Polishing: a necessary evil? Not at all! With the right cleaning paper in hand, everything goes a lot smoother. This selection guide gives you an overview of the most important differences and properties of cleaning paper (and their dispensers). Make your choice below and leave no stain untouched. Besides cleaning paper, there are a few other cleaning materials that are indispensable in an office or warehouse. Just think of cleaning cloths and paper towels. You can read all about them in our next article.

Cleaning paper: spotless from head to toe

Cleaning paper is one of the most versatile cleaning materials. You can use the basic variants for wiping your hands or absorbing liquids. The thicker variants serve mainly for industrial applications. For example, for wiping mechanical parts.

The following four properties of cleaning paper determine your choice:

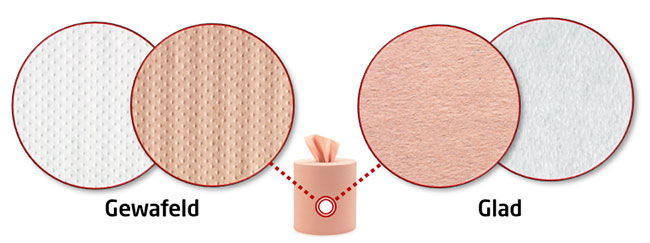

► 1. Waffled or smooth?

The surface of polishing paper can be waffled or smooth. A waffled texture is ideal for picking up stubborn stains and firmer wiping. A smooth layer is recommended for use on delicate surfaces.

► 2. Central or lateral settlement?

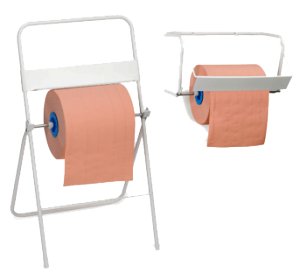

Cleaning paper is usually sold in rolls. That roll has either central or lateral unwinding. With central unw inding, you unroll the paper from the core. When you use the roll for the first time, this requires you to pull a cardboard tube out of the roll’s core. With central unwinding, a wall dispenser comes in handy.

When unrolling sideways, you unroll the paper along the outside. For this, you need a horizontal stand (which you can attach to the wall if necessary). So keep in mind the type of unwinding as this will determine the unwinder you need to use.

► 3. WS treatment or Quick Dry?

Polishing paper may have undergone a WS treatment (which stands for Water Strengthening). This makes the paper still very strong even when wet and less likely to tear. In addition, cleaning paper can also carry a Quick Dry label (from Tork®). This means that the paper can absorb a greater amount of moisture. The higher the absorbency, the less paper you need to use, and thus the more you save on it.

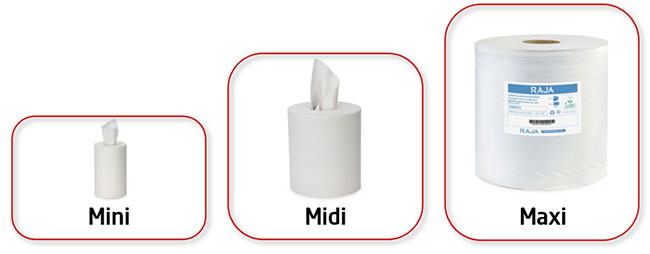

► 4. Mini, midi or maxi?

-

Mini rolls are the smallest variant and are often used in locations where there is no space to install a larger-sized dispenser (e.g. a compact toilet). They usually have the same height as a midi roll but are less thick (and therefore contain fewer sheets of paper).

-

Midi rolls are the middle size. People use them in a wide variety of environments.

-

Maxi rolls are very large rolls, intended for use in a wide industrial environment. You will need a suitable dispenser for this, usually a horizontal floor stand.

With the above info in mind, it’s time to put our cleaning paper into an overview. We start with the softer models, then switch to the universal rolls and finish with the strongest variants.

| Cleaning paper |

Application |

Properties |

Roll holder |

Soft* |

– To absorb small amounts of liquid. – For wiping hands. – For cleaning glass. |

– 1 layer per sheet.* – In mini or midi rolls. – Smooth paper. – Ecolabel. |

. |

Standard  |

– For thoroughly polishing slightly more delicate surfaces. – Easily picks up the smallest dirt. |

– 2 layers per sheet. – In maxi rolls. – Waffled or smooth. – WS-treatment. – Ecolabel. |

. |

All-round |

– For general cleaning in garages, storage areas or workshops. – Feels like a chamois sheet. |

– 2 layers per sheet. – In maxi rolls. – Waffled or smooth. – WS treatment. – Ecolabel. |

. |

Strong** |

– Ideal for wiping up liquids. – Against stubborn stains. – Tear-resistant and very thick: protects your hands. |

– 2 layers per sheet. – In maxi rolls. – Wafeled paper. – Quick Dry. |

. |

Ultra-strong  |

– Removes oil and lubricant. For stainless steel and stainless steel. – Protects hands from metal shavings and heat. – With soft side that leaves no streaks. |

– 3 layers per sheet. – In maxi rolls. – Wafeled paper. – Quick Dry. |

. |

* Also available in a variant with 2 layers of paper for even greater absorbency.

** The blue variant is used in the food processing industry, among others. If the paper accidentally ends up among food, its blue colour is more noticeable than white (see HACCP standards).