Warehouse shelving can be found in a multitude of designs and sizes. So how do you choose the right type with certainty? To help you with this, RAJA’s logistics experts list all the points of interest. Go through this guide and choose a storage rack that suits your needs perfectly. From the smallest trays to the largest pallets, they all get a perfect storage place. Here’s another look at the main components of average racking:

► Step 1: How much load should your storage rack be able to handle?

When choosing a rack, you should first look at the weight of your load. That determines how robust your warehouse rack needs to be. Linked to that, you need to decide where you want to place the warehouse rack. Should it be in an office, in a retail corridor or in a large warehouse? We distinguish between three types of racking:

- Storage racks (up to ± 200 kg load capacity): This is the simplest type of rack, composed of uprights and (tube) shelves. The space between the shelves is at the ideal height for binders and file folders.

- Shelving units (up to ± 500 kg load capacity): A shelf rack is based on the same principle as a storage rack, but is often equipped with accessories that provide more stability or load-bearing capacity. Think of a tensioning cross cable mounted at the back or side, or shelves welded in one piece. A number of variants are also galvanised, making them suitable for outdoor use.

- Warehouse shelving and pallet racks (up to ± 3000 kg load): the uprights of these racks are reinforced with horizontal or diagonal beams. This makes it even stronger. Your load rests on support beams (one at the back and one at the front), on which another shelf may be placed (for smaller goods). These racks are usually anchored into the floor for safe use.

for office, archive or stockroom. |

For workshop, shop, (small) warehouse, etc. |

and pallet racking for workshop or large warehouse. |

| Load capacity up to ± 200 kg per shelf |

Load capacity up to ± 500 kg per shelf |

Load capacity up to ± 3000 kg per shelf |

| For storage of boxes, file folders files, etc. |

For storage of small goods or storage boxes. |

For storing heavy or bulky goods or pallets. |

|

|

|

- If your racking has to support at least 200 kg per level, provide a concrete base.

- Always store your heaviest goods at the bottom.

- Add cross ropes or wire rods and give your rack more stability.

- In the Netherlands, pallet racking is required to have at least 2 floor anchors per anchoring plate (i.e. this is equivalent to 4 anchors per upright).

]

]

► Step 2: How to choose the right shelf?

A warehouse rack without shelves would just be an empty box, wouldn’t it? So in the second place, we are going to compare the different types of shelves. To make the right choice in this, you need to know well what kind of load you want to place in your warehouse shelving: bins, boxes, bulk goods, long products, pallets…? Moreover, remember that not every shelf is suitable for every storage rack. Therefore, check the technical sheet to see which shelf is compatible with your desired rack.

Before starting this comparison, we will make another important distinction. On the one hand, there are shelves that must be screwed or clicked into the frame of your rack. On the other hand, there are shelves that you place loose on top of a fixed tube shelf.

Choose the right covering for your magazine rack:

- Epoxy: a painted coating. Ideal for indoor use or in an office.

- Galvanised: a coating that resists corrosion, impacts and scratches. Ideal for a damp or greasy working environment, in warehouses or outdoor use.

► Step 3: How do you put together a warehouse rack?

We have almost arrived at your ideal warehouse rack. You are left to choose from two types:

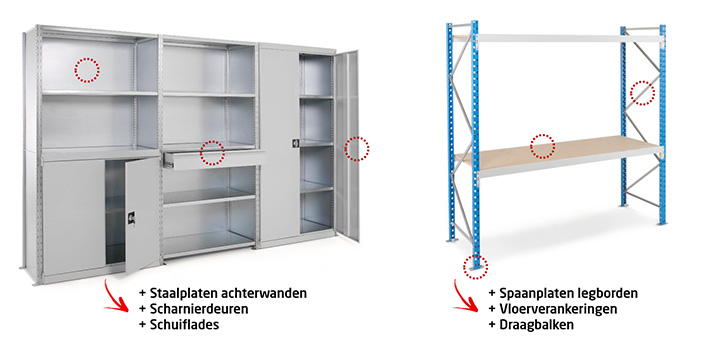

► One-piece warehouse shelving: this is a ready-made solution consisting of a basic element that can be easily supplemented in width by one or more attachments.

► Warehouse racks to assemble yourself: this type of rack has to be constructed entirely by yourself with various accessories to achieve a customised rack. For example, you can choose to integrate a tool wall, hinged doors or additional shelves. The choice is yours! You can simply place this type of rack alongside each other and keep expanding.

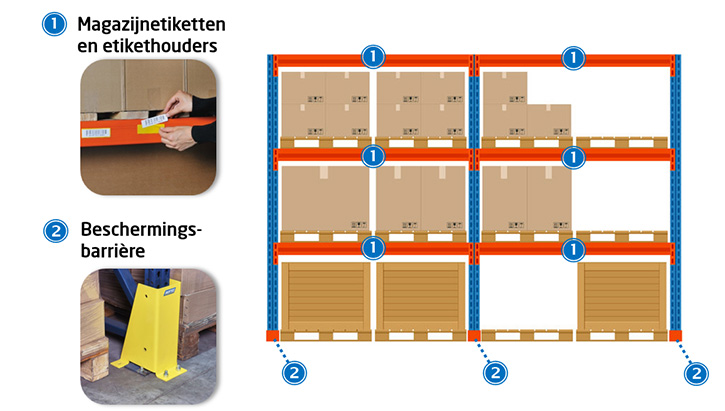

► Step 4: How do you protect and identify a rack?

]Passages between racks can sometimes be very narrow, which means that a collision with a forklift or transpallet cannot be ruled out. To best safeguard your warehouse rack – and especially the goods on it – we recommend installing steel protective barriers. Once anchored in the ground, such barriers can take quite a beating. Their bright yellow colour also makes them easy to spot. It is best to place a protection barrier at the ends of your warehouse rack. This way, it is still possible to load and unload your racks smoothly.

Finally, a word about rack identification. To know which goods are stored there, it is best to use a warehouse label. You have magnetic versions of a label holder that you can stick to a steel surface, but also versions with a self-adhesive layer. These are suitable for sticking to any material.