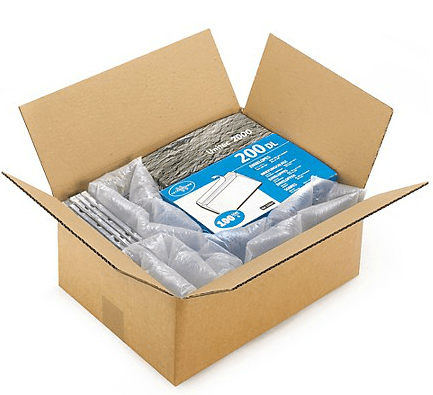

Packing is an important consideration for all online shops that pack and ship goods to their customers. Whether the shop uses boxes, bags or envelopes to transport the goods, packing is necessary to protect the contents. Of course, the need for protection varies depending on the product the online shop is shipping. The primary function of packing is to ensure that the products reach the customer in good condition and are not damaged during transport. This is achieved by:

- Packaging fill absorbs shocks

- By reducing voids in the package, it prevents the products from moving inside the package

- There is an extra layer that protects the products from e.g. moisture or dust.

We at RAJA can help you choose the best package filling and protection for your products. In this article, we go through the importance of choosing the right packaging filling and show some different types of filling material. We also look at some machines for packaging filling and protection, and give some tips on how to optimise the packaging process.

The importance of choosing the right packaging fill

As it provides good protection for your products, pack fill has a positive impact on important parameters such as shrinkage and customer satisfaction. Several reasons why it is important to choose the right packaging fillers are:

- Presentation: Packing the products with the right packaging fill ensures that all the contents of the box are well positioned and remain stable during transport. It contributes to a good first impression for the customer opening the package that the contents of the package are well organised and that the products are well protected.

- Loyalty: High-quality packaging contributes to customer loyalty, and it’s a good idea to use a filling material that makes the shopping experience stand out. Today’s customers are demanding and appreciate that products are easy to unpack and that all packaging is made from environmentally friendly and recyclable materials;

- Differentiation: Some types of packaging fillers can be customised with the brand’s own colours, logos and messages. Thus, pack fillers can also help strengthen your brand.

- Productivity: Finding the right type of packaging fill for your packaging process can speed up the packing of orders, especially if you also choose to use a packaging machine. This can lead to improved productivity and better ergonomics in the warehouse.

Types of packaging fillers and protection

Are you familiar with all the possibilities of parcel stuffing?

Filling materials for traditional packaging

Bubble wrap

Bubble wrapon a roll is recommended for products that have right angles or sharp edges (furniture, knives, etc.) and for fragile products that can be easily damaged (plates, glasses, etc.), especially if they come in several pieces. There is also anti-static bubble wrap, ideal for electronic products such as mobile phones, tablets, computers or TVs.

Bubble wrapon a roll is recommended for products that have right angles or sharp edges (furniture, knives, etc.) and for fragile products that can be easily damaged (plates, glasses, etc.), especially if they come in several pieces. There is also anti-static bubble wrap, ideal for electronic products such as mobile phones, tablets, computers or TVs.

Bubble wrap is a type of packing material that is lightweight, economical and adaptable to different formats. It is available in rolls, sheets and bags for easy use.

Bubble wrap is also available in recycled plastic, which we recommend for environmental reasons. There is also an equivalent paper product: Paper bubble wrap.

See all variants of RAJA’s bubble wrap here.

Packing chips

Packing chips are ideal for filling voids inside boxes and prevent unwanted movement of the goods. They are an excellent complement for shipping fragile products, often combined with bubble wrap. Packaging chips are an affordable and aesthetic solution. The new eco-friendly packing chips are made from 100% biodegradable corn starch and have a fresh green colour that looks great.

Foam film in sheets

Foam foil is an alternative to bubble wrap, and when comparing these products it is worth mentioning that foam foil is particularly suitable for products that have polished or glossy surfaces. Examples could be pictures in glass frames or mirrors. Bubble wrap can leave marks on delicate surfaces, while foam is softer and more environmentally friendly. Foam film is available in different versions: in bags, in sheets and on rolls.

Foam foil is an alternative to bubble wrap, and when comparing these products it is worth mentioning that foam foil is particularly suitable for products that have polished or glossy surfaces. Examples could be pictures in glass frames or mirrors. Bubble wrap can leave marks on delicate surfaces, while foam is softer and more environmentally friendly. Foam film is available in different versions: in bags, in sheets and on rolls.

Filling materials for innovative packaging

Corrugated cardboard and kraft paper absorb shocks during transport. This prevents product movement and is suitable for less fragile products. In fact, kraft paper is the most commonly used packaging filling for online pharmacies and cosmetics shops. These stores often ship products that are of different sizes and shapes, making kraft paper a very flexible and suitable material.

Kraft paper gives a natural look to the package, as well as being space-saving, recyclable and biodegradable. It is usually supplied in rolls that can be cut to size or in pre-cut sheets. In addition, kraft paper can be customised with your company’s colours or printed with a logo or different messages.

Tissue paper

Tissuepaper provides a neat and elegant presentation of products, especially those wrapped as gifts. It is therefore often used by clothing and cosmetics shops. It is available in white and a variety of other colours and can thus be easily adapted to the brand. Tissue paper is therefore the star of a memorable unboxing experience!

Paper strips and newspaper shreds are other paper options that offer both good protection and an elegant presentation of the products, and both types are therefore well suited for gift wrapping.

Air cushions

Air cushions are an ultra-light, modern and comfortable protective material. Once inflated, the pads are composed of 99% air, so they take up very little space, both before and after use.

Air cushions are an ultra-light, modern and comfortable protective material. Once inflated, the pads are composed of 99% air, so they take up very little space, both before and after use.

Air cushions can be used in packaging machines and systems or as perforated sheets, ready for immediate use. The material has become one of the preferred options for e-commerce in recent years, and one of the main reasons is that they are so easy to use and clean. In addition, they are available both in paper version and in plastic, both recycled plastic and bioplastic.

Pre-filled boxes and envelopes

To further streamline packaging, RAJA can also offer various special boxes and envelopes that combine packaging and filling in one and the same product. With these solutions, you get a good organisation of the content with very little effort. Take a look at:

Padded paper envelopes – the greenest choice. These envelopes are filled with a honeycomb-structured paper padding and can therefore replace bubble envelopes. Since both the outside and the padding are made of paper, the envelopes can be easily recycled: the whole product can be disposed of in the paper waste.

Jiffy green padded envelopes are another option. These are suitable for small and lightweight products sent by post.

Boxes with foam inserts. These can be used for total fixation of the products. The boxes are filled inside with a polyurethane foam.

Bubble envelopes – envelopes and bubble wrap, an all-in-one solution.

Packaging machines for filling and protection

With paper or air filling machines, you can automate the protection of your products. If you want to optimise the packaging process, save time and achieve a perfect presentation, this is the best solution, especially for larger online shops that ship a significant number of orders every day.

Paper filling machines

Within the machines that produce paper filling, we find two types:

Within the machines that produce paper filling, we find two types:

- Machines that fill with paper to fill in voids. These machines produce package fillers that protect the products inside the package from impact.

- Paper filling machines that wrap products. They create a soft cover, with a honeycomb structure, which provides an aesthetic and environmentally friendly presentation of the products.

RAJA offers a range of different paper filling machines, see an overview here.

Air filling machines

Air filling machines automate the inflation of air cushions. These machines are often compact and easy to install at a packing station.

Air filling machines automate the inflation of air cushions. These machines are often compact and easy to install at a packing station.

See RAJA’s air filling machines here.

How to improve protection through parcel stuffing?

Choosing the right type of packaging fill is a good start, but it’s not enough. Here are some tips on what to consider to best protect your products:

- Choose boxes that are made of the right type of cardboard for your products. Pay special attention to the thickness: Single corrugated cardboard is recommended for lightweight shipments, while double and triple corrugated cardboard is best suited for fragile or heavy products, for long trips and for export.

- Add foam profiles or cardboard corners to preserve the corners and edges of frames, furniture, etc. Any impact on these types of products can damage them;

- Close the package well, for example with tape. RAJA has a variety of different types of tape in its assortment, such as PP tape, paper tape, reinforced tape, coloured packing tape, or low-noise tape. We also recommend you to consider printed packing tape to showcase your brand on the packing tape.

See RAJA’s range of tapes here.

- Use tension tape to make it difficult for your parcels to be opened unwantedly. This way, no one can see the contents or remove a product.

And last but not least:

- If the most important thing for you is to choose the most environmentally friendly option possible, remember that within the different types of parcel filling and protection, there are environmentally friendly products. These are specifically designed to minimise the environmental impact of packaging.

See RAJA’s range of eco-friendly packaging here.

Want advice on choosing the right packaging fill and protection for your products?

Please contact RAJA’s Customer Centre on phone +45 22 51 40 00 or post@rajapack.no, or via the chat at www.rajapack.no. Our team of packaging specialists will be happy to help you!