Wrapping film is not just another piece of plastic. It is indispensable in every warehouse! Why? Wrapping film or stretch film is the most durable and economical material for securing your pallet loads securely. This will keep your products or boxes nicely in place during bumpy transport or long-term storage.

1. Wrapping film: indispensable in every warehouse

Here at RAJA, we absolutely cannot live without it either. A pallet is incomplete without a solid layer of wrapping film. After all, it protects our (and therefore your future) products from dust, dirt and moisture and ensures that the pallet forms a solid whole. It is important to apply the film correctly. If you wrap too much, you will need more packaging material and thus increase your own costs. If you wrap too little, your film may tear and damage your goods. Read on and find out how to avoid this.

2. How do I choose the right film?

To choose the right wrapping film, you need to consider the shape and weight of your pallet. Of course, you don’t want the film to give way under the pressure of the pallet load. Make the right choice!

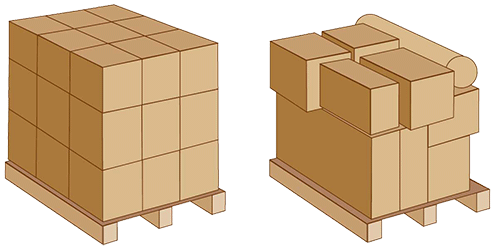

► For pallets with a homogeneous and/or slightly protruding load

| Cast CAST film .  |

. – The standard for average pallets. – Elastic in one direction (length). – Adhesive layer is on the inside. – Glossy and perfectly transparent. – Low-noise during unrolling. – Stretchable up to 120% to 300%, depending on version. |

| Pre-stretched film .

|

. – More economical and faster to use. – Enormous tensile strength: pre-stretched film is already optimally stretched. The advantage of this is that you need to use less force to apply the film. – Goods are not deformed by pressure. – Up to 250% stretch = 1 metre becomes 3.5 metres. |

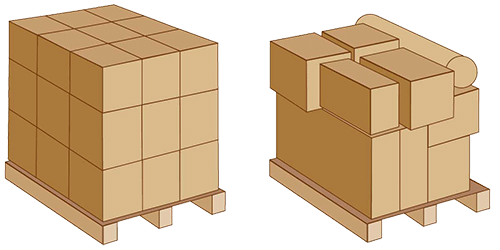

► For pallets with heterogeneous and/or strongly protruding loads

| Blown film .  |

. – Very strong: best resistance to tearing. – Suitable at freezing temperatures. – Elastic in both directions (length and width). –Adhesive layer is added separately, making the film somewhat matt. – Adhesive film is often on the outside. – Up to 150% stretch = 1 metre becomes 2.5 metres. |

As mentioned, the weight of your pallet is also a determining factor. The heavier the load, the thicker the wrapping film should be. By the way, the thickness of the film is expressed in microns (1/1000 mm).

| Weight of the pallet | Thickness of the film |

| ≤ 500 kg | ≤ 17 microns |

| ≤ 700 kg | Between 20 and 23 microns |

| ≥ 800 kg | Between 23 and 30 microns |

3. Manual or machine application of wrapping film?

Wrapping film is made of low-density polyethylene; a very flexible and lightweight material. There are two ways to apply the film: manually with an unwinder or mechanically with a wrapping machine. If you need to wrap more than 15 pallets per day, we recommend choosing one of our pallet wrappers. Not every wrapping film can be used with a machine. Always check this carefully before purchasing stretch film.

► Manual application

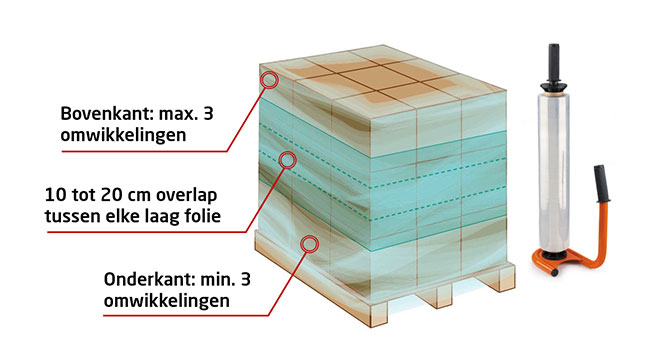

To do this, place the roll of stretch film in the unwinder and make sure that the sticky side of the film sticks to your load (otherwise your pallets will stick together). Cover the top and bottom of your pallet with at least 3 layers of wrapping film. Finally, make sure the layers of stretch film overlap by at least 20 cm. On average, you will have to count on around 18 wrappings per pallet load.

► Applying by machine

With a machine, it goes without saying that almost all the work is done for you. For every packaging volume, there is a wrapping machine to suit. Download our guide to wrapping machines here so that you know which pallet wrapper to choose. This will save you a lot of time and therefore money.

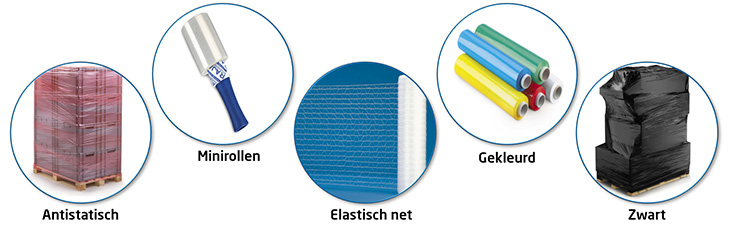

]4. Wrapping film: from A(ntistatic) to Z(wart)

Transparent wrapping films on 50-cm rolls are the most common. Almost everyone who works in a warehouse is familiar with them. But there are, of course, a few special cases:

► Anti-static film: this stretch film is suitable for wrapping electronic products.

► Mini rolls of wrapping film: these rolls are between 9 and 12 cm wide. They are ideal for wrapping small packages and packing light shipments.

Elastic pallet net: stacked pallets with products that are susceptible to condensation damage are best wrapped with a flexible flexi net. This sturdy net has large meshes. This allows your products to breathe sufficiently and keeps them dry.

Coloured wrapping film: wrapping film in blue, red, yellow, green and white ensures that your products can be recognised at a glance. Use this film to bring more structure to your warehouse.

► Black opaque wrapping film: with this stretch film, the confidentiality of the contents of your pallet is always guaranteed. Your products are not visible and therefore less tempting to thieves.

- Choose cast film or pre-stretched film in the case of a homogeneous load.

- Choose blown film in case of a heterogeneous load.

- Colour your pallet to identify its contents faster, or protect them from theft with black, opaque film.

- Do you wrap more than 15 pallets per day? Then work faster and more economically thanks to a wrapping machine. Download our e-book here and see which machine best suits your needs