Probably the standard wrapping film you are thinking of is transparent. Am I correct? This wrapping film is therefore the best known of its kind. But there is so much more; for example, wrapping film with a colour. Here we teach you how coloured wrapping film makes it easier to identify your pallets, protect them from theft, etc.

1. What is wrapping film used for?

Wrapping film or stretch film is indispensable when transporting goods on a pallet. By wrapping your stacked pallets with stretch film, you guarantee safe transport for your products: they will not shift on the pallets and will also be protected from dust, dirt and moisture. Every pallet leaving your warehouse should, at best, have a solid layer of stretch film as protection. By the way, you can read all about the correct use of stretch film in the following article.

2. The advantages of coloured wrapping film

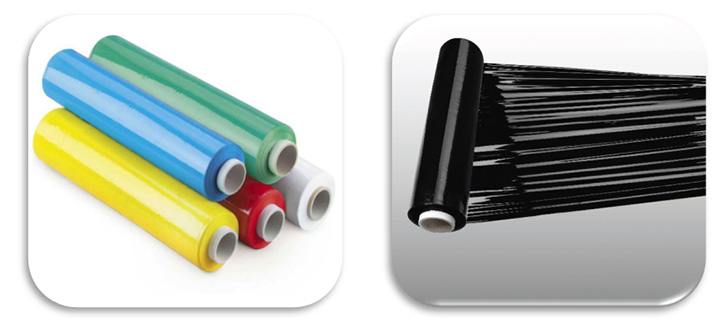

Wrapping film is transparent as standard. This allows you to immediately know which goods are involved. After all, you can see them through the film.

Wrapping film can also be opaque black. Black wrapping film is used to give your products extra protection against theft during transport, transhipment or storage. The dark colour of the film ensures that your pallet is completely opaque. This way, the contents of your shipments remain confidential and you attract less attention from thieves. Incidentally, black film also comes in the form of a protective cover that warehouse operators can easily place over their products to hide them.

► In addition to black, wrapping film is sold in 5 eye-catching colours. This allows you to recognise your pallets at a glance. This stretch film is available in blue, red, yellow, green and white. The bright colours of the film make it much easier to distinguish your pallets and goods. You can match each colour to, for example, a different type of product, courier service, customer, etc.

Another additional advantage: thanks to coloured wrapping film, your products and packaging are less likely to discolour. This is because the film blocks sunlight better.

- There also anti-static wrapping film exists? With this you optimally protect your electronic devices and components.

- There is also an elastic film net exists? The holes in the film net allow your goods to ventilate optimally. A non-negligible protection, as it prevents the formation of condensation.

- There pre-stretched film exists? This saves you considerably on your film consumption as you need fewer metres of film to cover and protect the same surface area.

3. Manual or machine wrapping film application?

]Transparent or coloured wrapping film can be applied in two ways: manually with a hand dispenser or mechanically with a pallet wrapper. If you need to process more than 15 pallets per day, it is best to opt for machine wrapping.

► Manual wrapping

Companies that prepare only a few pallets for dispatch every day should opt for a hand unwinder to perform this task manually. This will be the most economical solution. Check out how best to apply this film in this article.

► Machine wrapping

Do you need to wrap more than 15 pallets per day? Then it’s best to opt for a pallet wrapper. Thanks to this machine, your warehouse worker will save a lot of valuable time in the first place. You will also save on your stretch film consumption. The machine never uses more film than is strictly necessary. Broadly speaking, you can choose between two types of film wrappers: one with a brake system and one with an automatic pre-stretch.

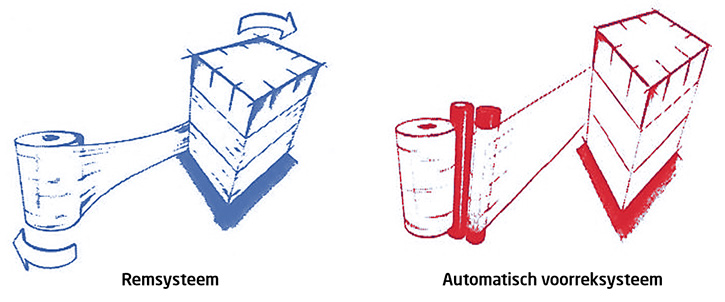

- Mechanical braking system = The ones with a braking system are technically the simplest and therefore the cheapest. The film is stretched by means of a brake (up to a maximum of 100%). As a result, the film narrows a little. You will therefore need slightly more film per wrap. To avoid this, it is best to use pre-stretched film with this system.

- Automatic pre-stretching system = The machine will optimally pre-stretch the film – by up to 400%. The film rolls between two motorised axes placed very close together. The result of this process is a film that is no longer narrowed and covers your pallet to the maximum extent.

As you can see below, you have a choice of different versions of machines:

| Type of film wrapper .  |

Number of pallets per day & Type of load  |

Advantage . |

| (1) Mobile wrapper | – From 15 pallets per day – Homogeneous or heterogeneous loads. |

The cheapest solution. |

| (2) With turntable* | – Up to max. 50 pallets per day. – Homogeneous loads. |

The mechanical brake ensures even winding. |

| (2) With turntable and front rack system** | – Up to max. 150 pallets per day. – Homogeneous or heterogeneous loads. |

With automatic pre-stretching for max. film saving. |

| (3) With swivel arm* | – Up to max. 250 pallets per day. – Unstable loads and goods too heavy for a turntable. |

With rotating arm that wraps the film around very heavy pallets wrapping. |

| (4) Wrapping robot*** | – Up to 250 pallets per day. – For loads that cannot be placed on a wrapping platform due to their shape or weight. |

Automatically rotates any load (min. 60 x 60 cm). |

* Equipped with braking system.

** Equipped with automatic front rack system.

*** Available in a variant with a braking system or an automatic front rack system.