Food, medicines, cosmetics, yes even the most sensitive equipment… We buy and sell it all online. To guarantee the quality of all these products, they are often shipped refrigerated. A challenge for transporters that should not be underestimated. But have you ever considered using paper as a refrigeration solution? Here, we look at how you can use recyclable paper and cardboard to keep your head and box cool.

1. Active or passive cooling?

If you ship large quantities of one and the same product, then a refrigerated cart is probably the best solution. We also call this active cooling: the low temperature here is constant and is produced outside the packaging.

If you need to ship diverse products, then the story becomes slightly different. An example: while vegetables such as carrots and leeks feel perfectly at home at +1 to +2 °C, tomatoes find a temperature of +12 to +16 °C just comfortable.

In the latter cases, passive cooling is recommended. It is then the packaging itself that will keep your produce cool. The advantage of this is that you can set the temperature separately for each package. This gives you more flexibility and is a lot cheaper. Paper is one of the materials that lends itself perfectly to this.

2. What are the advantages of paper?

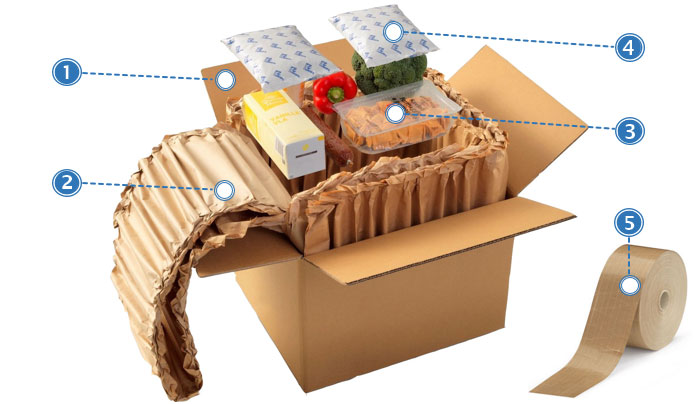

You might first want to know why paper insulates so well now? Paper pulp actually has naturally insulating properties. In the construction industry, for example, paper flakes are used as insulation material. The real secret is in the shape. You can fold paper into a kind of layered and wavy cushions (we call them ‘buffer cushions’ here). You can see this clearly in the picture below. The air between these folds then forms a temperature buffer.

Our partner Ranpak has developed a machine – the WrapPak® Protector – that makes the perfect kind of buffer cushions. The corrugated structure of the cushions is unique and enhances the insulating effect. How about all these benefits:

- Cost-saving: paper is one of the cheapest packaging materials on the market.

- Sustainable: paper is a renewable raw material and perfectly recyclable.

- Space-saving : unfolded, the paper hardly takes up any space. The WrapPak® Protector machine is also compact so it fits into any work space.

- Flexible: paper can easily be folded into the desired shape without breaking or losing strength.

- Protective: in the form of buffer pads, paper is not only insulating, it also protects against shocks and fills empty spaces in a box.

- Production on demand: the paper buffer cushions are produced only when you need them, so you don’t need to build up unnecessary stocks.

3. How to use paper as a cooling solution?

For those who want to get started themselves, we have worked out the following step-by-step plan. All you need to get started is a cardboard box and buffer paper.

- [1] Take a box made of twin or triple corrugated cardboard. These boxes have a thicker cardboard wall so they better stop temperature fluctuations from outside.

- [2] Cover all inside walls with buffer paper. The more layers you use, the greater the insulating effect.

- 1 layer = for transport at room temperature.

- 2 layers = for refrigerated products (24-36 hours active).

- 3 layers = for frozen products and frozen packs (up to 48 hours active).

- [3] Place your product in the box.

- [4] Add one or more cooling elements (optional). Remember to add one or more layers of buffer pads on top of your product.

- [5] Close your box with tape that can withstand low temperatures. You can opt for a gummed adhesive tape for this, for example. Extra conveniently, you may sort this tape together with the cardboard box.

4. Paper versus other materials: do the test

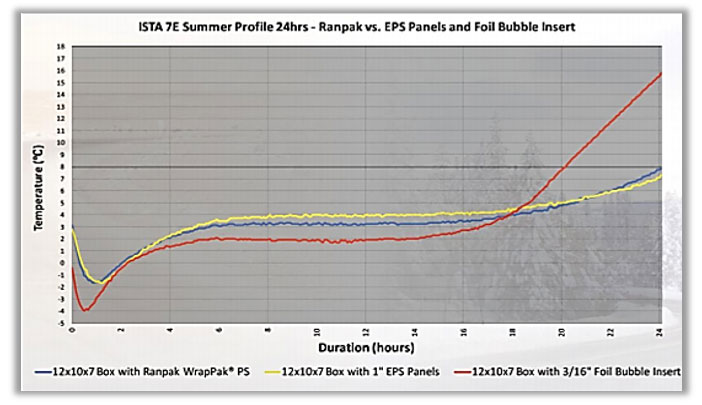

The test below from Ranpak shows how effective paper is as a cooling solution. For this test, a chocolate bar was packed in three separate boxes. Each box measured 30 x 25 x 18 cm and was fitted with two additional cooling elements. Packaging was done at a temperature of +5 °C. Three times the same conditions, but with one difference: the padding material inside the box. One chose Styrofoam (yellow), bubble wrap (red) and paper (blue) from the WrapPak® Protector machine.

Initially, the temperature curves are quite parallel. After 18 hours, however, we see that the bubble wrap begins to lose its effectiveness. 24 hours after packing, the temperature has already risen to +16 °C. Both Styrofoam and paper can produce better results: after 24 hours, the temperature has risen to just +8 °C. This test took place at a set outdoor temperature between +26 and +32 ⁰C.

Conclusion? Paper and cardboard are – when used correctly – a great cooling solution to keep your products fresh. Moreover, after use, the box and padding can be sorted and recycled together. Nice and simple and sustainable!

Read more: don’t give heat a chance with these cooling boxes and cooling pads