0201, 0300, 0340 – does that tell you anything? Or do 0712 and 0713 look suspiciously like “007”? No, these numbers are not code words from the latest James Bond film. And “FEFCO” is also not an abbreviation of an ominous secret language. Rather, it has everything to do with the serious subject of cardboard boxes. FEFCO codes bring order and structure to the vast and sometimes rather confusing market of boxes. How exactly do these FEFCO codes work? Read on and unravel every secret.

1. What does FEFCO mean?

The acronym FEFCO stands for Fédération Européennedes Fabricantsde Carton Ondulé – an association of European corrugated board manufacturers. Based in Brussels, this non-profit organisation deals with all issues relevant to the manufacture of cardboard packaging. One of its many achievements is the development and updating of the FEFCO codes. This international coding makes it a lot easier for you to quickly find the right box. How exactly does it work? We explain it to you in full below.

90 million tonnes - that's the total amount of paper and cardboard produced by European manufacturers in 2021. Almost half of this ends up as packaging material, think boxes. For almost every product on the market, there are boxes developed to package it optimally. So that means you can choose from many hundreds of different sizes. Without cardboard, our lives would probably look very different.

2. What are the FEFCO codes?

As diverse as cardboard is, so are the design possibilities for cardboard boxes and packaging. Anyone who has assembled a box before will have noticed how many perforations and folds there are. While this all has a practical reason, it also complicates communication between users, retailers and manufacturers. Therefore, in the 1960s FEFCO decided to standardise the designations for cardboard boxes using a simple numerical code. These FEFCO codes can now be found all over the world. Thanks to the FEFCO code, everyone in every country therefore speaks the same ‘language’ and misunderstandings regarding size, shape or design are avoided.

FEFCO has also standardised the technical drawings for folding boxes. This makes it clear at a glance where to fold inwards and outwards, where to cut, crease or glue. And always with a clear goal in mind: “FEFCO wants to replace cumbersome definitions of corrugated boxes and packaging with simple, internationally recognised symbols that are universally understood, regardless of language or other barriers.“

3. How is a FEFCO code composed?

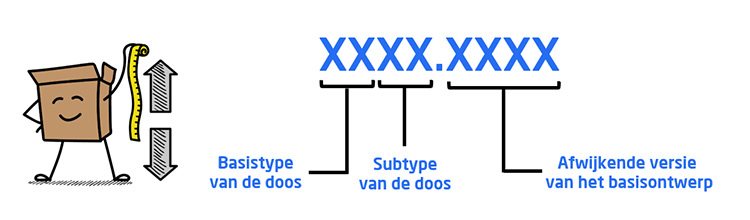

The FEFCO code allows all solid or corrugated board boxes to be divided into different basic types. The FEFCO code number consists of four digits. For example, 0201 is the code for a classic folding box made of corrugated cardboard (one of the most common variants in the Netherlands, by the way). The code includes information not only about the shape, but also about the way you close the box. For example, box 0712 is one with flaps while variant 0713 is one with a lid.

The basic four-digit code can still be supplemented by up to four additional digits. These additional digits then indicate a different version of the basic design. For example, the code 0229.1 was added in 2022. That last ‘1’ then indicates a new deviating variant of the basic design 0229.

The two digits at the beginning of the code always indicate the basic box type. The FEFCO catalogue is divided into the following nine basic types:

| Base type | Properties |

01 – Rolls and sheets |

. – Made from long rolls of corrugated cardboard. – Starting form for all other forms in the FEFCO catalogue. – Example: folded cardboard or intermediate sheets. |

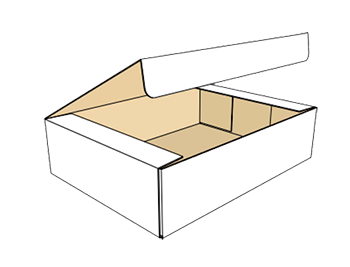

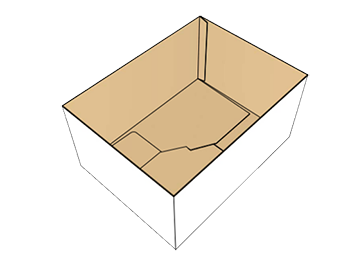

02 – Folding boxes |

. – Made from a single piece of corrugated cardboard. – The ends are fastened together with glue or staples. – To be closed via flaps. – Supplied flat to save space in storage. – Example: folding box made of double corrugated cardboard . |

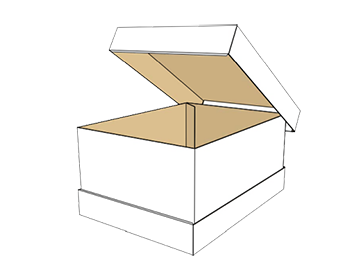

03 – Lidded boxes |

. – Consists of at least two components. – Both parts can be set up separately and should be placed on top of each other after filling the box. – Example: extendable lid box. |

04 – Wrapping boxes and trays |

. – Made in one piece. – Parts are placed together before closing via slots or flaps on the sides and therefore do not need to be glued or stapled. – Example: brown postal box. |

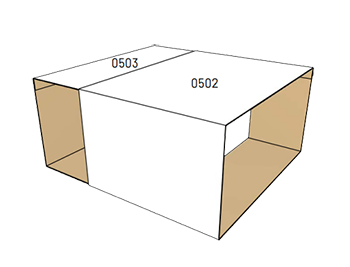

05 – Sliding boxes |

. – Consists of several sleeves that slide into each other (possibly in different directions). – Are glued or stapled during production. – Example: sliding box with foam filling. |

06 – Moulded boxes |

. – Consists of several individual pieces joined together during the production process. – The fixed construction ensures particularly high stability. |

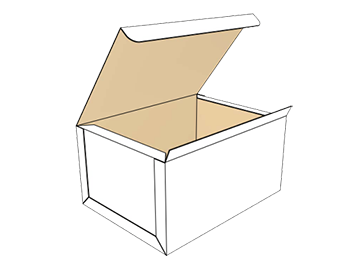

07 – Ready-made boxes |

. – Made from a single piece. – Set up in seconds: ideal for quick assembly of packages. – Example: boxes with automatic bottom. |

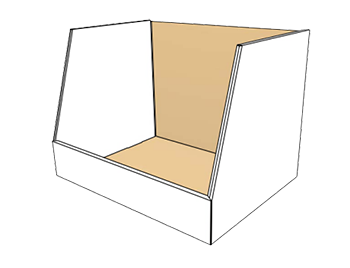

08 – Retail and e-commerce |

. – Offers typical formats and styles used, for example, for displays in shops or for storage and shipping via online shops. – Example: cardboard warehouse box. |

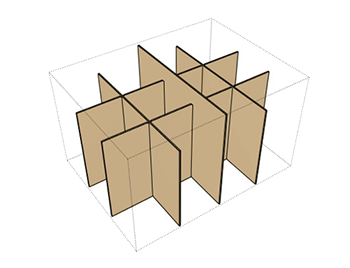

09 – Interior finishes |

. – Boxes, bases and dividers. – Serves to protect the packaged goods: the contents cannot slip or be crushed. – Example: bottle packaging with vertical compartments. |

4. What are the standardised dimensions for packaging?

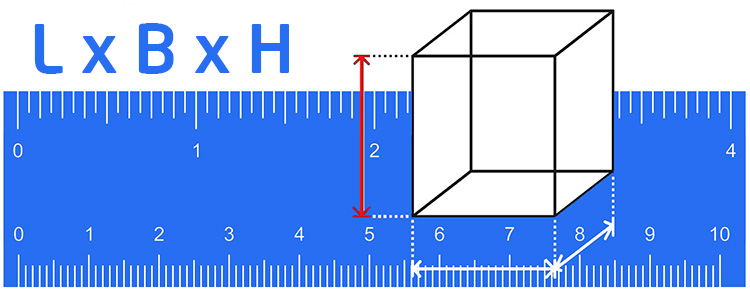

Box dimensions always consist of three size designations: length, width and height. With an almost endless range of box sizes, it is not always immediately clear which number indicates length, width or height. Good news for you: this is standardised in a fixed order. And that order goes like this: L x W x H.

- Length (L) = the longest side of the open box.

- Width (B) = the shortest side of the open box.

- Height (H) = the inside edge between the bottom of the box and the opening.

Standard choose me mainly for the inside dimensions of a box. You can read more about that below. By the way, the unit of measurement of the dimensions is also uniform. It is given in millimetres. In this way, errors in measurements can be avoided as much as possible. Exceptionally, however, box dimensions may be given in inches (= 2.54 cm) or cm (= 0.393701 inch).

5. Inner size or outer size of a box?

What is the best way to indicate the dimensions of a cardboard box? Should you refer to the internal or external dimensions of the box? Because the difference between these two sizes can vary considerably depending on the quality of the cardboard (single corrugated, double corrugated or triple corrugated). Here are some handy guidelines.

-

The inner size is the standard indication for box dimensions. This allows you to perfectly determine the size of the items to be packed in the box. It is important to choose the box a few millimetres larger than the dimensions of the goods to be packed. On the one hand because there may be production-related deviations in the cardboard boxes (e.g. in the material thickness of the cardboard) and on the other hand because this facilitates packing and later removal of the goods. For particularly sensitive products, padding material may also be required to optimally protect the contents.

-

The outer size of a box is important when you need to properly estimate the available space in your warehouse or a truck. If you stack boxes on a pallet, this is obviously an extra point of attention. The outer dimensions are calculated by measuring the dimensions of the sides of the closed box and adding a material tolerance of 5 mm.

6. How is a bespoke box created?

Do you usually pack 1 specific product? Then a custom-made box can be the perfect solution to save on packaging material. The better the box fits around your product, the less padding is needed inside. The small additional cost of a custom-made box will therefore be more than offset by your other packaging costs. Everything starts with developing a digital design for such a personalised box. Once this design is approved by the customer, we order the necessary die-cutting tools for production and – if printing is required – the corresponding printing plates.

During production, the individual layers of corrugated cardboard are brought together and glued, then punched out and printed. There are various options for printing on that finished board, depending on what is needed. Offset printing is particularly suitable for gift boxes or displays. The motif is printed on a carrier film and then applied to the corrugated board.

In screen printing, the corresponding image is applied directly to the substrate to be designed using stencils. Due to the slightly longer production time, this method is mainly recommended for designing smaller quantities. Flexo printing is the third option and the most commonly used printing method for corrugated products. For example, it is often used to apply logos directly to the packaging.

]