We at RAJA often get questions about packing tables – how do you create the optimal workstation and what are the benefits? Here is a guide with many questions and answers, so you can get the right guidance when choosing a packing table for your company.

Why use packing tables?

A packing station that is suitable for your products and employees is important for the well-being and efficiency of your warehouse. As well as saving time and money when the packing process is streamlined, ergonomics for employees are put at the forefront.

How to choose the right packing table?

Start from what the packing process looks like for your products: What materials and tools do you need to have easily accessible to work quickly and ergonomically? First, choose the size of your workbench (1.6 x 0.8 m is recommended as standard), then decide whether you need static or dynamic height. This gives you a starting point that can be built on with the desired accessories as needed.

RAJA’s range of packing tables and accessories

RAJA has a good selection of packing tables and accessories. RAJA’s own packing table is the most affordable option and has everything you need: a durable table, shelves for drawers and tools, hangers for rolls of filling material, and a cutting unit with an ergonomic handle. The packing station is easy to assemble, it is estimated that it only takes around 15 minutes to set up if you are two people.

The SYSTEM FLEX series from Hudig Rocholz is the absolute best option for a customisable and flexible station based on your needs. You can easily adjust the height of shelves, legs and accessories. The perforated design of the shelves makes it easy to hook on additional accessories such as shelves, dispensers, etc. (completely tool-free), as well as to move them if necessary. The complete packing table includes a table, uprights, metal shelves and strips. Alternatively, you can choose an electronic height-adjustable packing tablewhich, in addition to the table itself, also includes three columns and two perforated back walls. Then supplement with accessories as required.

Need help choosing a packing table? Do not hesitate to contact us at RAJA. Our packaging specialists are available by phone 22541000 or email post@rajapack.no.

What should a packing table be equipped with?

Equip your packing table with tools and packaging adapted to your products. The items you use most often should be easily accessible. The table below gives an overview of what it usually looks like for RAJA’s customers:

Bonus Tip: Sometimes it can be difficult to visualise what a particular tool or accessory for a packing table actually looks like. Hudig Rocholz has developed a virtual showroom where you can explore their packing tables and modules in 360°. You can also build your own packing table online in their packing station configurator (choose “System flex” as base). Of course, you can turn to us at RAJA if you need help customising your workstation.

How to install the packing table?

Once you have all the packaging and tools and accessories needed, it’s time to plan what your packing table will look like. This means giving each tool its optimal location. For packing to be done as quickly and efficiently as possible, the most commonly used materials must always be close by. To visualise this, we divide the workstation into three zones:

- Zone 1 – Centre: The center of the table should provide enough free space for the packing process. A free and spacious work surface is a must. Within horizontal reach is equipment that will be used regularly. These include tape, a label printer and smaller boxes where pens, stickers, scissors, etc. can be stored. A dispenser for protective materials (roll of kraft paper or bubble wrap) is also useful.

- Zone 2 – Top: If you look up, you’ll find all the “outer packaging” there. Boxes, bags, envelopes, etc. Shelves with dividers make it easy to separate the different formats and quickly retrieve them.

- Zone 3 – Below: It would be a shame not to use the space below Here you still have enough room for a large dispenser (for bubble wrap, for example). You can also place some larger format boxes there.

- Extra: do you handle a large amount of orders and parcels every day? Use a separate machine next to the packing table for protective material, such as kraft paper or bubble wrap. Don’t forget to place a rubbish bag near the packing table.

Why is ergonomics important?

If you invest in ergonomics, you will see many benefits: more satisfied employees, a more sustainable way of working, fewer sick days, higher safety in planning, and of course the most important: better health for your employees.

A poorly planned workplace can lead to musculoskeletal disorders. Think hunched shoulders, back or leg pain. Therefore, it is important to set up the packing table so that it is convenient to use correctly.

What does an ergonomic packing station look like?

The workplace should be designed to support proper ergonomics during the packing process. You need to take into account angles, so that it is as easy as possible to have good posture without thinking about it, and to avoid stretching unnecessarily. Here are four things to consider when adapting a packing station for ergonomics:

Proper working height

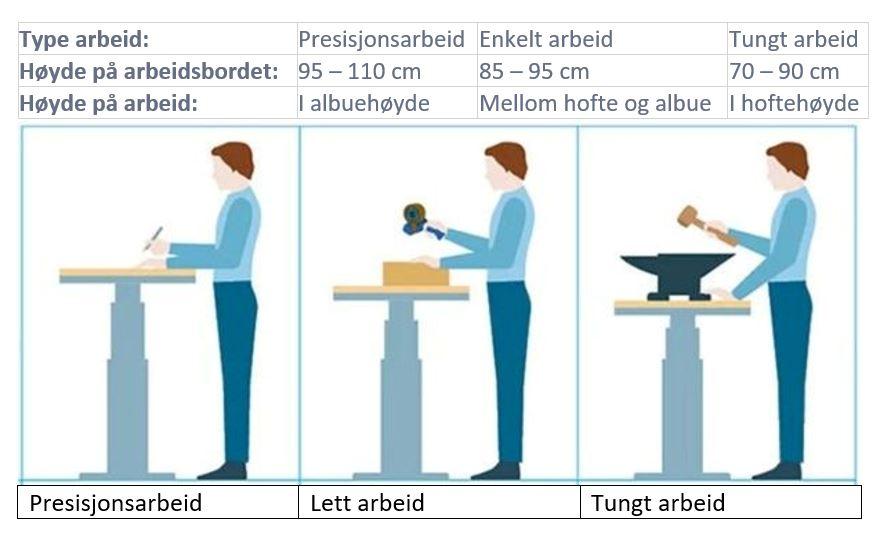

The right working height allows the worker to have good posture while performing the work. The right working height depends on the height of the worker and the nature of the work, see the table below. Packing is usually considered “light work”, which means a height of about 85 to 95 cm for the worktop. As a reference measure, use the height between hips and elbows. If you use a height-adjustable table, it is easy to adjust the height based on different work stages and employees.

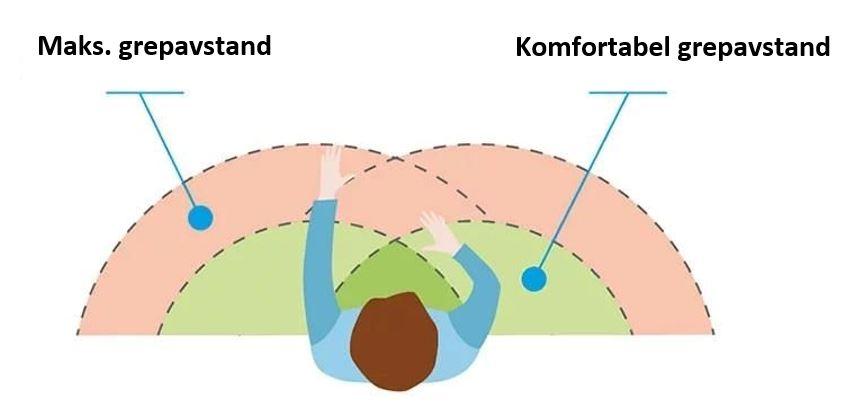

Horizontal grip distance

Making sure that the most commonly used materials and tools are easily accessible avoids the worker having to bend over and stretch their back, neck and arms unnecessarily. In the figure below, the “comfortable grip distance” corresponds to the location of the materials you use most often. This is roughly the distance between your wrist and elbow. Then there is the “maximum grip distance”. This corresponds to the distance between your wrist and shoulder (when you extend your arm). Here you can store materials that are not used very often.

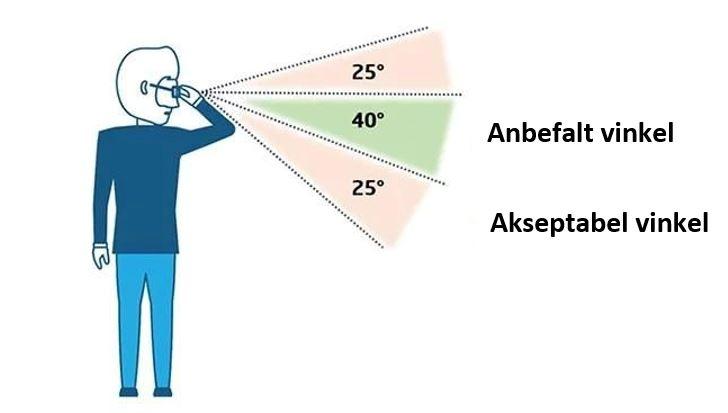

Angle of visual information

A sheet of packing instructions or a screen with order information can be a useful resource for those who want to pack their orders smoothly. Where is the best place to view this information? It depends on your field of vision and horizon line. It is best to view important or frequent information at a 40° angle. At a magnified angle of 25° above and below, you can place additional information. This way, the packer does not have to bend their neck too far and can reduce the risk of musculoskeletal disorders.

Vary your working position and encourage movement

There is no single optimal working position, the most important thing is variety. Alternate between standing, walking and sitting and take breaks several times during the day. Getting used to varying your posture throughout the day will reduce the risk of musculoskeletal disorders. Also, make sure that the chairs or stools used in offices and warehouses are ergonomic.

Need help choosing the right packing table?

RAJA are specialists in packaging and logistics. Feel free to contact us for tips and advice on packaging and ergonomics on phone 22514000 or post@rajapack.no.