapes, as the basic variety of adhesive tapes, are widely used in the logistics, storage, removal and service industries. They are also used in households. However, manually applying adhesive tape to a parcel can take a lot of time and effort – especially in the warehouses of e-commerce companies, where up to several hundred packages are sealed every day. A so-called packaging tape dispenser comes to the rescue. What are its characteristics? How to put the tape on the dispenser? How does it differ from a similar-sounding stretch film dispenser?

What are adhesive tape dispensers?

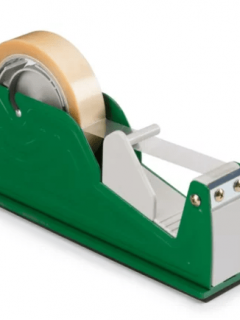

Adhesive tape dispensers (adhesive tape dispensers) are devices with a characteristic plastic (usually) construction. Their purpose is to facilitate the use of adhesive tape by the user – to make the whole process both efficient and ergonomic. Adhesive tape dispensers help to tighten the tape while it is being applied to a surface, so you can count on high quality and aesthetically pleasing adhesive bonding. They lack sharp knives to cut the sticky material, which increases user safety.

Dispensers are indispensable for time-saving and ergonomic work. They are therefore in demand in logistics warehouses and mail order warehouses, where warehousemen dispatch many consignments. The use of this inconspicuous accessory brings tangible financial benefits.

Design of a classic adhesive tape dispenser

The basic components of any adhesive tape dispenser are: handle, tape dispenser (drum), roller, presser (tensioner), serrated blade. The handle is the part that holds the equipment to a particular surface when sealing a package. A strip of tape slides gradually along the roller – as it unrolls. The presser is used to hold the tape close to the roller. The rotating tape feeder (circular or near-triangular in shape) is above the handle; it holds the tape in place. Knowing the basic construction of this useful damage, you will already know how to put adhesive tape on a dispenser.

Types of dispensers

Adhesive tape dispensers can be divided according to the width and the type of tape used. Most commonly, we talk about dispensers for office tape and packaging tape. The first dispenser, which has a very simple design, has a special blade that makes it easier to tear off pieces of adhesive tape (the kind used in office spaces). The dispenser must be placed on a level surface for the whole process to take place correctly.

Characteristics of packaging tape dispensers

Ergonomic packaging tape dispensers are emerging in the e-commerce industry. They facilitate the packing of parcels. Both their design and the way they are used have been well optimised in terms of time. Shipping wholesalers who deal with this tool on a daily basis know how to put tape on a packaging tape dispenser.

Popular packaging tape dispensers (handheld) are equipped with a comfortable, ergonomic handle, a blade (often shielded by a special protective flap) and a drum onto which the roll of tape is applied. The pointed, sharp part not only has the task of cutting the appropriate length of adhesive tape, but also of regulating the tension between it and the dispenser. These devices weigh very little and operate silently. Their distinctive handle is designed to adapt perfectly to the user’s build and function. The packaging tape dispenser can be operated with one hand. Some of them are additionally equipped with a mechanism that controls the unwinding of the tape.

Features of office tape dispensers

Office tape dispensers(table top office dispensers) are used in the service industry, offices, offices, homes. Some of them have a non-slip base to ensure a stable position on the desk. They are small devices. They are usually adapted to rolls of adhesive tape of different widths.

How do I apply packaging tape to a packaging tape dispenser?

Affixing packaging tape to a packaging tape dispenser is not a difficult task. If there is a roll of old tape on the dispenser, the user has to remove it – making sure that there is no remaining adhesive material. This is very important. Residue from the old adhesive tape could block the device. The new roll of tape must not be inserted in any arbitrary way – above all, the adhesive side must be facing downwards; so that the smooth, non-adhesive part moves freely on the guide roll.

Now begins the close part, answering the question of how to put the tape on the dispenser. Unwind a piece of tape a few centimetres long, which you guide behind the cutter blade (by first gently pulling back the tension lock), and then carefully place the roll of packaging tape onto the drum. The tension between the lock, the roll and the blade must be adjusted – this is very important. If you need to increase it, turn the tensioner clockwise. If, on the other hand, you want to reduce the tension between the dispenser components, go in the opposite direction.

How do I put adhesive tape on an office tape dispenser?

The office tape dispenser works in a similar way to the model designed for packaging tape. The first steps are identical – getting rid of the previous roll of tape, and making sure that no tape remains in the dispenser. The user has to unroll the new roll of tape by a few cm and place this piece of tape on the drum (adhesive side down). Then place the reel in the dispenser body and lock it (if the dispenser in question has such a lock). It is also important to secure the blade – remember to do this after each use of the equipment.

Advantages of an adhesive tape dispenser

Adhesive tape dispensersare already almost a mandatory part of the equipment of any warehouse, belonging to an online shop, mail order business – in other words, where packaging (and other) tape is constantly used on a daily basis. With tape dispensers, employees no longer have to seal packages by hand. This saves them a lot of time. They can focus on more important things.

The construction of the dispensers influences their advantages. The entire construction keeps the tape in a slightly unwound position – thanks to this, there is no need to worry about unwinding it again after each cut. The presence of pressure rollers influences the perfectly flat application of the tape (no folds, no air bubbles). The toothed blade allows the tape to be cut evenly at any time.

The dispensers are rather handy and lightweight. They have a handle that is easy to hold in the hand (these are mainly so-called hand dispensers). Thanks to them, the complete sealing of a package does not require physical effort (just a few hand movements are enough). The dispenser is indispensable in a wholesale environment, where warehousemen have to seal up to several hundred packages a day. Doing this would be impossible with their own hands alone.

Stretch film dispenser – so similar, yet so different

Some people, unfamiliar with packaging or parcel storage techniques, confuse the two terms ‘packaging tape dispenser’ and ‘stretch film dispenser’. These are two completely different pieces of equipment which only have coinciding names. You can therefore be sure that knowing how to put adhesive tape on a dispenser is of no use. The two tools are distinguished by their different designs and operating mechanisms. However, they have a similar purpose – to precisely cut a piece of adhesive tape or stretch film, which will then be applied to the carton. Do you know how to use stretch film and related accessories?

An alternative to the stretch film dispenser are ergonomic and easy-to-use wrapping machines (manual, automatic or semi-automatic). Thanks to them, cartons and goods can be secured even faster and better with stretch film (for transport, sorting or storage). If you do not have access to any cutting aid (i.e. dispenser, wrapping machine, wrapping knives), you do not have to give up – just start wrapping a particular parcel or goods with stretch film manually. Manual handling does not mean inferior results. It’s just that the packer has to be prepared to take longer to do the job.

If you want to learn more about the topic, read: Dispenser, wrapping machine or manual stretch wrapping?

The best dispensers – only at RAJA

The RAJA company is a dynamically developing enterprise, well-known in the packaging industry. The assortment here is very extensive and diverse. Therefore, interested persons should not have any problems finding dispensers for tape (packaging tape, reinforced tape, woven tape, office tape, rubberised tape). As far as dispensers for stretch film are concerned, at RAJA you will find metal dispensers, plastic dispensers and dispensers for mini rolls.