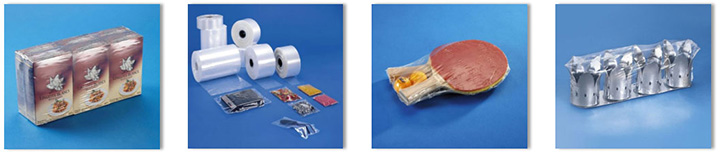

Say you have a range of products that are very different in size and weight. You would like to provide these products with plastic packaging. Because your products are so different, you will need to provide multiple sizes of plastic bags. But that can quickly become quite a hassle… You will need to stock and keep quite a few different plastic bags because each product is different. Fortunately, there are more practical solutions. Think shrink-wrap machines or sealing machines. Never heard of them? Then join us to see how they work and what benefits you get out of them!

1. What are the advantages of these machines?

A sealing machine and a shrink wrapping machine each have their own way of working but share a lot of advantages. We list them again for you here:

-

Suitable for all products: whatever the shape of your product, a sealing machine or shrink wrapping machine always adapts perfectly. Even products with the most erratic shapes are wrapped in plastic without any problem.

-

1 size of film suffices: maybe you used to use a different size of plastic bag for each of your products? Thanks to tubular film and shrink film, this is no longer necessary. 1 film suffices to make packaging of different sizes. Moreover, because you make your own plastic packaging, it is no longer necessary to stock a large stock of plastic bags yourself.

-

Fast packaging: The packaging process is largely semi-automatic. So you need to put less effort into providing your products with the perfect packaging.

-

Minimal effort: so the machine does almost all the work for you.

-

Strong protection: tubular film and shrink film protect your products against all external influences. Moisture and water as well as dust and dirt. The shrink film also holds your individual products together perfectly and is therefore very suitable for packaging e.g. bottles, CDs, a stack of books, etc.

As you can see, sealing machines and shrink wrap machines are the ideal solution if you want to wrap products of various shapes and sizes. The sealing machines and shrink wrapping machines at RAJA also always come with a 1-year guarantee.

]

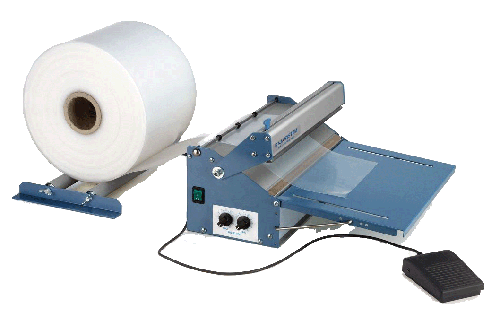

2. How do sealing machines work?

With a sealing machine , you create a plastic bag perfectly sized for your product. So the longer your product, the more tubular film you use. The shorter your product, the less tubular film you use. This way, you always avoid wasting packaging material. A sealing machine is equipped with a welding bar and works in combination with tubular film. The principle is very simple:

- Set the timer for the welding time.

- Place your product in the tubular film.

- Push the preheated welding bar down so that the tubular film is sealed into a bag.

- Cut off the tubular film.

- Lift the welding bar back up. Your customised plastic bag is ready!

► Which sealing machine should I choose?

There are obviously many different types of sealing machines available on the market. Your choice largely depends on your daily consumption and the width of the tubular film:

-

Small consumption: up to 4 bags/minute. If you only produce a limited number of packs per hour, it is best to choose the Eco seal machine. This sealing machine is light, compact and user-friendly thanks to an adjustable timer. The maximum width of the tubular film for this purpose is 200 mm. So it is perfect for packaging smaller products.

-

Medium consumption: up to 8 bags/minute. For medium consumption, it is best to switch to the Easy Packer© sealing machine. This machine is extremely user-friendly thanks to its built-in safety knife and adjustable timer. The Easy Packer© sealing machine is also available with a magnet to keep the sealing bar down during welding. This means less effort is required and you can weld more smoothly. The max tube film width for this machine is 400 mm.

-

High consumption: up to 14 bags/minute. The magnetic sealing machine SMS is the best solution for industrial use. It welds tubular film up to 680 mm wide. A good solution for fairly large products. This machine has a built-in safety knife. Moreover, the weld bar returns automatically to the top after sealing. The SMS sealing machine is also available with a foot pedal to keep your hands free during welding. So you can make bags tailored to each of your products at a high rate without any problem.

| Eco Sealmachine .  |

Easy Packer© .  |

SMS Sealer (Super Magnetic Sealer)  |

| Small consumption | Medium consumption | High consumption |

| 4 bags/min. | 8 bags/min. | 14 bags/min. |

| Film width: up to 200 mm | Film width: up to 400 mm | Film width: up to 680 mm |

| + Cutter + magnet in sealing bar + roll holder + Loading table |

+ cutting knife + foot pedal + base frame + roll holder + worktable |

► How do I choose the right tubular film for my sealing machine?

A decent sealing machine obviously includes the right tubular film. Choosing the right tubular film depends on the size and weight of your products.

- Transparent tubular film 50 micron: suitable for all your light products.

- Transparent tubular film 100 micron: suitable for heavy and sharp products.

- Transparent tube film 150 micron: suitable for very heavy and sharp products.

- Opaque tubular film 100 micron: the content is invisible and thus confidential.

Besides tubular film, you can also use a preformed plastic bag that has already been welded on one side. You then simply place your product in the bag and weld the open end closed with your sealing machine. To make your life even easier, you can combine your sealing machines with a roll holder for the tubular film or a product table. These accessories are available for the Easy Packer© and SMS variants. For the most ergonomic solution, combine your sealing machine with a support. This makes it easy to work while sitting down to use the sealing machine comfortably.

]

3. How do shrink wrapping machines work?

With a shrink wrapping machine , a plastic shell is created around your product thanks to the shrink film. You simply place your product in the shrink machine. As the polyolefin film is heated in the machine, it shrinks around your product. While with a sealing machine you create a plastic bag, with a shrink wrap machine you form a kind of “skin” that perfectly protects your product from external influences such as water, moisture, dust or dirt.

With a shrink wrapping machine, you can pack up to 300 products per hour. Combine our ESP shrink wrapping machine with a polyolefin film from Rajashrink or Cryovac CT. When selecting the right shrink film, all you have to do is ensure that the width of the film corresponds to the dimensions of the goods to be packaged. As the film shrinks nicely around your products, they will adapt perfectly, to any shape.