Pulp paper is enormously versatile, easily recyclable and gives your packaging a sustainable look. Below, we list all the benefits for your business. To complete the picture, we also show you all the machines you can use to make your own pulp paper quickly and inexpensively. For more information, download RAJA’s free e-book on packaging machines here.

1. Refill paper, something for you?

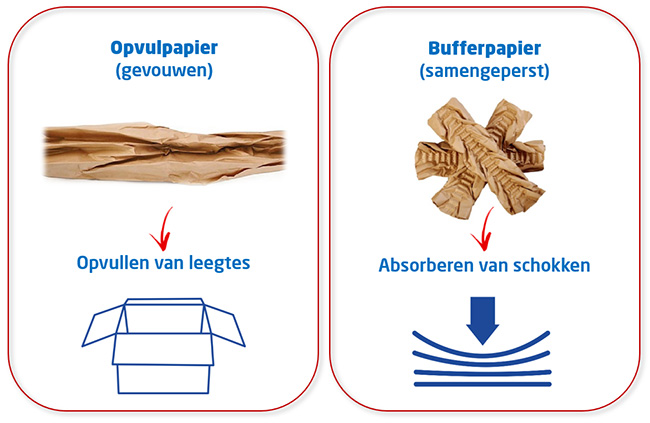

Corrugated or not, brown or white, crepe paper, kraft paper… Within the family of padding paper, you have a huge choice. Paper padding is generally used for two things:

► Filling empty spaces in a box. This makes your products more firmly secured. To do this, it is best to use single-ply folded padding paper.

►

Absorb shocks; ideal for shipping fragile products. For this, it is best to use multilayer compressed buffer paper.

2. The five advantages of pulp paper

![]() Paper quickly adds value to your packaging: it looks natural and neat.

Paper quickly adds value to your packaging: it looks natural and neat.

![]() Due to its ‘natural’ nature, paper is easier to recycle. You can simply dispose of it with the waste paper. Moreover, almost all RAJA’s filling paper is made of recycled material.

Due to its ‘natural’ nature, paper is easier to recycle. You can simply dispose of it with the waste paper. Moreover, almost all RAJA’s filling paper is made of recycled material.

![]() Recovery paper is always antistatic and generally free of acids and chlorine. This makes it the best protection when packing printed documents or photos. By the way, there is also corrosion-resistant paper. Very handy if you need to package metal parts.

Recovery paper is always antistatic and generally free of acids and chlorine. This makes it the best protection when packing printed documents or photos. By the way, there is also corrosion-resistant paper. Very handy if you need to package metal parts.

![]() Thanks to its versatility, void fill paper adapts perfectly to your products, small or large. In other words, it is easy to manipulate.

Thanks to its versatility, void fill paper adapts perfectly to your products, small or large. In other words, it is easy to manipulate.

![]() Paper is safe because it can cover even the sharpest objects without losing strength. However, air cushions can be torn and deflated by sharp objects, making them ineffective.

Paper is safe because it can cover even the sharpest objects without losing strength. However, air cushions can be torn and deflated by sharp objects, making them ineffective.

3. Get more benefits from pulp paper with a machine

]► Save time: with a packaging machine, you make your own pulp paper, whenever you want, without depending on a supplier. You don’t have to compromise on time in the process: a packaging machine makes up to 84 m of pulp paper per minute. Ideal for further boosting your productivity.

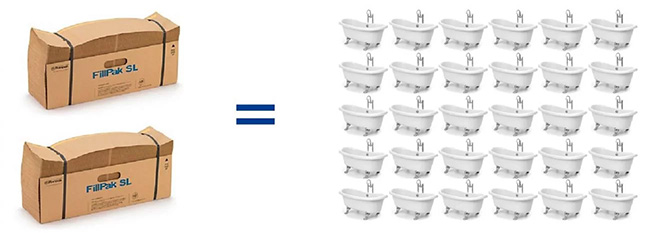

► Save space: a pack of paper for a packaging machine is very compact. You can fill up to 30 tubs full of filling paper with two packs. This leaves much more space free in your warehouse, e.g. for storing additional products.

Many packaging machines can be easily rented, making a large investment unnecessary. Making your own packaging equipment is the best way to reduce your daily packaging costs. Call 0800-224 24 24 for a free trial at RAJA.

Many packaging machines can be easily rented, making a large investment unnecessary. Making your own packaging equipment is the best way to reduce your daily packaging costs. Call 0800-224 24 24 for a free trial at RAJA.

4. Which packaging machine suits your business?

For an answer to this question, it is best to take a look at the overview below. You’ll find Ranpak’s most popular paper packaging machines there.

Packaging machine |

Consumption |

Features |

| FillPak® M |

– Up to 100 packs/day | – For the fill Of voids. – Produces filler paper. |

| FillPak | – 1000 to 2500 packets/day | – For the fill Of voids. – Produces void fill paper. |

| PadPak | – 100 to 1500 packets/day | – For the absorb Of shocks. – Produces buffer paper. |

| WrapPak® Protector | – 100 to 1000 packets/day | – For the fill of voids and the absorb of shocks. – Produces buffer paper. |

Manual paper dispenser FillPak® M ► Fills empty spaces

This manual system fits any packing table. You pull the pre-cut paper through the funnel of the FillPak® M in one smooth motion. The result is perfectly folded filler paper with which you fill the voids in a box and secure your products. It is also height-adjustable, very light (4 kg) and easy to install on a packing table.

Machines FillPak ► Fills empty spaces

These systems automatically produce up to 84 m of cushioning paper per minute (in the form of single-layer folded paper). One pallet of paper from this machine equals 72 m³ of cushioning, or 480 filled bathtubs! With the foot pedal, you easily control the production speed yourself. As a result, your hands are always free which will make your work considerably easier.

Machines PadPak® ► Absorbs shocks

These systems from Ranpak differ a little from what we have looked at so far: namely, they do not produce ‘folded’ but just ‘compressed’ buffer paper. This paper is reminiscent of a harmonica. This shape allows it to absorb shocks much better and keeps your (fragile) products extra well protected. The more layers of paper the buffer pad contains, the better the protection, by the way. Within the family of PadPak® machines, you have a choice of these 4 models at RAJA:

| PadPak Junior | PadPak Senior | PadPak® CC Compact Cushioning |

LC Light Cushioning |

|

|

. |

|

| < 100 packs/day | < 1000 packs/day | < 500 packs/day | < 1500 parcels/day |

| 18 m paper/min. | 21 m paper/min. | 36 m paper/min. | 72 m paper/min. |

| Paper: 2 layers For fragile items |

Paper: 2 / 3 layers For heavy or bulk items |

Paper: 1 / 2 layers For small items |

Paper: 1 layer For light or fragile items |

| The most mobile | The most versatile | The most compact | The fastest |

Machine WrapPak® Protector ► Fills empty spaces as well as absorbing shocks

Within the family of paper cushion machines, this is undoubtedly the most deployable solution. The Wrappak® Protector was designed to meet the two most important packaging needs: filling empty spaces in a box and absorbing shocks. To do this, it produces buffer paper in a new, unique shape. See the numerous applications and advantages of the Wrappak® Protector in the video below.

]5. Also take a look at these variants

Cardboard perforator HSM® ► Recycle your used cardboard

Are there piles of used cardboard lying around in your warehouse every day? Then give them a second life and turn them into filling paper using a cardboard perforator. Even small metal parts such as staples are no problem. Among RAJA’s cardboard perforators, you have a choice of two models: a tabletop model (for single corrugated cardboard) or a model on wheels (for single, double, or triple corrugated cardboard). Read our article on the benefits and operation of a cardboard perforator here.

Geami WrapPak® ► The most original way to pack

With this device, you combine two packaging materials: silk paper and kraft paper. The soft silk paper provides a colourful finish and protects against scratches. The kraft paper on its side protects your product from shocks. Due to its unique shape (with a honeycomb pattern), the kraft paper hooks together smoothly, making tape even superfluous. Both paper types roll out of the system simultaneously and ensure super-fast packaging. Want to know more? Then take a look at this article about the Geami WrapPak®.