In our previous article, we revealed the advantages of paper padding. Now that paper no longer holds any secrets for us, it is time to take a closer look at its partner: air foil. Like paper , airfoil is a hugely versatile material for packaging and protecting your products . It is strong, super-light and recyclable. In this article, we will also show you how a packaging machine can make your logistics process lighter and more cost-effective.

1. Airfoil, something for you?

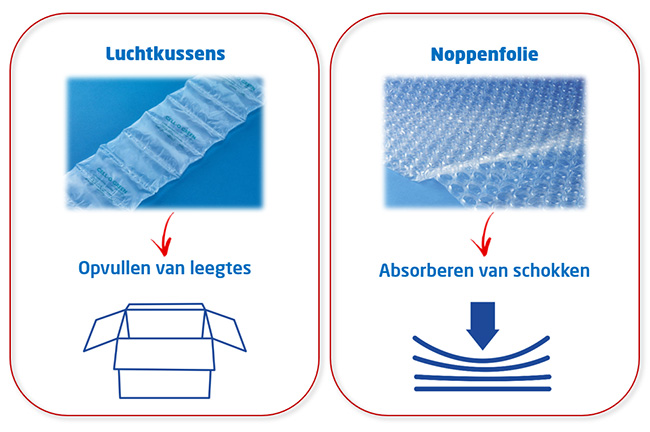

Air film is the basis for two types of plastic packaging material: bubble wrap and air cushions. This type of packaging material is ideal to use for the…

► Filling empty spaces in a box. Your products remain highly visible while being firmly secured. Air cushions are usually used for this purpose.

► Absorb shocks; recommended for shipping fragile products, among others. It is best to use bubble wrap for this purpose. You can easily wrap these around your product, for example.

2. The six advantages of plastic air foil

![]() Air film is made of polyethylene (PE) or polypropylene (PP), making it incredibly strong. Compared to paper, it therefore lasts longer and can be reused more often.

Air film is made of polyethylene (PE) or polypropylene (PP), making it incredibly strong. Compared to paper, it therefore lasts longer and can be reused more often.

![]() PE and PP are good recyclable raw materials. The prerequisite is that the plastic is sorted and collected correctly.

PE and PP are good recyclable raw materials. The prerequisite is that the plastic is sorted and collected correctly.

![]() Air film is very light because it consists mainly of… air. And as you have long known: the lighter your parcel, the lower your shipping costs.

Air film is very light because it consists mainly of… air. And as you have long known: the lighter your parcel, the lower your shipping costs.

![]() It does not entail any dust. So your workplace and parcels stay perfectly clean.

It does not entail any dust. So your workplace and parcels stay perfectly clean.

![]() The transparent film keeps your products visible while protecting them.

The transparent film keeps your products visible while protecting them.

![]() Air film is both waterproof and airtight. There are also variants that provide extra protection. Think of antistatic film (for electronic products) or film with an aluminium layer (for temperature-sensitive products).

Air film is both waterproof and airtight. There are also variants that provide extra protection. Think of antistatic film (for electronic products) or film with an aluminium layer (for temperature-sensitive products).

3. Get more benefits from air film with a machine

]► Save time: a packaging machine can produce up to 30 m of air film per minute. This is not only fast but also gives you a lot of freedom: your employee simply makes bubble wrap or air cushions whenever he wants, leaving his hands free for other tasks. You are also less dependent on a supplier.

► Save space: with a packaging machine, you save a lot of storage space in a simple way. For example: with 7 small rolls of plastic film, you can make filling material to fill an entire truck (this is 12.9 m³ of air cushions). So you create a lot more available space in your warehouse.

Many packaging machines you can easily rent, making a large investment unnecessary. Making your own packaging equipment is the best way to reduce your daily packaging costs. Call 0800-224 24 24 for a free trial at RAJA.

Many packaging machines you can easily rent, making a large investment unnecessary. Making your own packaging equipment is the best way to reduce your daily packaging costs. Call 0800-224 24 24 for a free trial at RAJA.

4. Which packaging machine suits your business?

Choose the machine below that best suits your needs. Filling, protecting, wrapping or all at the same time? The choice is yours!

Packaging machine |

Consumption |

Features |

| Air pump Rapid Fill™ |

– Up to 100 packs/day | – For the fill of voids. – Produces air cushions. |

| AirFirst® |

– Up to 100 packs/day | – For the fill Of voids. – Produces air cushions. |

| Fill Air® Rocket | – 500 to 2000 packs/day | – For the fill Of voids. – Produces air cushions. |

| New Air® | – 500 to 1500 packets/day | – For the absorb Of shocks. – Produces bubble wrap. |

| RAJA® | – 300 to 1500 packets/day | – For the fill of voids or the absorb of shocks. – Produces air cushions as well as bubble wrap. |

Air Pump Rapid Fill™ ► Fills empty spaces

Air Pump Rapid Fill™ ► Fills empty spaces

This air pump is ideal for filling voids in packaging. It is often used by start-ups that do not yet need regular filling equipment. It is light and compact, making it easy to move around. Thanks to its flexible tube, the Rapid Fill’s bags are always easy to fill.

Machine AirFirst® ► Fills empty spaces

Machine AirFirst® ► Fills empty spaces

The AirFirst® is the most compact machine on our list and is a great alternative to the air pump above. It creates air cushions fully automatically, allowing you to easily fill voids in a box. In addition, you can use the inflated film as a buffer to separate products. It is ideal as an entry-level model for small consumers.

Machine Fill Air® Rocket ► Fills empty spaces

Machine Fill Air® Rocket ► Fills empty spaces

This system is ideal when you process between 500 and 2,000 packs per day. It makes up to 30m air cushions per minute so you will never run out quickly. The film for this machine is available in 6 variants. That equals 6 sizes of cushions. You then use these air cushions to fill the empty space in your box.

Machine New Air® ► Absorbs shocks

Machine New Air® ► Absorbs shocks

With the New Air machine, you can easily process around 500 to 1,500 packages per day. Instead of air cushions, this machine mainly specialises in making bubble wrap. As we mentioned earlier, bubble wrap is used for wrapping products and absorbing shocks. Choose either fully transparent film, or black translucent film (which was 15% recycled).

Machine RAJA® ► Fills empty spaces AND absorbs shocks

Machine RAJA® ► Fills empty spaces AND absorbs shocks

We conclude our comparison with the most versatile of all machines. The RAJA machine can produce both air cushions and bubble film and can handle up to 1,500 parcels/day. Many unique film types have also been developed for the RAJA machine. For example, try a film made of recycled material. Or go to work with film made of potato starch.