Cargo securing: that’s securing your cargo securely in a truck. That might seem obvious… Yet every year, deliveries are still damaged by cargo that was sliding. It is not just an empty term but the basis of a lot of rules (laid down in Dutch Traffic Legislation and European EUMOS legislation, among others). We summarise the main points of that legislation for you below and take a look at the most popular tools.

1. What methods of cargo securing are there?

Keeping your load from sliding or toppling over can be done in two ways: via a force closure or a form closure.

A force closure involves securing your load by applying vertical force to the floor. You ‘push’ the load downwards, as it were. You can do this by using tension straps, for example. A clean loading floor is really recommended for this. Dirt can interfere with friction. To increase friction, you can, for instance, use anti-slip strips for pallets.

With a moulded closure, your load is ‘locked in’. Friction is therefore not (or less) involved here. Your load is, as it were, blocked and has no room to take on a life of its own. You can do this by loading your truck optimally full and by filling any empty spaces with ‘pads’.

]2. What means do you use to secure your cargo?

| Pallets .  |

Pallets are absolutely essential for stable loading and safe transport. They are the first step of your load securing. Pallets – and especially the wooden variants – create higher friction with the floor. As a result, your load will not slide as much. Moreover, they always guarantee that your load rests on a stable base. Want to know more? Take a look at our selection guide for pallets. |

| Stretch film .  |

Once stacked on a pallet, your loose goods need to be stably secured into a homogeneous whole. Stretch film will support you both literally and figuratively. Thanks to stretch film, your cargo remains much more stable and suffers less from bumpy transport. And another handy extra: the plastic film protects your cargo from dirt, dust and rain. Want to know more? Check out our selection guide for stretch film. |

Strapping straps |

If your goods are too large or heavy for stretch film, try using strapping. Especially the steel variants have a very high tensile strength. You simply wrap such a steel strap around your goods and then tighten it with a strap tensioner. Even your heaviest loads will remain one piece this way. |

Straps |

Use lashing straps to firmly secure a fully loaded pallet. This creates more force and friction relative to the floor. As a result, your pallets are significantly less likely to shift. In addition to pallets, lashing straps also come in handy when securing very large goods. |

Anti-slip sheets |

Are your goods stacked in layers on your pallet (e.g. stacked boxes)? Then provide a sheet with an anti-slip coating between each layer. With a slight angle of inclination (up to 42°), you will have much less chance of your load sliding. |

Corner profiles |

A cardboard corner profile is placed at the corners of your cargo. They guarantee more stability and protect your load from being cut by a strapping or tensioning strap. Moreover, they ensure that the tension of such straps is evenly distributed. |

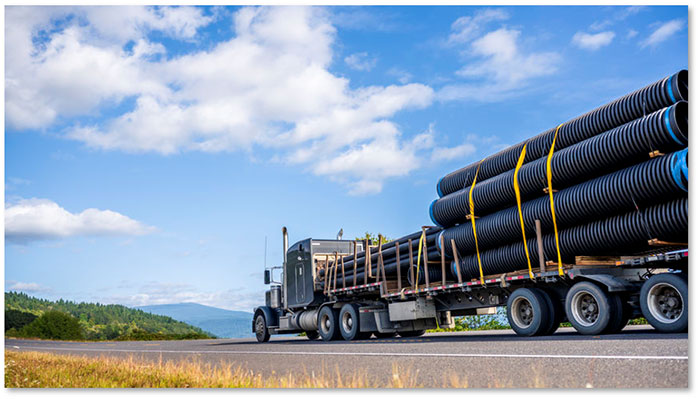

Roll stopper |

Are you transporting cylindrical objects? Then use a roll stopper to prevent your products from rolling. Extra plus: roll-stoppers are very light and nestable, which reduces storage and shipping costs. |

Foam sheets and cushions |

Foamplates and cushions are used inside a box to better secure loose products. Products that are too loose in a box can easily shift. If you multiply that movement by 10 or 100 packages, your entire pallet load will become unstable and threaten to tip over. So be sure not to forget the inside of your boxes! |

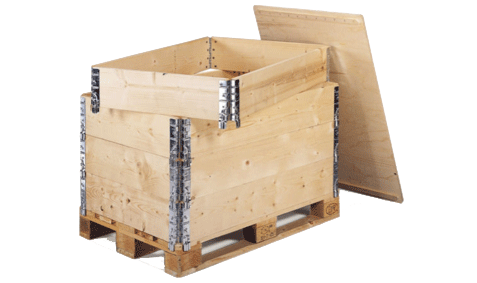

Collars |

Collars are used for loading heavy or bulky goods. You place them on top of a pallet base. In no time at all you create homogenous and stable boxes that you can transport much more safely. |

3. What legislation applies to load securing?

First, let’s stop at the EUMOS legislation: it has been in force on all European roads since 2014. It is a kind of guideline to ensure load securing in road transport. Some countries, such as Belgium, have adopted these rules in their legislation. The Netherlands, however, has specific guidelines. These are laid down in the Traffic Act (see art. 5.18.6). The two main guidelines therein are the following:

- The load or parts thereof must be secured so that they cannot fall off the vehicle under normal traffic conditions, including full braking, sudden evasive manoeuvres and bad road surface.

- Loose cargo in respect of which there is a risk of it or parts thereof falling from the vehicle while driving shall be securely covered.

4. How is load securing checked?

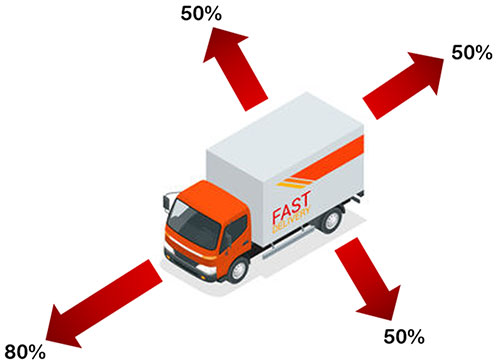

Should your cargo be officially inspected in Europe, they will mainly look at how your cargo is secured. What is important here is that your cargo securing must be able to withstand certain forces during transport. In normal traffic, the following forces occur:

- In the driving direction = 0.8 G = corresponds to 80% of the load weight,

- In the rearward direction = 0.5 G = corresponds to 50% of the load weight,

- To both sides = 0.5 G = corresponds to 50% of the load weight.

In other words, when your driver applies the brakes fully, your cargo securing must absorb 80% of the load weight in the driving direction and 50% in the sideways and backwards direction.

Moreover, any means you have used to secure your load must meet a number of conditions. These means must be in perfect condition and serve what they are used for. Cracks, cuts, fraying or damage are therefore absolutely not allowed. Furthermore, they must conform to European and International product standards.

5. An accident? Who bears the responsibility?

Since the introduction of the EUMOS legislation, several parties in Europe can be responsible in an accident, not just the transport company. The responsible parties can be divided into five categories.

| . 1. Driver |

The driver transporting the load in question should carry out some checks before leaving. The driver may be held partly liable if these checks were not carried out. A driver must always:

|

| . 2. Carrier |

He is responsible to provide proper documentation to the competent authorities. Unless the carrier has a special arrangement with another party. The carrier must:

|

| . 3. Shipper |

The sender ensures that the carrier receives the correct data so that the carrier can pass it on to control authorities. These data are:

|

| . 4. Packer |

The packer must prepare a description of the goods. For example, if the goods may be damaged by the straps, the packer must describe an alternative method of securing these goods. Special requirements for the vehicle should be mentioned by this party in the method. |

| . 5. Shipper |

The shipper ensures that the cargo is properly distributed on the loading floor. He ensures that the goods are loaded and safely secured. The shipper ensures that the MTM (maximum authorised mass) and axle loads are respected. The shipper must provide the following information:

|