In this article, we explore the vast world of pallets. In particular, we focus on INKA wood fibre pallets: a remarkably light and durable member of the pallet family. They are an excellent solution for handling and transporting your goods. Are you curious what added value they can bring to your business? Then be sure to read on.

1. What are INKA wood fibre pallets and how are they made?

Pallets were originally made from a set of wooden boards… During World War II, this type of pallet was massively used by the US military to ship goods to Europe. This heralded the beginning of their immense popularity. Their great success subsequently led to other variants being designed, made of other materials. Thus, in addition to plastic and cardboard, pallets were also designed from wood fibre – such as the models from the German brand INKA.

A wood fibre pallet is made of compressed old and used wood. This wood was first shredded and dried via a high-pressure forming process. Both the wood chips and the binding agent (urea resin) are of completely natural origin. At the end of its life cycle, a wood fibre pallet can be easily transformed into a new pallet again, or even used as fertiliser. At RAJA, you can choose from three types:

| Mini pallet 400 x 600 mm 400 x 800 mm 600 x 800 mm  |

Standard pallet 800 x 1200 mm 1000 x 1200 mm .  |

Maritime pallet 760 x 1140 mm 1140 x 1140 mm .  |

| Small-size pallets for transporting a limited amount of goods. | The most versatile variant, meets uniform dimensions. | Suitable for loading sea containers due to their adapted dimensions. |

2. What are the advantages of INKA wood fibre pallets?

All INKA wood fibre pallets are very light, space-saving and meet a range of essential standards. Thanks to their wide range a sizes, they are a perfect solution as transport pallets, compact displays, or container pallets. Their use can provide companies with numerous benefits, such as more efficient logistics, lower transport costs and better management of natural resources. Moreover, choosing sustainable pallets can contribute to a more eco-friendly and environmentally conscious image – for your company too!

- Economical: These pallets have an excellent value for money, allowing you to keep your storage and transport costs well under control. Thanks to their production technology, they comply with the ISPM15 standard, so you don’t have to worry about additional costs to ISPM15 countries.

- Strong adhesion: The patented adhesion technology used in the production of INKA wood fibre pallets ensures a strong and solid design. This makes the pallets suitable for transporting medium to heavy loads.

- Light: INKA pallets are remarkably lighter than traditional wooden pallets. Despite their light weight, they can still support a considerable load, making them versatile. The largest formats can support static loads of up to 2,700 kg.

- Space-saving: The pallets are easily stackable and nestable (see image below), taking up to 50% less space than ordinary europallets.

- Standardised: INKA pallets are designed in accordance with international standards. You can therefore easily use them in combination with numerous pallet trucks or automated storage systems.

- Quality certificates: INKA pallets are subjected to strict controls. They are often certified to ISO 9001 and ISO 14001 standards.

- Global availability: INKA pallets are distributed worldwide and widely used in various industries, including the food, automotive, chemical and pharmaceutical industries.

- Safe: these pallets contain no nails, splinters or sharp corners, making them safe to handle by your warehouse staff.

]

3. A sustainable solution for your transport

INKA wood fibre pallets are mainly made from PEFC-certified wood, sourced from sustainably managed forests. This helps reduce environmental impact and encourages responsible forest management. Moreover, they are easily reusable and well recyclable. Once the life cycle of the pallet ends, they can be recycled or converted for other uses. As a result, (residual) waste can be kept to a minimum.

4. How should you load and wrap a pallet?

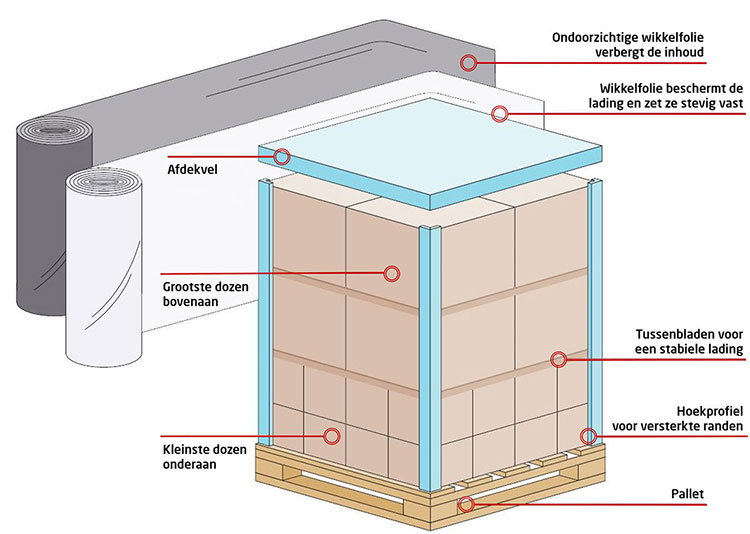

Finally, we look at some tips for safely loading and then wrapping your wood fibre pallet. Start by placing the heaviest boxes/loads at the bottom. Are there no big differences in weight? Then place the smallest boxes at the bottom and the largest at the top. You will notice that this produces the most stable pallet stack. In addition, never place your boxes over the edge of your pallet. This increases instability and can cause your loads to be damaged.

Stacking is followed by wrapping. With stretch film, you ensure that your cargo becomes much more stable. Moreover, your goods are better protected against moisture and your pallets can be loaded more easily into trucks and containers, for example. Do you need to wrap more than 15 pallets per day? Then choose an automated system with a film wrapper. A film wrapper adapts perfectly to the shapes of your pallet and load. As a result, your pallets are wrapped more stably and with an ideal quantity of film: never too much and never too little. There are machines available that can process up to 250 pallets per day. So that equals a boost to your time savings and productivity.