Admit it: closing boxes with tape seems very simple. However, there are many things to consider. So how do you best choose, stick and store PP or PVC tape? Our packaging experts explain everything below.

1. Closing boxes with tape: manually or mechanically?

For best results, it is recommended to stick the tape at a temperature of +15 °C or more, on a dry and dust-free surface. By the way, in winter it is more difficult to stick tape. Cold often involves moisture; this would then mean applying your tape to water which is, of course, almost impossible. Sealing your boxes can be done in two ways:

-

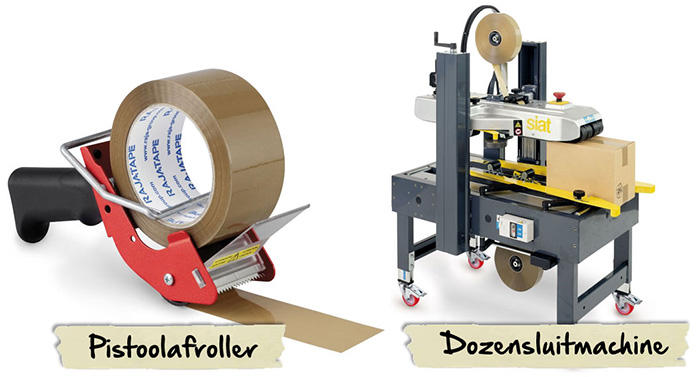

Manually: with a pistol dispenser (for PP or PVC tape) you close cardboard boxes very easily and quickly. Make sure you apply enough pressure to the tape, otherwise it will come loose or crease. After sticking, tilt the pistol dispenser slightly forwards and then towards the surface you want to seal. This will cause the teeth of the unroller to cut the tape. Done! By the way, tape is‘pressure sensitive‘, which means that you always have to press it down after manual gluing.

-

By machine: with a carton sealer you can easily process up to 10,000 packages a day! What should you pay attention to with such a machine? Check that it exerts the right pressure on the pressure rollers and think about regular maintenance. That way you can continue sealing parcels without any worries.

2. Three techniques to seal your box

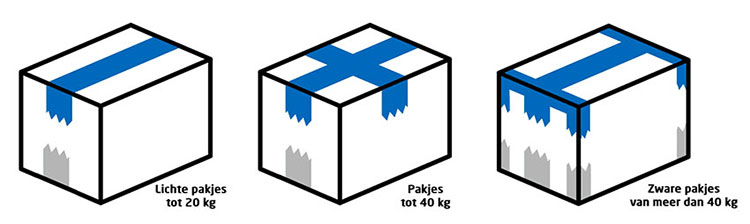

| Light packages from < 20 kg |

► Apply the tape in a U-shape. Attach the tape along the entire length (where the flaps meet) at the top and bottom of the package. |

| Medium-weight parcels from < 40 kg |

► First make a U-shaped closure and then reinforce with a second U-shape along the short sides of the box. This is ideal for transporting medium-heavy parcels or for parcels that will be stored for long periods. |

| Heavy parcels from > 40 kg |

► Closing boxes with tape in a H-form is the safest closure. Stick the tape along the entire length of the box, both at the top and bottom. Two extra strips of tape as reinforcement are applied over the edges each time. |

3. Which plastic tape best suits your needs?

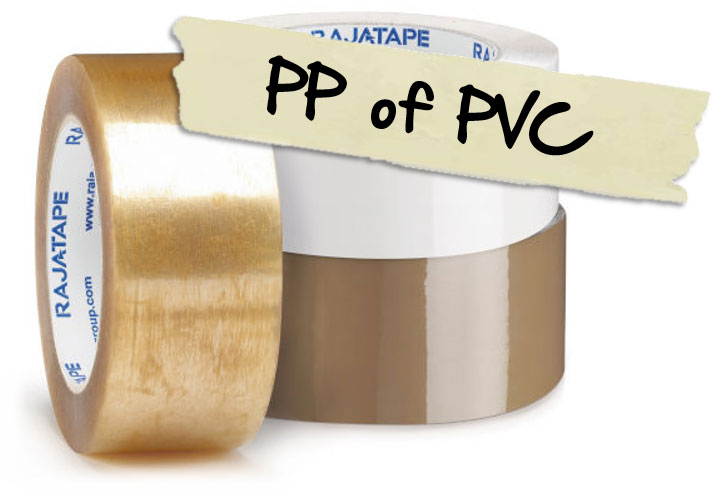

Which is the best solution for you? PP tape or PVC tape? Above all, remember this: if you want to close boxes with tape, keep in mind the weight and material of your box when making your choice.

► The strength of your PP or PVC tape

The thickness – and therefore the strength – of PP or PVC tape is expressed in microns (1/1000 mm). The heavier your package, the thicker the tape should be. It is then best to choose a higher micron value. PP tape and high-quality PVC tape adhere well to all types of surfaces. If you use cardboard boxes, consider using a paper gummed adhesive tape. These often offer the strongest closure because the adhesive tape becomes one with your box.

| Thickness of tape in microns | Package weight |

| 28 microns (or lower) | ► For light parcels, up to 20 kg. |

| 32 micron | ► For medium-weight parcels, up to 30 kg. |

| 35 micron | ► For heavier parcels, up to 35 kg. |

| 38 micron (or higher) | ► For the heaviest parcels, above 35 kg. |

► The adhesive of your PP or PVC tape

- PP tape with acrylic adhesive (water-based) remains beautifully transparent and is used for making low-noise tapes.

- PP tape with synthetic rubber adhesive (hot melt) is cheaper than natural rubber glue. It sticks almost immediately. However, this glue is not suitable for long-term use and cannot withstand temperature fluctuations as well.

- PP tape with natural rubber adhesive (solvent) is the most common adhesive tape. Because solvent adhesives have high adhesive strength, they are often used outdoors. Temperature fluctuations and humidity are not a problem (at least in the short term).

- PVC tape with natural rubber adhesive (solvent) has the best quality and longevity. It is slightly more expensive to buy, though.

► How can you tell the difference between PP and PVC?

To tell them apart, you need to test elasticity: In fact, you can stretch PVC tape much further than PP tape. A quick test: stretch a piece of tape and tighten it. Then try poking through it with a pen. If you can poke a hole, it is PVC tape. If the tape snaps or tears, it is PP.

You can often tear PVC tape by hand. With PP tape, tearing is less easy, making a gun dispenser always necessary.

4. How do you best store plastic tape?

We’ve already talked about the ways you should use tape, but how should you store that PP or PVC tape? Packaging tape requires specific care: it is best to store it at room temperature (+18 to +25°C), in a dry place, out of the sun and preferably in its original packaging.

Store your tape upright so that the end of the tape sticks under the roller. Do you have boxes with several rolls? Then keep the silicone paper separating them. This will prevent the rolls from sticking together.

Tape can be stored for about a year. After that, the glue crumbles. So be sure to check the production date on the lot number. So remember: keep a close eye on your stock. Your stock cannot be too small because you need to make ends meet; but it cannot be too large either because tape has an expiry date.

- Store your tape for a maximum of 6 months. A nice exception: PP tape with acrylic glue can easily be stored for up to 1 year.

- Ideal temperature for storage: between +18 and +25 °C.

- Ideal humidity for storage: maximum 65%.

- For storage temperatures < +15 °C: allow the tape to warm up in a heated room for at least 24 hours before use. Definitely do not warm up hastily!.

- At storage temperatures > +25 °C: in the short term, this will not cause any harm. In the longer term, however, the adhesive may start to ‘sweat’, which can cause it to run down the sides of the roll, resulting in loss of quality.

5. Packaging tape: real protection against theft

Theft of goods is a real problem in the shipping and transport industry. Fortunately, nowadays several means can prove whether or not a package was opened during transport. Closing boxes with tape is therefore also an option:

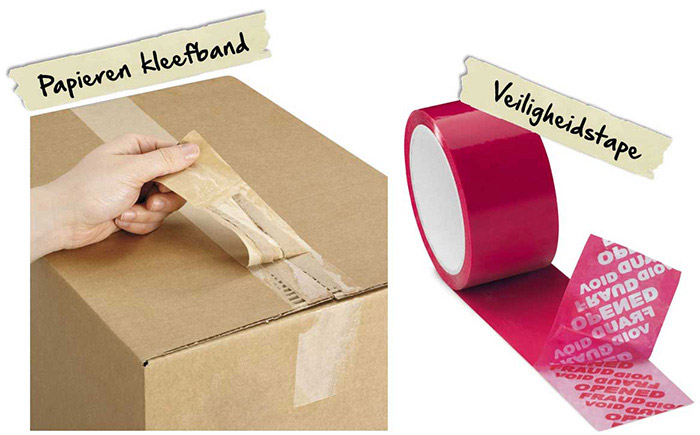

- Paper gummed adhesive tape is one of the most effective closures for cardboard boxes. The glue penetrates the cardboard. If you want to remove the tape afterwards, it is immediately and irreparably visible. If you use one of these paper gummed adhesive tapes, you will need an adhesive tape dispenser. This device moistens the adhesive tape so that the glue immediately penetrates the cardboard of your box.

- Security tape When removed, leave a message on the box (usually you will see ‘opened’). This makes it easy to know whether your parcel has already been opened or not.

- Apply your tape at a temperature above +15 °C.

- The H-shaped closure is the safest closure available.

- Take into account the strength of your tape and the type of adhesive.

- Store your tape at room temperature and for up to 6 months.

- Use appropriate security tapes to quickly detect theft.