Wrapping film around a pallet is an essential part of your packing process. It guarantees like no other that a large stack of goods can be shipped safely. At first glance, handling stretch film can seem a laborious task for your warehouse staff; especially when he or she has to do it manually. RAJA therefore collected 7 common mistakes you can easily avoid. This way, you will learn to prepare your pallets for dispatch better, more safely and more efficiently.

Tip 1: Choose the right material for your palletisation

Before you start wrapping your pallet, you need the right material for this. A smart investment in the correct material will save you a lot of headaches later on. You should therefore consider the following products when making your choice:

- The right type of pallet: pay extra attention to the maximum load your pallet must be able to support, the number of slots at the bottom and, of course, the dimensions.

- The right type of box: consider palletisable boxes. These have a format adapted to the dimensions of standard pallet sizes.

- The right type of wrapping film: for medium-sized pallets with slightly protruding loads, it is best to choose pre-stretched film. This makes manual film wrapping a lot easier (and more economical) for your warehouse staff.

Tip 2: Stack your products stably

This brings us to one of the most common mistakes. If your boxes are unstable on a pallet, that pallet itself will also become unstable. Result? There will be a greater risk of the pallet toppling over during transport and your products will be damaged.

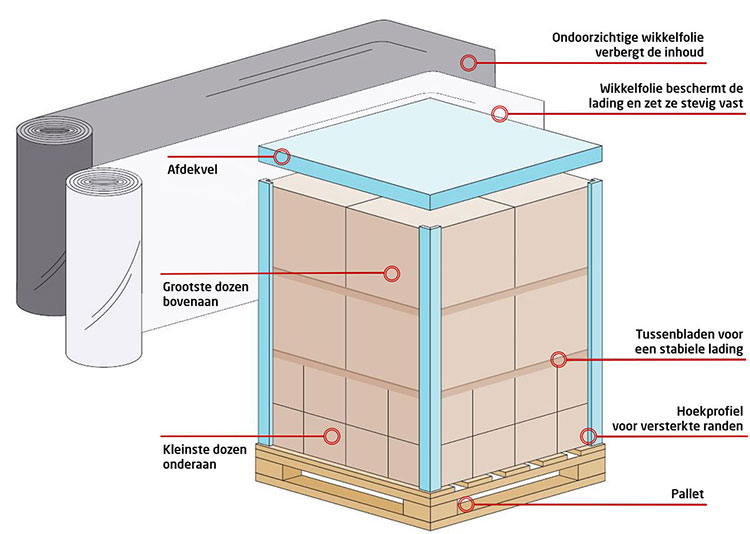

Start by stacking your boxes in a stable way. The smallest boxes should be at the bottom of the stack. Leave no space between the different boxes, and it is best to place an intermediate sheet between each layer. This will considerably increase the stability of your pallet, making it easier to wrap and transport afterwards.

An extra tip from RAJA: as an alternative to a traditional pallet, you can opt for a pallet box. With this, you always keep to the maximum dimensions of the pallet, so the boxes would not protrude over the sides. This is a great solution if you have many temporary workers in your warehouse and little time to train them individually. With a pallet box, you are always assured that the quality of your palletisation is guaranteed.

Tip 3: Manually wrap your pallet in the right direction

Your stretch film has a specific direction in which it should be applied: the sticky side should face your cardboard boxes in doing so. The smooth side of the film will be on the outside. Some rolls you can apply clockwise, others anti-clockwise.

Wrapping a pallet in the wrong direction carries risks that you definitely want to avoid. Firstly, the film will not adhere to your load if the sticky side is facing outwards. Secondly, in that case your pallet is not well protected from dust and other storage conditions that could damage the contents. So bear in mind that you need to train your warehouse workers correctly on how to apply the wrapping film properly.

]Tip 4: Wrap your pallet evenly

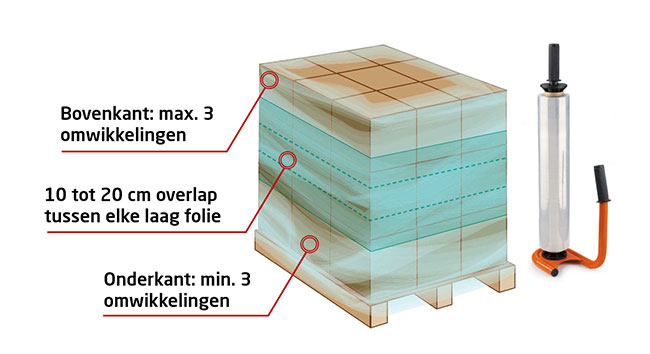

When wrapping a pallet load by hand, make sure that each part of the load is wrapped evenly. We therefore recommend an overlap of 10 to 20 cm of film between each strip. This way, your cargo will be optimally protected from top to bottom.

If you don’t do this, chances are your pallet load will be unstable in the areas that are less well wrapped. These strips would also be more exposed to damaging storage conditions and shocks during transport. All factors that could damage your goods.

Tip 5: Protect your pallet from weather conditions

Are your pallets stored outside? Or in an area subject to environmental factors that could damage your goods? If so, opt for an extra form of protection! This can start with the material the pallet is made of: plastic pallets, for example, are waterproof, while wood fibre pallets are more insensitive to temperature fluctuations.

Add one of the packaging materials below to protect your pallet load even better against harmful weather conditions:

- Use a cover sheet that you simply slide over your pallet load. This way it is better protected from weather conditions such as rain.

- Use opaque black stretch film to protect your cargo from sunlight. In addition, this dark film protects against theft as your products are shielded from prying eyes with bad intentions.

Tip 6: Install appropriate signage in your warehouse

To ensure everyone’s safety, it is recommended to provide appropriate signage throughout your warehouse. This will help your warehousemen wrap correctly:

- Rules for correct palletising, including best techniques and appropriate materials.

- An indication with the maximum pallet load for each type of pallet used.

- Handling instructions: should the pallet be loaded on a transpallet? On a forklift truck? Should they be handled manually with gloves?

Tip 7: Keep in mind the risks of MSA

Packing and wrapping pallets are tasks that carry obvious risks of musculoskeletal disorders (MSA). Just think about the impact of too repetitive work, lifting too heavy loads, etc. If you do not address these processes, they can lead to physical complaints in your warehouse workers, and possibly even increase absenteeism.

How do you best address MSA risks? If your warehouse workers need to wrap more than 12 to 15 pallets a day, it is advisable to opt for a film wrapper. This machine takes over most of the heavy and repetitive tasks so that your body is significantly less stressed. Thus, pallet wrapping remains a pleasant and easy job for everyone.