Shipping five parcels… Or shipping five hundred parcels? That makes a significant difference to how you allocate your time and manage your costs. Machines that automatically pack are then an efficient solution in many cases. They come in all shapes and sizes, so there is something for everyone! So what does automation really mean and what could be the benefit for you?

1. Automatic packaging: always precise and fast

With a fully automated machine, you as a human being no longer have to intervene. Such a machine allows automatic packaging to proceed of its own accord.

| Advantages |

Disadvantages |

| ► It increases productivity: your employees can perform other useful tasks simultaneously.

► It reduces stress: the machine rarely makes mistakes and relieves your employees of the pressure of responsibility. ► It increases the quality of your packaging: they all meet the same standards. ► A machine never consumes more packaging material than is strictly necessary. So you have to buy less material. |

► However small, there is a risk of technical failure. Regular maintenance is therefore necessary.

► Machines require a higher (one-off) investment. |

For a lot of steps in your logistics process, you can opt for an automated solution, some a bit bigger than others. Together, they ensure that your orders are prepared much faster and more accurately.

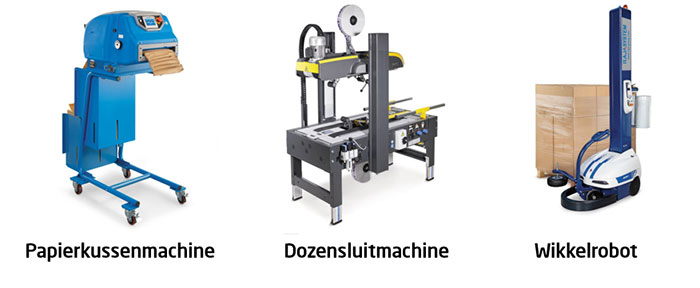

Common examples are machines for making filling paper or air film. With these, there are models that automatically make a new load of padding material as soon as your stock runs out. Automation can go a step further, for example with a carton sealer (which you integrate on a roller conveyor) or a wrapping robot (for wrapping pallets).

In the video below, we show you exactly how such a wrapping robot works:

Did you know… you can simply rent many of these machines? So ideal for smaller or start-up businesses! For more info, call us on 0800-225 25 25.

Did you know… you can simply rent many of these machines? So ideal for smaller or start-up businesses! For more info, call us on 0800-225 25 25.

2. Semiautomatic packaging: between man and machine

In the semi- or semi-automatic method, a human controls the machine. Without his control and regular intervention, the machine will not be able to perform the work process correctly.

| Advantages |

Disadvantages |

| ► It improves your employees ‘ productivity.

► It increases the quality and smooth processing of your orders. ► It becomes easier to pack or transport medium volumes and quantities. |

► No matter how small, there is a risk of technical failure. Regular maintenance is therefore necessary.

► Machines require a higher (one-off) investment. |

Semiautomatic devices require a (regular) presence of one of your employees. There are solutions for filling, sealing or wrapping your parcels. The automatic paper cushion and air cushion machines we discussed above can also be operated semi-automatically. You then do this via a control panel or a foot pedal. This puts you in control of the amount of padding produced.

Other examples are semi-automatic strapping machines or shrink wrap machines. An operator has to hand over the products each time and will make sure that everything is handled properly. However, the machine does all the heavy lifting for him.

3. Manual: take the reins yourself

Since a machine won’t fit just anywhere, we’ll give another word on manual packing. So we leave the machines for a moment and show you some options that will come in handy at any packing table.

| Advantages |

Disadvantages |

| ► You are not dependent on technical failures.

► You can highlight the professionalism of your employees. ► It is the most economical solution for starters. |

► Repetitive work can lead to mistakes.

► Manual packing can be a physical strain for your employees. |

With so-called ‘smart packaging’, you can often work significantly faster. Such smart packaging has intuitive extras that require your packer to perform fewer operations at the packing table. The examples below are often used in e-commerce, among others:

-

[1] Box with automatic bottom: by pressing the side walls, this box automatically folds into the right shape. Your box is ready for use 2.5 times faster, and with a solid bottom.…

-

[2] Box or mailing bag with integrated closing strip: another solution for eliminating a number of operations is a closing strip. No more need for a tape or dispenser.

-

[3] Box or shipping bag with integrated filling material: there are packages in which the protective material is already included. Examples are bags with bubble wrap on the inside, or boxes with foam or fixer film. That kind of solution is often used when packing clothes, fashion accessories or cosmetics.