Cardboard packaging is an environmentally friendly solution, useful in the transport, removals, shipping, e-commerce industries. There are several main types of boxes – the way they are assembled looks different depending on the model. What is worth knowing about the different types of cardboard boxes? How to fold cardboard boxes correctly?

The most common types of cardboard boxes

Cardboard boxes for storage and mail order can be divided into several basic types. The most popular of these are:

- Flap cartons – consist of several distinctive flaps, placed at the top and bottom. Such boxes are sealed with adhesive tape. They are made of 7-layer, 5-layer or 3-layer cardboard. They are widely used for removals and in the transport industry. Flap cardboard boxes enable fast and efficient shipping and storage of bulky items. They are not disposable – their properties (durability and strength) guarantee repeated use.

- Folding cartons (die-cut) – boxes closed with tabs (special grooves implemented), which allow express closing. Their name derives from the die-cutting machine used in the manufacture of each box. These boxes are usually made to individual customer specifications. They can be of any shape or size.

Other types of cardboard boxes are die-cut boxes, telescopic boxes, automatic boxes and boxes with a lid. The first type is unique, created to meet the needs of a particular customer – die-cut cardboard boxes are often used in the advertising industry. They are cut to the dimensions of specific products. Usually folding die-cut cardboard boxes do not require the use of adhesive tape.

Relatively universal telescopic cardboard boxes have a rather specific form – they are oblong. Their length is adjustable (from a few to several centimetres). They are mainly used in the e-commerce sector. Telescopic cardboard boxes can accommodate several ordered products, which reduces the costs associated with having to purchase several cardboard boxes of different sizes.

Automatic cartons resemble façade boxes, incorporating a strip of tape. The folding of cardboard boxes in this form does not require additional tape to secure them from the outside.

Cardboard boxes with a lid are decorative pieces used for packing small items (usually gifts). They are closed with a characteristic lid. They are most often made of corrugated cardboard.

What are the most common materials for cardboard boxes? Ecological packaging

Good quality cardboard boxes – regardless of the type – should be manufactured from environmentally safe, natural materials. Such a need arises with the growing awareness of people – keenly interested in climate, nature conservation. Ecological packaging is made of plastics that decompose easily and can be recycled.

Among the cardboard boxes used for transport and shipping, the term “corrugated cardboard” or “solid cardboard” is most frequently used. Both materials can undoubtedly be described as environmentally friendly. Other natural materials include paper (recycled), sugar cane, biopolymers.

Corrugated and solid cardboard – characteristics

Cardboard can be single-layered or multi-layered. The solid version is a single-ply sheet of paper about 1 mm thick. It is a lightweight material, yet strong and resistant to various mechanical damages. Solid cardboard is used for those cardboard packages in which lightweight products are transported, e.g. cakes, medicines, underwear.

Corrugated cardboard is much thicker and stronger than its predecessor. It is characterised by its stiffness and resistance to bending. It can reach a thickness of up to 6 mm. Corrugated cardboardboxes are most often made of 3-ply (E, B, C wave) or 5-ply (EB, BC wave) cor rugated cardboard.The boxes with a lower thickness can be used to carry glass objects, lightweight white and brown goods and shoes. On the other hand, the stronger 5-ply cardboard is used for removals and for transporting heavier household appliances, white goods and unassembled furniture.

RAJA ecological corrugated cardboard boxes

In the RAJA shop you can find many ecological cardboard boxes – fully environmentally friendly. The most common are facade cardboard boxes and boxes made of 3-layer, 5-layer, 7-layer cardboard. There is also no shortage of flat boxes, long boxes, reinforced boxes, boxes with automatic bottoms, height-adjustable boxes and accessories (ecological wrapping paper, cardboard tags, cardboard safety corners, bags and paper sacks, book wrappers).

Check out our recent article, why you should choose ecological cardboard boxes and packaging.

The most important advantages of all cardboard boxes

The undeniable advantage of all cardboard packaging is its naturalness. Corrugated and solid cardboard can be recycled without problems. In addition, only environmentally friendly water-based inks with no negative impact on the environment are used in the creation of prints and decorative elements on cardboard boxes. It is also worth mentioning the high resistance of cardboard to damage and the possibility of using cardboard boxes in many industries.

Folding flap cardboard boxes – how to do it?

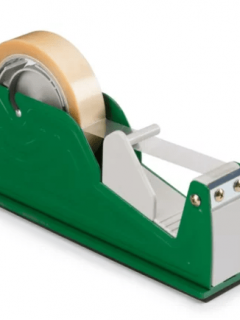

When folding flap cardboard boxes, a strong adhesive tape. In the initial phase, you get the cardboard box in a flat form – it is only by using your own hands and adhesive tape that you give it the right shapes.

The first step is to bend the sides of the cardboard box outwards. Carefully bend the shorter and longer flaps inwards and then join them together with sticky tape – apply it very carefully along the joining of each flap. Do not forget the pieces of the outer sides of the flap cardboard boxes. The tape must not only cover the inter-flap joints.

How to fold cardboard boxes?

The folding of flap boxes looks much different – a lot depends on the model. As with flap boxes, at first you are only dealing with a flat form. The first step is to align the side walls vertically. Then comes the more difficult part – the back wall of the carton has to be folded inwards. Importantly, this step is done while holding the side walls with the other hand.

In order to close the facade cardboard box completely, the front wall must also be folded in – in a similar manner. Such a box is closed using special caps. If the box is to be used for shipping a product, it is necessary to additionally seal the top wall with the side walls (between them). Adhesive tape is ideal for this purpose. This will ensure that folding cardboard boxes does not open during transport.

Proven method for folding telescopic cardboard boxes

The telescopic carton is assembled very similarly to the flap carton. There is the only difference between the two packages – the telescopic carton consists of two parts. The first step is to swing all the sides of the box outwards. Then you have to bend the flaps inwards and seal them firmly with adhesive tape. Employees of shipping and transport companies have a tried-and-tested patent for the extra security of the telescopic carton – they don’t forget that there are several packages in it that can move around during transport.

The method is very simple. You put a smaller box in an even larger pack, adjusted to the length of the items. Secure the combination in this way with tape at the end.

How to assemble other cardboard boxes?

Folding an automatic cardboard box can be done without the use of adhesive tape. The whole procedure looks similar to the folding of a façade cardboard box. However, remember – you do not use tape.

Folding gift boxes with lid is also very simple. First, you bend the longer sides of the box and fold inwards. Then you perform the analogous step – this time bending and folding only the shorter sides of the box, while inserting the characteristic tabs into the specially profiled holes placed in the texture of the cardboard.

Check:

- What to use 5 layer cardboard boxes for?

- 10 features of the best cardboard boxes for packaging and sending parcels

- Height adjustable cartons – advantages