In this selection guide, we highlight two types of rolling warehouse equipment: rolling containers and shelf trolleys. Besides their wheels, they have quite a few other things in common, it turns out… For many warehouse operators, they are an indispensable tool for moving a large quantity of boxes or bins in one movement. Ideal to save time and space. Which trolley or roller container will do the job for you? Check out all the options here.

1. Tiered trolley or roll cage: which will it be?

► Shelved trolley

A shelf trolley is basically an upgraded version of a platform trolley. However, a shelf trolley is much higher, giving you more shelves. Ideal if your warehouse worker wants to move a lot of boxes or bins at once. They are mainly used in an internal transport chain, i.e. within the same warehouse. There are also shelved trolleys with tilting shelves (up to 15°): this makes loading and unloading even easier. Finally, there are versions with a grid around the frame. These ensure that your goods cannot fall off. This last variant already closely resembles what we call a ‘roll container’.

Standard model |

With tilting shelves |

With closed sides |

| (1) Wheels with brake (2 ) Push bar |

(1) Wheels and central foot brake (2 ) Push bar (3) Tilting shelves |

(1) Wheels with brake (4) Choice of model with 2 or 3 side walls + roof and door |

| Total load < 600 kg | Total load < 400 kg | Total load < 500 kg |

| L 100 x W 60 x H 155.2 cm | L 180.5 x W 65 x H 185.5 cm | L 123 x W 62 x H 147.5 cm |

| 4 or 5 wooden shelves (max. load 90 kg) |

4 wooden shelves (max. load 80 kg) |

Optional shelves (max. load 80 kg) |

| Tube frame in welded steel | Tube frame in welded steel | Tube frame in welded steel |

► Roller container

What about a rolling cart? This rolling equipment is characterised by two things: on the one hand, you have the metal side panels around the cart. These ensure that there is less risk of your parcels, boxes or bins falling off the container. On the other hand, there is the fact that the entire container is made of galvanised steel. This steel is resistant to corrosion/rust and can therefore be used both indoors and outdoors. Ideal for external transport, e.g. by truck. Good to know: roll containers are also often used without a shelf. This makes it much easier to move bulky goods. Large boxes that you cannot slide between two shelves are therefore not an obstacle.

Standard volume |

Large volume |

Anti-theft |

| With tension strap to hold products | With extra-large storage space | With mesh roof and door (padlock optional) for locking |

| Total load up to 500 kg | Total load up to 500 kg | Total load up to 500 kg |

| L 72.5 x W 80.5 x H 188 cm | L 120 x W 80 x H 192 cm | L 71.5 x W 80.5 x H 192 cm |

| Shelves optional (max. load 150 kg) |

Optional shelves (max. load 150 kg) |

Optional shelves (max. load 150 kg) |

| Galvanised steel frame | Galvanised steel frame | Galvanised steel frame |

2. Advantages and use

► Easy to move

A first advantage of shelf trolleys and roll containers lies in their manoeuvrability. They are fitted with 2 fixed wheels and 2 swivel castors as standard. So you can easily roll them everywhere along, between, through and under. If you put them side by side, they also fit perfectly in the cargo hold of a truck.

Tip: it is better to push rather than pull the roll container. Pushing is much easier, safer and less stressful for your back.

► Reliable

This rolling material is made based on a strong steel frame. So you can rest assured that your products are well protected from knocks. Unlike, say, a pump truck, nothing is motorised either. So it requires less maintenance.

► Safe

The ‘safety’ aspect is particularly important with roll containers. The metal cage structure keeps your goods or stackable containers in place. Especially if you choose a container with 4 walls: there is no longer any risk of your goods tumbling out of the container. If you work with pricey products, choose an ‘anti-theft’ roll container with a lockable door. All you need then is a padlock. This way, your products in your warehouse can be locked safely in a simple way. If you have a roll container with only 2 or 3 walls, you can alternatively wrap and seal it completely using wrapping film. Simple yet effective!

Tip: always place the heaviest goods at the bottom. That way, you maintain maximum stability of your rolling stock.

]3. Accessories for roll containers

With the extras below, you can get even more out of your roll cage. As a one-stop shop, RAJA is the perfect place to buy all your warehouse supplies in one go: cheaper, easier and faster!

- [1] Document covers & labels: this is how to easily identify your container load.

- [2] Straps: this secures a load securely.

- [3] Extra shelves: makes even better use of the available space inside the roll container.

- [4] Padlocks: completely seals a roll container with 4 sides for extra security. Containers with open sides can be wrapped with stretch film for protection.

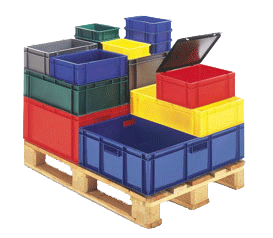

In many logistics centres and warehouses, both trolleys and roll cages are combined with stacking bins. These stacking bins allow you to move a much larger quantity of small products in one movement. Handy, isn’t it? The bins below are compatible with RAJA’s shelf trolleys and roll containers:

| Euronorm stackable box* Stackable and palletisable  |

Euronorm stackable box with fixed lid Store your products safely  |

Euronorm stacking bin with perforated sides Avoid moisture  |

| Euronorm stacking bin in 5 colours The largest choice of models  |

. . . |

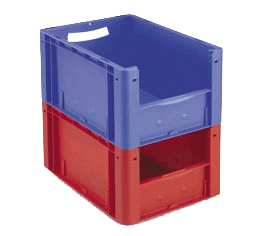

Euronorm stacking bin with grab opening For faster order picking  |

| Courier box Ideal for internal transport 100% space utilisation  |

Folding crate Foldable for more space saving after use  |

Multipurpose plastic box Stackable and hermetically lockable**  |

* All bins marked ‘Euronorm’ comply with standard dimensions and can be combined with each other.

** Please note: product code 145C is not suitable for all types of rolling containers or shelf trolleys in this article.