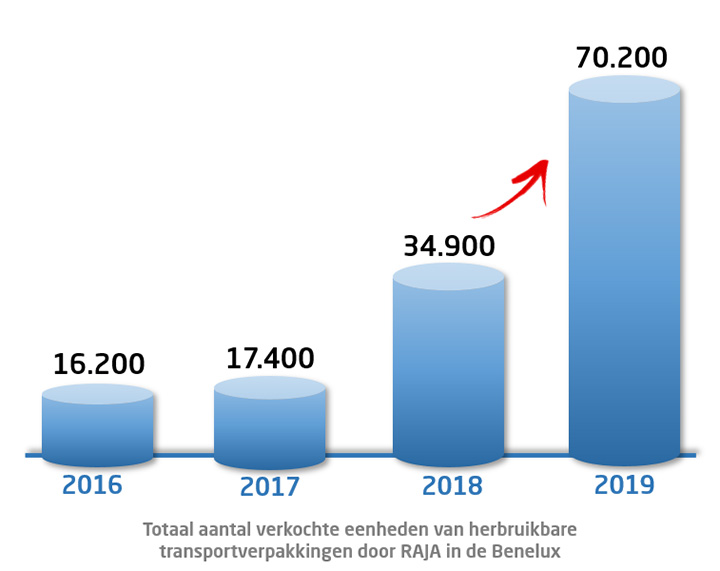

Although ordinary consumers probably don’t notice it, reusable transport packaging is becoming increasingly common behind the scenes. Their popularity lies precisely in that famous ‘reusability’. It is the key concept to achieve greener and more sustainable logistics in the future. Read all about this trend here and tick off the benefits for your business.

1. What is reusable transport packaging?

A first fact to mention: reusable transport packaging is often referred to by its English term RTP. That stands for Returnable Transport Packaging. An RTP is packaging that you can use multiple times. Unlike disposable packaging, an RTP is simply washed, stacked and sent back to the company of origin. This way, it is again ready for the next transport and they complete the circle. Examples include plastic pallets, courier bins or pallet boxes.

Reusable packaging is seen in more and more sectors. Food, automotive, chemical and distribution are just some of the most popular. RTPs are usually made of wood, metal or plastic. Certain variants, such as wooden pallets, go from company to company. This is possible thanks to their standard dimensions. Other packaging is owned by a specific company. They therefore remain within their internal cycle (e.g. courier bins).1

2. What are the benefits of RTPs?

► Save money and space

Cutting costs is something you do in two areas. First, in purchasing. Reusable packaging may be more expensive than disposable packaging. But that extra cost quickly turns into a greater return because you can use an RTP much more often.

A second saving is seen in terms of transport. An RTP is usually made of lightweight materials. These drive down CO2 emissions during transport. On top of that, the dimensions of these packages are optimally matched. Result? You can usually move more packaging per transport.

► Pack faster and safer

With an RTP, you pack your products a lot easier and faster. With a reusable courier box, for example, you no longer need separate cardboard boxes, as well as strapping bands, tapes, wrapping films, etc. Moreover, unlike disposable packaging, an RTP can be opened and closed multiple times. This allows you to check the contents without damaging the transport packaging.

Finally, reusable transport packaging is made of strong materials (which gives them a longer lifespan). As a result, your products are also better protected during choppy transport.

► A sustainable alternative

“Circularity” is the word of the future. By closing the material cycle, we reduce waste production and the use of raw materials.2 For example, a lot of RTPs are made of plastics such as PP and PE. Two materials that can be easily and repeatedly recycled.

Thanks to reusable transport packaging, the amount of waste produced by the logistics sector is significantly reduced. With a well-maintained RTP, you can make dozens, or even hundreds, of trips.

]3. These RTPs should not be missing with you

| Type of RTP |

Properties and use |

| (1) Pallets made of wood or plastic |

– Suitable for export (if ISPM15 compliant). – Perfectly stackable. – For transporting large quantities of goods. |

| (2) Pallet boxes made of plastic (PP) |

– Smooth inside protects the contents of the crate. – Ideal for non-food: sporting goods, textiles, clothing… – For storage or transport of light to medium-weight goods. |

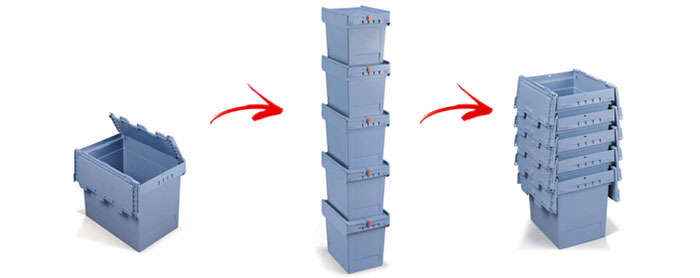

| (3) Courier bins made of plastic (PP) |

– Ideal for an internal transport cycle. – Stackableand nestable for maximum space saving. – For transporting small goods to/from another site. |

| (4) Stacking bins made of plastic (PP) |

– Maximum space utilisation: can be combined with other Euronorm stacking bins or europallets. – For storage or transport of small or light goods. |

Sources:

1 www.preventpack.be/nl/dossier/industri%C3%ABle-verpakkingen

2 www.valipac.be/nl/de-overgang-naar-circulaire-economie-vergemakkelijken/#onzeprojecten