Plastic: you know it all too well as a versatile, super-light and flexible packaging material. Advantages few other raw materials can match if you ask us. Admittedly, plastic is in a lot of cases the best solution for packing a product lightly and compactly. But does plastic score as well when it comes to recycling? Is transparent better than coloured? And what about bioplastics? These are just some of the five most frequently asked questions from the wonderful world of plastics. Curious about the answers? Then be sure to read on below.

1. What are the benefits of recycling plastic?

Plastic – or ‘plastic’ if you will – encompasses a wide range of variants. However, they all share the same raw material: petroleum. Currently, some 6% of the world’s petroleum is used to make plastic. Of that, 35-45% gets a life as plastic packaging.1 The vast majority of all that plastic is theoretically recyclable, provided you don’t mix up its different variants and therefore sort them properly.2 You can read more about that below.

A little less rosy news: we consume petroleum much faster than it is created naturally. That process can take many millions of years. As a result, petroleum is a raw material we need to use sparingly. Fortunately, there are several solutions to this. The first is to reduce plastic consumption. For instance, if you switch to a more compact box, you need less (plastic) padding. Secondly, you can also replace plastic with a completely different material. Here, paper and cardboard spring to mind as sustainable alternatives. And finally, of course, there is recycling: one of the best solutions in creating a circular economy. Recycling provides:

- Lower consumption of oil – this puts less pressure on existing oil supplies.

- Lower CO2 emissions – recycling takes less energy than making new material.

- Less litter – if we collect and sort plastic more intensively, less material ends up in landfills.

2. Is transparent plastic easier to recycle?

You quite regularly see bubble wrap or bags to which the manufacturer has added a green dye. That green appearance makes it clear to consumers that the plastic is made entirely (or partially) from recycled material. The downside of this is that the plastic is more difficult to recycle again at a subsequent stage. In the process, the green dye ‘pollutes’ the process. So if you are smart, always choose recycled plastic packaging that is completely transparent.

Examples of this type of recycled and transparent plastic are air cushion bags and bubble wrap. We use this type of material to wrap products and protect them from shocks, among other things.

So how can you tell the difference between recycled plastic and virgin plastic if both are transparent? The answer to that is actually “not”, or at least “barely”. So it is always advisable to make it clear in your communication that you have chosen an eco-friendly packaging material. That way, the end customer knows that your transparent packaging is much “greener” than he would think at first glance. Good for the environment, and of course also for your sustainable corporate image.

3. What types of plastic can you recycle?

Plastic packaging is, in theory, all recyclable. A minor exception is packaging that has contained hazardous chemicals, for example. Such packaging is often processed through a separate sorting cycle. But back to ‘ordinary’ packaging now….

The prerequisite for recycling is to keep the different types of plastic strictly separated. Separating it ensures the quality of the recycled end product. To know which type of plastic you have in your hands, look out on the packaging for a small triangular symbol with a number in the middle. Below is an overview of the types of plastic that are easiest (and most frequent) to recycle.

| Type of plastic |

Properties |

Applications |

Polyethylene terephthalate |

– Transparent and shiny | – Transparent bottles – Blister packs |

Polyethylene High Density |

– Opaque (≈ milk glass) – Tough – Very Strong |

– Strong bags or pouches – Water bottles |

Polyvinyl chloride |

– Light – Flame retardant – Electrically, thermally and acoustically insulating |

– Toys – Tape – Car parts – Floors |

Polyethylene Low Density |

– Fairly soft and tough – Often transparent |

– Air cushion bags – Grip bags |

Polypropylene |

– Similar to PE, but much stronger – Glossy, colourfast and heat-resistant |

– Furniture – Tape – Presentation cases – Stacking bins |

Polystyrene |

– Shock resistant – Hard and smooth surface |

– Foam material – Disposable cutlery – Drinking cups |

A polypropylene plastic carrier bag, for instance, can be reused up to 400 times to carry your shopping. If it does wear out, it is ready for recycling and can easily be given a new life. That way, you come full circle.

4. How is plastic recycled?

Initially, plastic needs to be sorted accurately by type.3 Part of that responsibility lies with households and businesses. Another part is carried out in the sorting centres thanks to automated processes. This is the case, for example, for all the materials we throw away collectively in the PMD bag.

Once the plastic has been separated by type, it can be shredded or ground into granules and then washed. Finally, through various techniques, the granules are melted and transformed. They are then used to make new products. Good to know: the better households and companies sort, the more often they can repeat this process.

5. How can bioplastics be recycled?

Besides petroleum, there are also plastics based on biological sources, plants for example. Unlike conventional plastics, these biological variants are more easily degradable and renewable. Polylactic acid, abbreviated PLA, is one example.4 PLA is made from plant material (e.g. cane or maize) that renews itself every growing season. In theory, these sources are therefore inexhaustible, as well as absorbing CO2 from the air to grow. Want to know more? Read all about the other advantages and applications of PLA here.

Most bioplastic products are printed with one or more specific logos. Examples include the TUV Austria logo or the Kiemplant logo. Pending clear regulations, small quantities of bioplastics are best disposed of with general residual waste. An exception is packaging that explicitly states that it is ‘biobased’. These types of plastics have almost the same polymeric properties as regular plastic. As a result, you may also sort them with regular plastic waste (PMD). Good to know: for large quantities, bioplastics can sometimes be collected separately by your regional waste collector. It is best to ask them about this.

6. Additional figures and facts about plastic

- The first synthetic plastic was invented in 1907 by Belgian-American chemist Leo Baekeland. His invention was called ‘Bakelite’. However, it waited until World War II before plastics were massively used (in cars and artillery, among other things).

- The word plastic is actually an abbreviation. It comes from ‘thermoplastic’ which in turn refers to the fact that these materials can be deformed by heat.2

- By 2030, the European Union wants member states to recycle 55% of all plastic packaging on the market. A target that is almost in sight for the Netherlands. In 2021, 50% of all plastic packaging was reused.

- Recycling PET requires up to 60% less energy than producing new PET.5

- Plastic bottles are becoming lighter and lighter. In 1971, a 1.5-litre SPA Reine bottle still weighed 56.6g. In 2013, the same bottle weighed only 28.5 g. New techniques therefore allow manufacturers to make the same quality bottles with less material.6

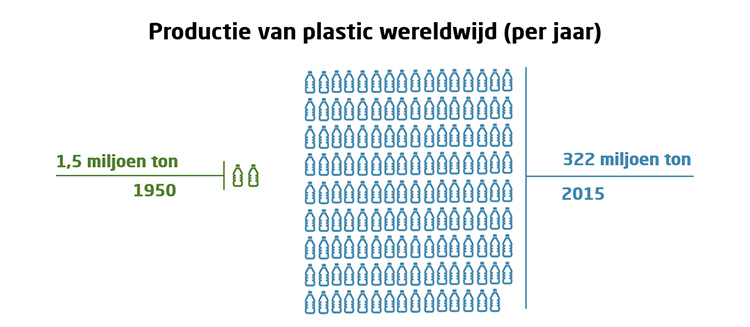

- Plastic production has grown exponentially in 65 years. From 1.5 million tonnes in 1950 to 322 million tonnes in 2015:5

Sources:

1 www.weekend.knack.be/lifestyle/maatschappij/de-wereld-van-plastics-in-cijfers-van-de-verpakkingsindustrie-tot-in-de-kledingkast/

2 www.iksorteerinmijnbedrijf.be/hoe-goed-sorteren/plastic-en-piepschuim/

3 www.fostplus.be/nl/sorteren-recycleren/alles-over-recyclage/pmd-recycleren/

4 www.eoswetenschap.eu/technologie/bioplastics-een-primer/

5 www.europarl.europa.eu/news/nl/headlines/society/20181212STO21610/plastic-afval-en-recycling-in-de-eu-feiten-en-cijfers/