Time is money! This is the sure truth in the world of logistics, and it is absolutely necessary to optimise the number of orders per hour and shift. At every step of the packing process, our experts will give you advice on how to save seconds and energy in the warehouse, so that you can pack, protect and seal your parcels more efficiently.

Before we start, take a look at their own packing process and read our 2 scenarios:

The importance of deliverability

A disappointed customer is a customer who will most likely never return or buy from you again. All sales and marketing strategies are wasted if the customer’s expectations are not met at this critical stage; so you must deliver quickly and you must deliver with quality

If a customer is dissatisfied, it means that, for some reason, they had a bad experience and will not buy from you again. The experience leading up to the purchase, no matter how painless, has been forgotten because the delivery did not meet expectations. Delivery is as important as the product.

Is your business affected by the season?

I B2B- så vel som B2C-markedet, er julen en sesong der kundene forbereder seg annerledes enn resten av året. Ta brettspillbransjen for eksempel, de har stort sett to nøkkelperioder de må forberede seg ekstra nøye på. Allerede fra perioden mai til juni distribuerer de sine bestselgere i påvente av salgsrushet i jula. De sender pallevis av gods i en kort periode til forhandlerne sine for å forberede seg på høysesongen.

Den andre betydelige lagerbeholdningen går direkte til salg for nettbutikkene på slutten av året. Dette er ren B2C-logistikk med fokus på rask leveranse til kunden. De må levere fort og forsikre seg om at forsendelsen kommer frem til sluttbruker i god stand, hvis ikke går kunden til en konkurrent neste gang.

Avhengig av hvor mye sesonger påvirker bedriften bør man alltid ruste opp arbeidskapasiteten og gjøre lønnsomhetsberegninger for høy- og lavsesong.

Package speed affects delivery time

Pack, protect and seal the goods. If you increase the efficiency of the packing team and multiply the efficiency by the number of orders, the savings and overall gains will be quite significant

Summary:

#1 Choose the right packing material#2

Protect faster and better#3

Seal your packages quickly and properly#4

The centre of the package; the packing table.

1.Choose the right packing material for the best packing process

The choice of packing material affects packing speed. Some choices may seem trivial, but for the packing team it can save seconds, resulting in more orders packed per hour without extra effort. The energy saved can be used in other areas of the packing process, such as quality checking of the shipments to reduce errors and defects.

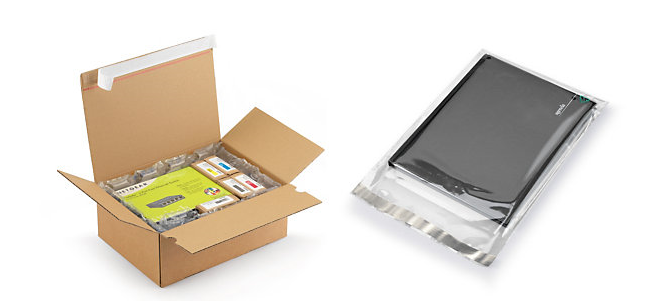

Switch to envelopes and e-commerce bags.

Where possible, think about how you can improve the packaging material. If switching from envelopes to envelopes and e-commerce bags is an option, there are two clear benefits

:Fast packing – You save time. The bags are ready to use compared to putting together an envelope.

Transport costs – Bags are lighter. Both weight and volume are reduced for the shipments, which means that transport costs also go down.

Some people think that envelopes and e-commerce bags are limited to low-value goods, but the fact is that the limitations can only be size or type of product. E-commerce bags are a good core product, but carton and cardboard bags are of course also good alternatives, for example for international shipments. Most net shops prefer cardboard packaging, especially double corrugated.

Our automated bundles will revolutionise your parcel process

Three benefits of switching from regular cardboard boxes to automatic boxes

:Save time: the boxes are assembled 2.5 times faster than regular boxes. This makes a big difference in the packing process.

Save energy: they are also 2.5 times easier to assemble. Your packing team will be grateful if you switch to automatic boxes! Just take a look at this video if you haven’t already.

Save space: our customers have commented that they used to assemble several boxes at a time up front, but now they can easily assemble automatic boxes as needed – and save storage space.

2. Protect faster and better

Protective packaging is something to think about to protect products during transport. Here are some suggested solutions that will reduce packing time and resources associated with the packing process:

Perforated bubble wrap

One way to save time when using protection is to reduce unnecessary tools. Perforated bubble wrap eliminates the need for a work knife. Watch our video on perforated bubble wrap vs regular bubble wrap.

Bubble bags with self-adhesive closure

Not only does the bubble wrap cover the product on all sides, it is also quick to seal so the product stays safe and secure.

Tip: Bubble wrap with self-adhesive strip is perfect for packaging products with an awkward shape. The product can easily be put in the bag, tear off the strip and close.

If you have products with an unfavourable shape, is customised packaging an option?

If large numbers of your orders consist of products that don’t fit in standard boxes, it would be ideal to use packaging that fits optimally. Customised packaging not only saves you the amount of protective packaging you use, but also packing time.

Best practice with bespoke packaging.

Packaging that fits the product best prevents movement and reduces damage. Tailored packaging therefore fits like a glove and reduces the amount of protection you would normally use. This should be assessed as part of the packing process. Here are three tips to remember

:- Think about the environment: where can you be “greener”? Tailored packaging reduces unnecessary overuse of packaging materials. –

Think logistics

: efficient packaging means lighter goods, optimised pallet packing and reduced transport costs

.

Send us an enquiry at post@rajapack.no or call us on 406 93 400 if you would like a no obligation quote.

Protective packaging systems

Protective packaging machines are ideal for e-commerce businesses that process multiple orders in large quantities. Once a packaging machine is installed, you’ll often find that the machine will pay for itself quickly as the speed of the packaging process will be much higher. Most importantly, it will help eliminate the need to hire additional staff, even as the packaging process speeds up.

It’s understandable that it’s daunting to look for packing machines when you’re not sure what you’re looking for. With our packing machine guide, you can easily find the packing machine that suits your needs. If you have any questions or need advice, please contact us at 406 93 200 or post@rajapack.no.

3. Seal your packages quickly and correctly

Sealing is crucial to keep your packages safe and secure during transport. We’ve put together some suggestions to secure the contents of your shipments while saving you time!

Can you seal a parcel without using parcel tape?

Yes, it is possible not to use packing tape, and it can save both time and money. Tape for your own use needs to have space in your warehouse and you need to keep track of supplies so you don’t run out. E-commerce bags and mailing bags are available with adhesive tape and this drastically simplifies the packing process. In addition, you will save warehouse space and reduce the amount of tape used in your business. Look out for packaging with adhesive tape.

How to benefit from gummed paper tape?

You may not be aware of this packaging product, but gummed paper tape is one of the most effective and environmentally friendly ways to secure your packages. Amazon, one of the largest e-commerce companies uses paper tape on all of their shipments, and it’s also custom made with their logo printed on the tape – two fantastic benefits!

Tip: We recommend using a tape dispenser for all parcel tape. For gummed paper tape, use a manual tape dispenser designed for gummed paper tape.

Gummed paper tape is made of pure kraft paper with an effective and odourless adhesive that sticks extra well to corrugated board, paper and cardboard. Therefore, there will be obvious damage to the ash if the tape is attempted to be removed.[

4. A centrepiece of the packaging process; the packing table.

Some may call it a workstation, a packing table or a packing station. Regardless of the term, it is an area for packing, preparing packages for shipment and then shipping the packages out. It allows you to be organized, efficient and prepared, and is more than a regular worktable. It provides a workspace with access to components and equipment that help you with wrapping, sealing and strapping. Such a station will help you with a smooth operation.

For more information on workstations and to find a solution that suits you, contact a packaging expert on 22514000 or post@rajapack.no