Pallets: we know them in different shapes and sizes. Whether they are made of wood, plastic or cardboard, they all share one characteristic: they are the basis for moving and protecting your goods. Check out all types here, learn to distinguish their advantages and find out how best to prepare your pallet for transport.

1. What dimensions do pallets have?

Within the pallet family, there are two formats most commonly used worldwide. On the one hand, you have the US size or ISO size of 1200 x 1000 mm. These pallets are mainly used in the US, Canada and Japan. Note: they often do not conform to the dimensions of European trucks.

On the other hand, you also have the European size of 1200 x 800 mm. Incidentally, in Europe there is another slightly smaller variant, the display pallet, measuring 800 x 600 mm. These two pallet variants comply with the specifications of the European Pallet Association and are often printed with the logo EUR or EPAL.

- American pallet = 1200 x 1000 mm

- European pallet = 1200 x 800 mm

- Display pallet = 800 x 600 mm (also available in 600 x 400 mm)

- There are more pallets in circulation in Europe than residents? According to the last census dating from 2015, there were 3 billion pallets in the EU. That was 4 per inhabitant.

- The pallet is actually not that old? It was patented in the 1930s by George Raymond and his friend Bill House.

- Wooden pallets are made of different types of wood? For the load-bearing parts, they often use strong oak. For the other parts with rather use pine (or pine).

2. Choose the right insert and carrying capacity

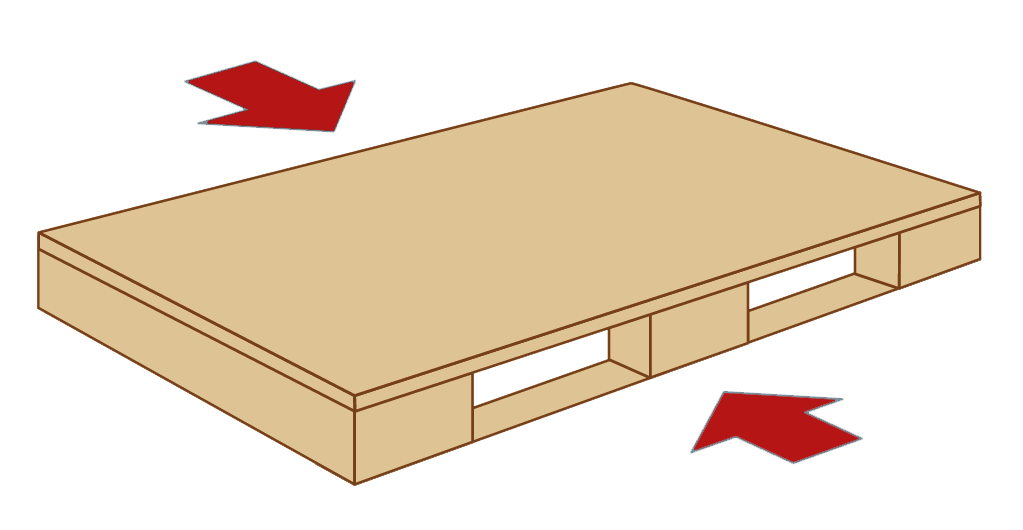

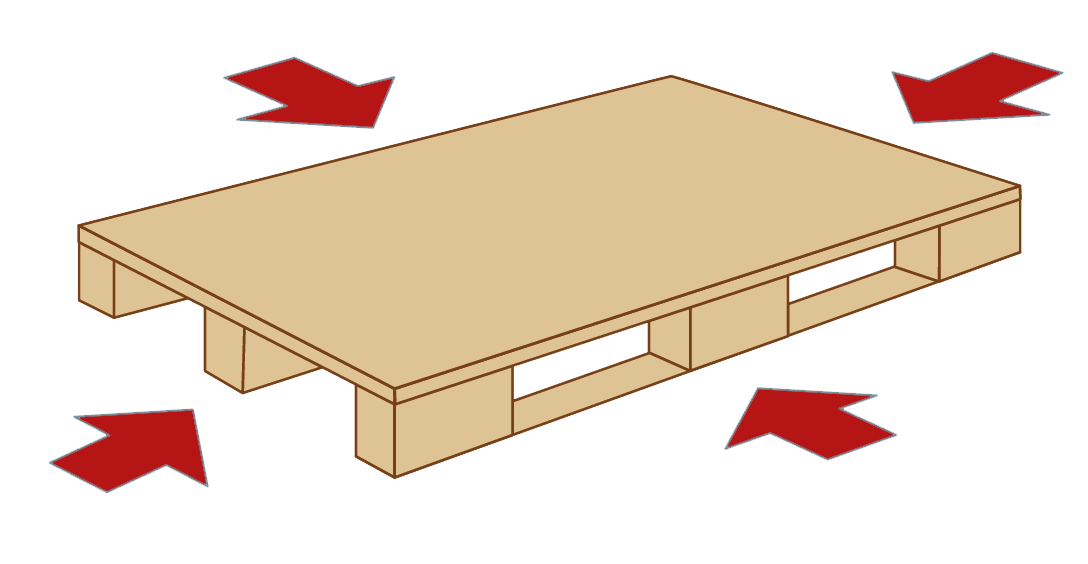

The easiest way to move pallets is with a pump truck. To do this, your pallet is fitted with ‘inserts’. These are notches into which you insert the forks of the pump truck. You can choose pallets with 2 or 4 insertions:

| 2 insertions | 4 insertions |

|

|

| Allows the pump truck forks to be used only on the long sides of the pallet. | Allows pump truck forks to be used on the four sides of the pallet. |

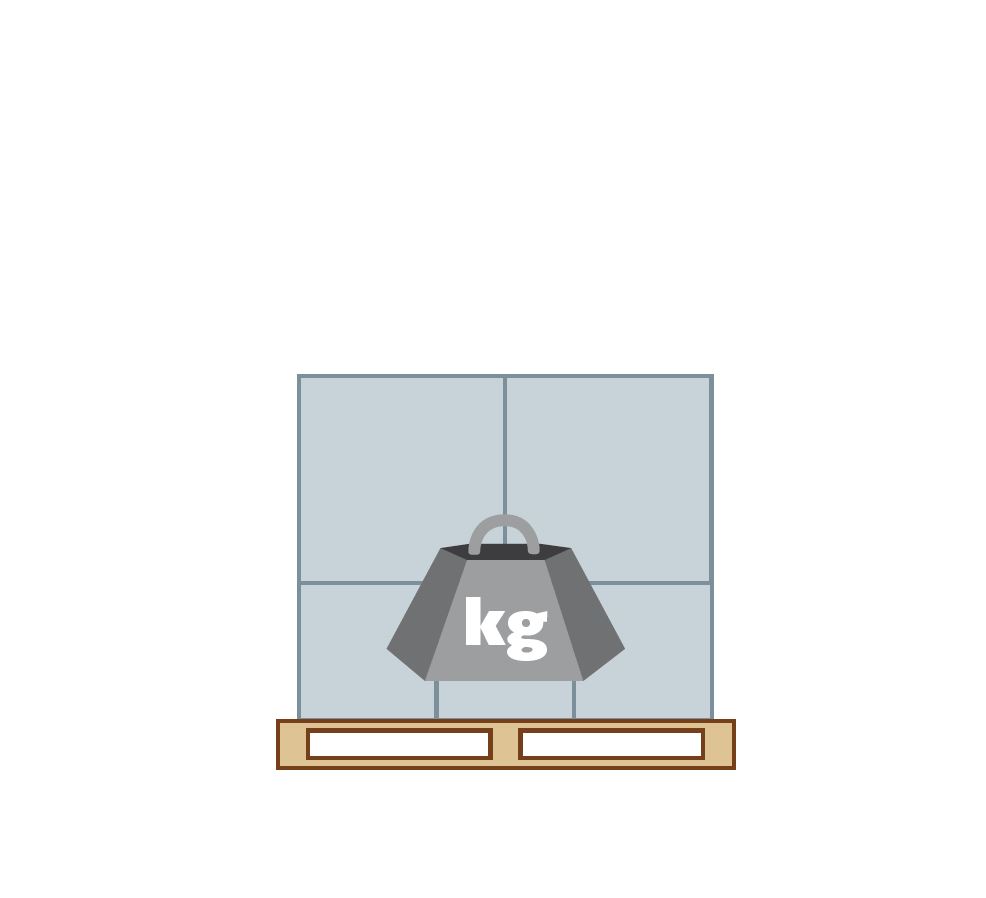

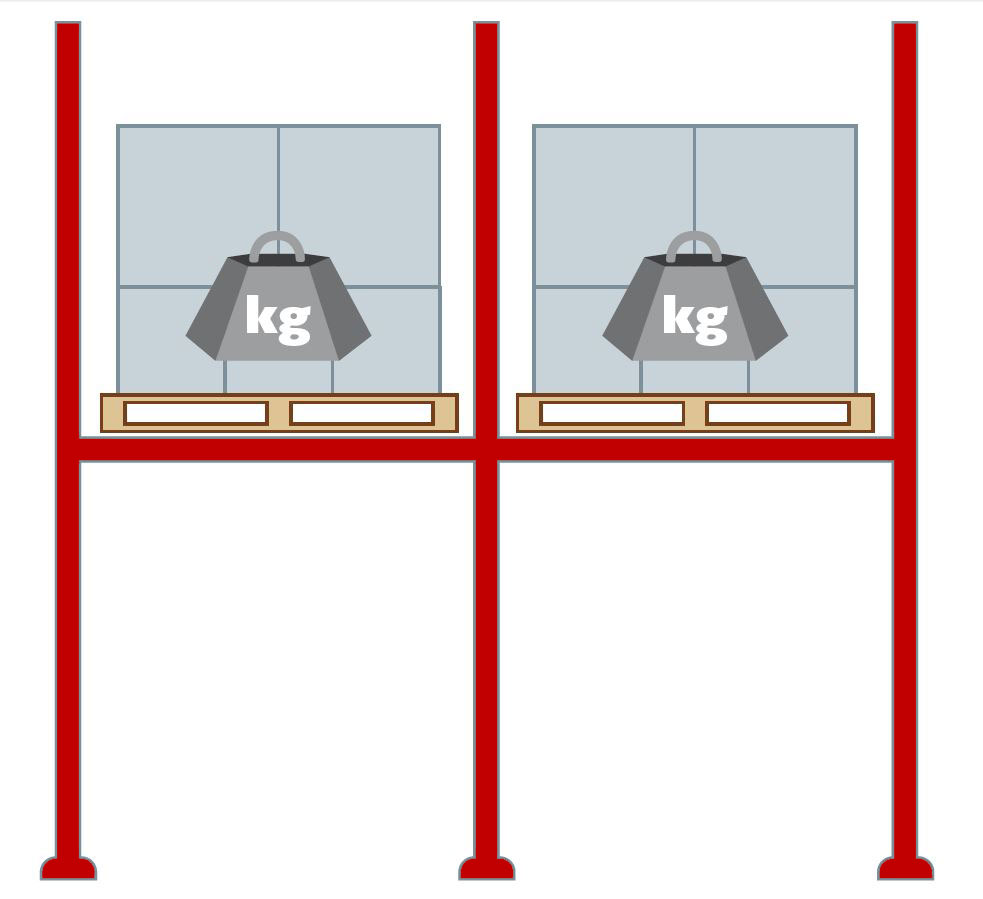

Carrying capacity is undoubtedly one of the most important features in choosing a pallet. The carrying capacity depends a lot on what you want to do with your pallet. A distinction is usually made between three situations:

| Static load | Dynamic load | Load in a rack |

|

|

|

| Maximum load a pallet can support when stationary on the ground . | Maximum load a pallet can carry in motion. | Maximum load a pallet can carry if the two longest sides rest in a rack. |

3. What materials are pallets made of?

Pallets are made of one of these four materials, each with its own advantages:

All these materials have a few important characteristics in common. For instance, they are perfectly nestable (if they are the same size). So by putting them on top of each other, you gain a lot of space when storing them. Secondly, almost all RAJA pallets are suitable for export. They allow you to safely transport your goods to all corners of the world. Furthermore, pallets made of wood fibre, cardboard and plastic no longer require anti-parasite treatment (they therefore automatically meet the ISPM15 standard). Wooden pallets still need a special heat treatment before they meet the ISPM15 standard. A wooden pallet is afterwards marked with the symbol of an ear of corn as seen here.

Wood fibre pallet |

. – Economical: they are the cheapest pallet solution. – Safe to use : they contain no nails, splinters or sharp corners. The closed bottom means your goods are better protected against rising moisture and splashing dirt. – Resistant to temperatures from -65 to +120 °C. – Suitable for export and recyclable. |

| Wooden pallet* .  |

. – Robust: perfectly stabilise your load and can handle a high load capacity (up to 4000 kg in static storage). –Naturally non-slip: suitable for all business sectors and storage applications. – Suitable for export if they meet the ISPM15 standard. The wood underwent treatment for this purpose, making it interchangeable around the world. – Recyclable. |

| Cardboard pallet .  |

. – Very light: this variant weighs by far the least. And you know: the lighter your pallet, the lower your total shipping costs. – Save time: cardboard pallets from RAJA are equipped with a notch at the bottom that allows you to quickly secure the stretch film during manual wrapping. – Suitable for export and recyclable, just like a cardboard box. |

| Plastic pallet .  |

. – Hygienic and washable: can be cleaned with water. – High load capacity: they can carry the highest load of all types of pallets, up to 7500 kg in static storage. – Sustainable: they can be reused very often, thus reducing the use of raw materials. – Suitable for export and recyclable. |

* Within the wooden pallet family, there are both ‘disposable pallets‘ and ‘exchange pallets‘. The disposable version is cheaper, less strong and should be destroyed after receipt for hygiene reasons. The swap pallet is sturdier in shape and is more often sent back and forth between different destinations.

]4. How do you prepare a pallet for transport?

Have you found the pallet that best suits your use? Then now follow these tips to stack your goods optimally and ship your pallet safely:

- Never place your boxes over the edge of the pallet.

- Always place your heaviest boxes at the bottom. Are there no big differences in weight? Then place your smallest boxes at the bottom and the largest at the top.

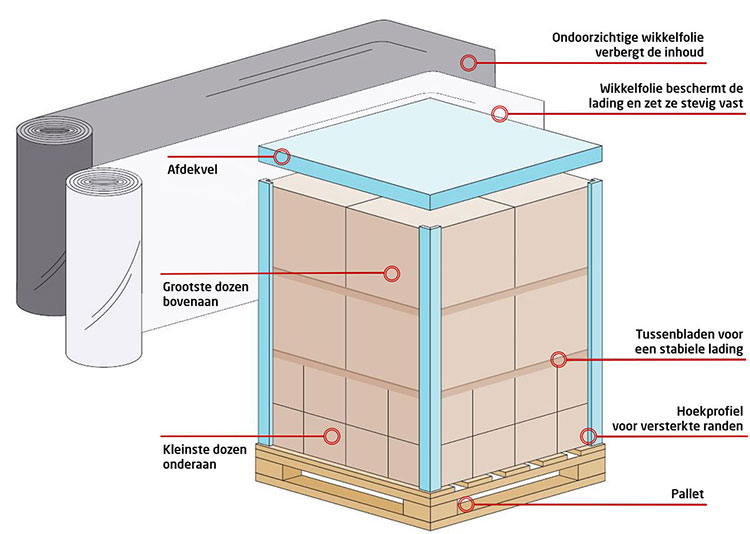

- Protect your stacked boxes with dividers, corner profiles or cover sheets.

- Choose wooden pallets that comply with the ISPM15 standard. Pallets made of wood fibre, cardboard and plastic do not need additional treatment for export.

- Wrap your entire pallet with wrapping film. This will protect your goods from water, dust or shifting.

5. How should you wrap a pallet? Manually or mechanically?

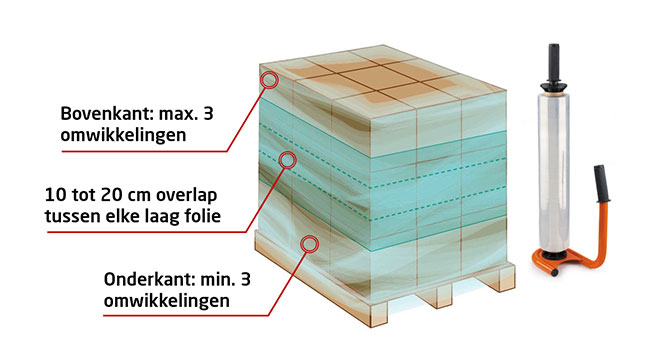

After you have loaded your pallet with goods, it is important to wrap the whole thing with stretch film. This ensures greater stability of your load, your goods are better protected against moisture, among other things, and your pallets can be loaded more smoothly into trucks and containers, for example. Check here which technique is best when wrapping your pallet.

► Manual wrapping

This technique will require your employee to walk around the pallet with a film unwinder. However, the physical effort required for this can be quite tiring after a while. Moreover, a human can often not match the accuracy of a machine.

Although manual wrapping has some limitations, it is still the most commonly used technique in small businesses or companies that process a limited number of pallets per day.

► Machine wrapping

To wrap your pallets easier and faster, you can use a film wrapper. It constitutes the best solution when you wrap more than 15 pallets per day. However, your pallet, including load, should not exceed 2 metres in height. A film wrapper adapts perfectly to the shape of your pallet and load. As a result, your pallets are wrapped more stably and with an ideal amount of film: never too much and never too little. There are machines available that can handle up to 250 pallets per day. So that equals a boost to your time savings and productivity.

Manual wrapping takes much more time than machine wrapping. On average, it takes a wrapper about 15 minutes to correctly wrap a pallet. With a machine, it only takes a fraction of that time.