Stretch film is much more than just plastic film, it’s an important tool in your warehouse. That’s because stretch film is the best solution for securing your pallets so that goods stay in place throughout transport.

Stretch film: essential for any warehouse

Stretch film is also used in RAJA’s own warehouse. A pallet is not fully packed without good, even layers of film. In addition to keeping our (and soon your) products in place, it also protects against dust, dirt and moisture.

It’s important that you apply the film correctly and that you use just the right amount. If you use too much stretch film, you’ll need more packaging, and you’ll have increased costs and unnecessary environmental impact. But if you use too little, your stretch film could tear and your goods could be damaged. Read on to learn how to use stretch film correctly.

How to choose the right stretch film?

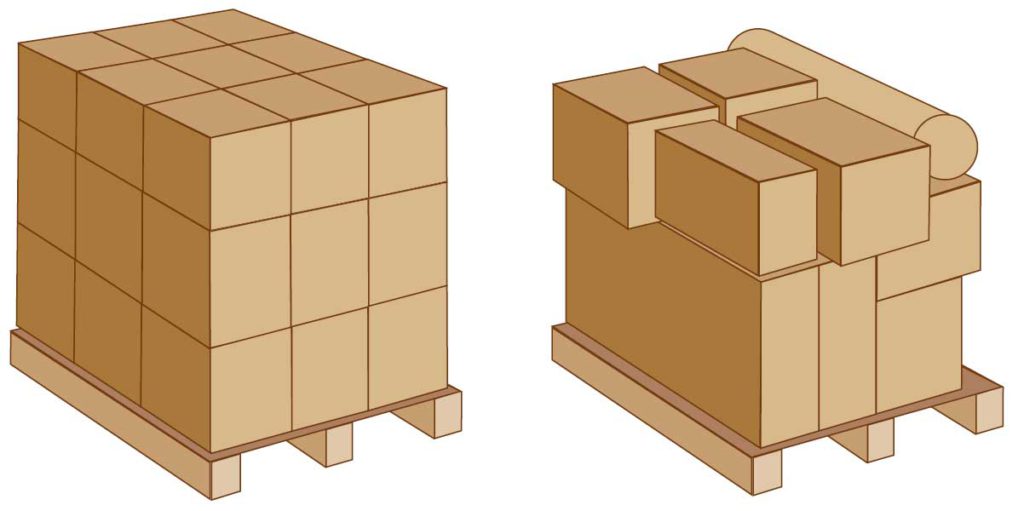

To choose the right stretch film, you need to take into account the weight and shape of the pallet. Both hand stretch film and pre-stretched film can be used for homogeneous pallets or for pallets with a slightly more irregular shape, but there are important differences.

The shape of your pallet determines which stretch film you should choose.

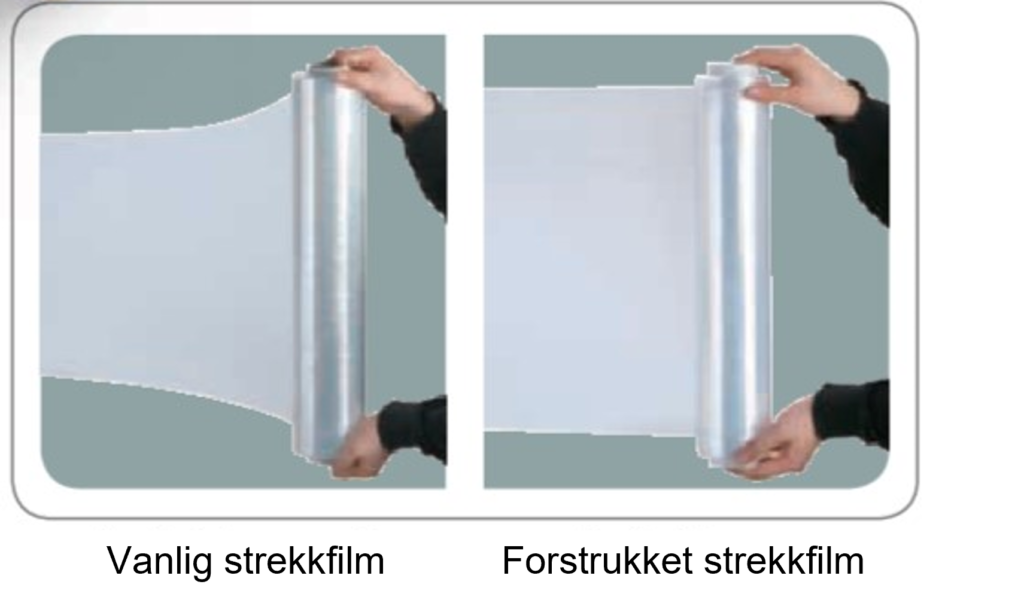

Hand stretch film is recommended for most palletising needs. It is a strong, elastic film that easily tightens around the goods and secures the load during transport. The adhesive is only on one side, and the film also has a smooth peel. Hand stretch film is also available in an environmentally friendly variant made from 80% recycled material.

Stretch film is mainly recommended for heavily loaded pallets. The film is inelastic and lightweight and retains its shape after palletising. The fact that it is stretch film means that it is applied very easily and that you save resources compared to stretch film that is not stretch film. Stretch film that is stretch film means that you produce half as much waste as with normal stretch film.

What thickness of stretch film should you choose?

As mentioned earlier, the weight of the pallet is a decisive factor when choosing stretch film. The heavier the load, the thicker the stretch film needs to be. The thickness of the plastic film is expressed in micrometres (1/1000 mm), also called my.

| Pall weights | Film thickness |

| 0-500 kg | Up to 17 my |

| From 500-700 kg | 20-23 my |

| From 700-800 kg | 23-30 my |

You can save both money and the environment by using thinner stretch film than before. The standard thickness of stretch film has previously been 23 my, but now many can go as low as 5 my. Especially in 2021 when the raw material price of plastic is particularly high, there may be much to be gained from going down in thickness. Read about RAJA’s stretch film types here.

Ministerial films for smaller packages

The standard size for stretch film rolls is 45 – 50 centimetres wide, but did you know that there are also so-called mini stretch films? These rolls are as small as 10 – 12 cm wide, perfect for those who need to wrap smaller and lighter packages, or perhaps pack together long products such as tubes. Stretch films are used in conjunction with our own stretch film dispensers.

Ministerial films – suitable for e.g. wrapping of light packages and bundling of long products

Transparent or coloured stretch film?

The most common choice is transparent stretch film, but did you know that you can also use stretch film to give personality or organise by colour coding? RAJA’s black stretch film is non-transparent and gives really good personality, this guarantees that the contents of your pallet are confidential. If your products are not visible, the risk of theft is reduced. Our coloured stretch film is also available in blue or white – this ensures that your pallets are recognisable and the colours can be used to structure your stock.

Manual or automatic wrapping

There are two ways to apply stretch film: either manually with a hand stretch film dispenser or mechanically with a stretch film machine (note that you need machine stretch film if you use a machine). If you film more than 15 pallets per day, we recommend that you choose one of our wrapping machines.

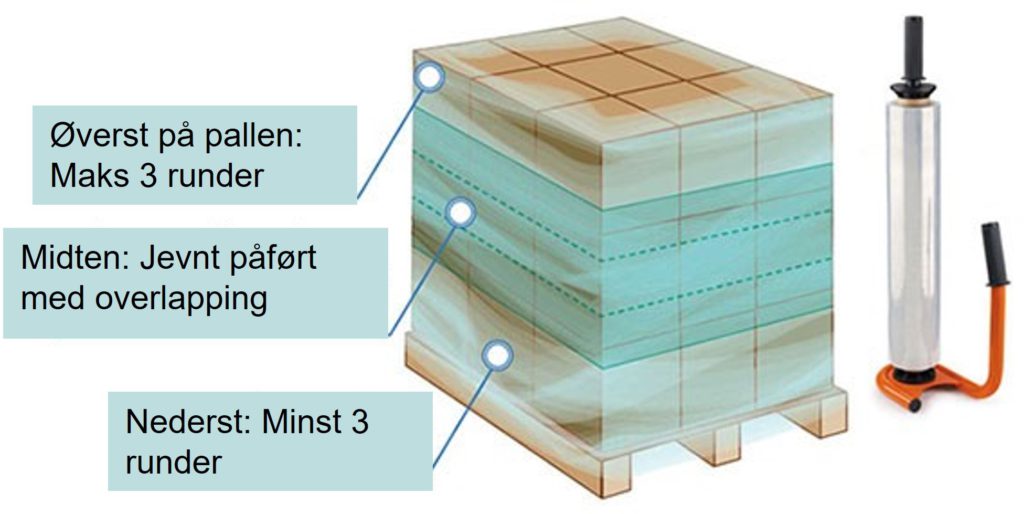

How to apply stretch film manually?

To apply the stretch film to your pallet: mount the roller on the dispenser, apply the sticky side of the stretch film to the load and roll around the pallet. For best effect, avoiding overuse of materials while applying enough to get enough protection: apply three layers of stretch film to the upper and lower part of the pallet, with a evenly applied overlap in the middle part of approximately 10-20 centimetres.

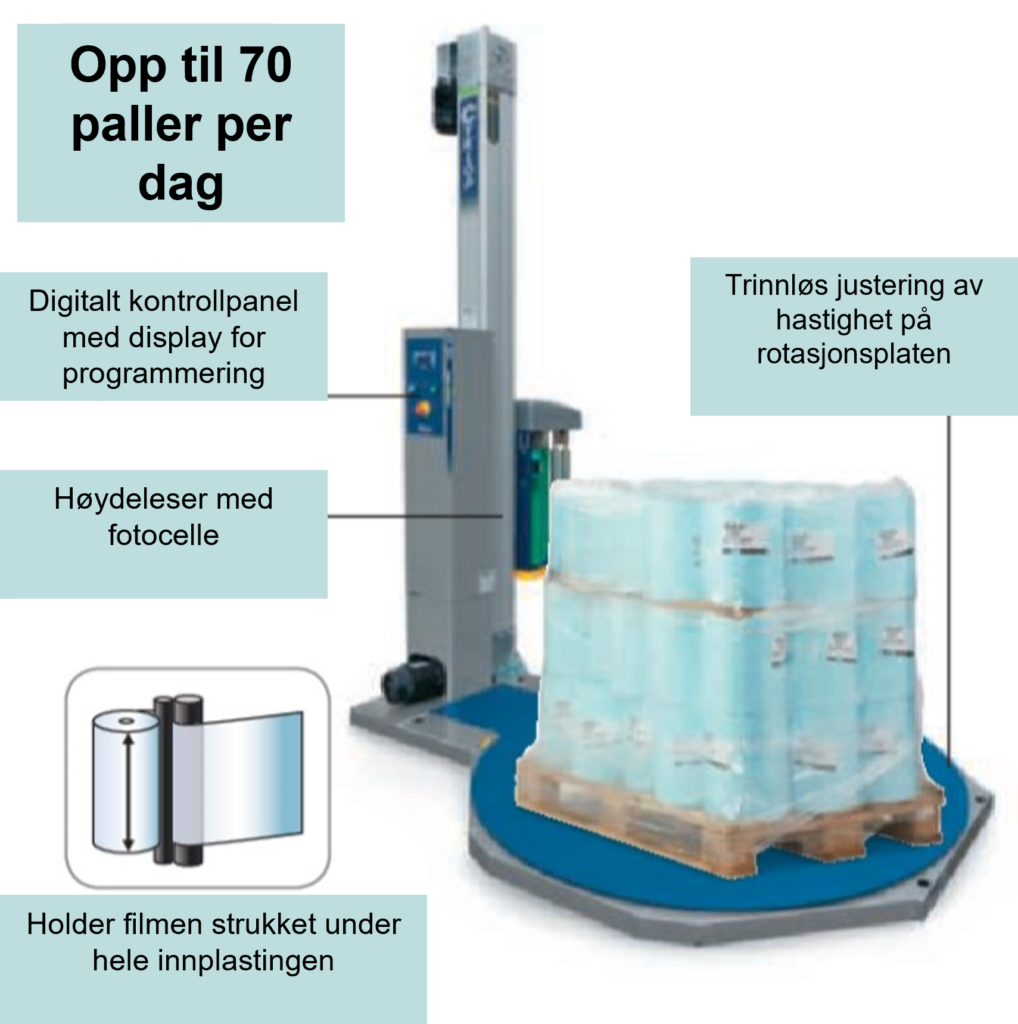

How to choose the right stretch film machine

If you are filming more than 15 pallets per day, a stretch film machine is recommended. RAJA has stretch film machines in several designs, so you can find one that meets your needs. Stretch film machines with mechanical brakes are well suited for irregular and curved pallets, and can handle up to 25 pallets in a day. Choose a stretch film machine with motorized pre-stretching, which can film up to 50 pallets per day if you have large pallets with irregular shapes in reduced spaces. Our most powerful stretch film machine also has a digital control panel and can film as many as 70 pallets in a day.

Why invest in a stretch wrapper?

- Economical: you reduce your consumption of stretch film

- Efficient: you increase productivity

- Better results: your pallets are better protected

- Easier: you can wrap your pallets without physical effort

Need help choosing the right stretch film?

RAJA are experts in everything packaging – from esker and packaging tape to stretch films and packaging machines. Please contact us for tips and advice on which stretch film to choose, or which stretch film machine is best suited to your needs. You can reach us by phone 22 51 40 00, post@rajapack.no or via chat at www.rajapack.no.