Today we are talking about one of the protagonists of the packaging world, indispensable if you need to secure and protect your pallets: stretch film.

Stretch film is a plastic, resistant and elastic film used for pallets, heavy and bulky objects, but also fragile and delicate ones.

Which one should you choose to make sure your pallets are best protected?

Questions you must ask yourself before choosing stretch film

- What type of products do I need to protect?

- Are my goods sensitive to compression? Is it likely to warp, expand or shrink?

- What is the weight of the pallet?

- Is the pallet regular in shape or irregular with protruding corners?

- Do I already use theft protection?

- How many pallets should I film per day?

The answers to these questions will determine your choice!

Which stretch film to choose

The colour of stretch film

- White or matt black film guarantees maximum discretion. Protecting pallets with black film means perfectly concealing the contents of the pallet and not drawing attention to what is stored. This trick is very useful for more expensive products.

- The black film also protects the products against UV radiation.

- The transparent film: protects the pallets by allowing the goods to be visible; this is useful for reading barcodes and any accompanying documents.

- The coloured film: available in various colours (red, green, yellow and blue), it allows you to easily distinguish and recognise your pallets. Great for managing different workflows.

The quality of stretch film

- 3-layer cast stretch film: very elastic and resistant, it is made of 3-layer cast polyethylene and allows good pallet retention during transport or storage. Perfect for palletising objects with protruding corners.

- Pre-stretched film: durable and economical, as it is already pre-stretched on both sides, it can be applied effortlessly. Compared to a traditional film, it uses 20 to 30% less material to cover the same surface area and generates half the waste.

Manual or automatic filming?

Stretch film can be stretched manually or automatically using wrapping machines.

Manual filming

This type of film is made by unwinding the film using a manual dispenser and wrapping the pallet. It starts at the bottom and proceeds upwards where the film is then fixed.

Mini stretch film reel

For pre-palletising, wrapping flexible products, protecting surfaces from dirt and grouping long products, choose mini reels. They are super handy and practical!

Automatic filming

Automatic filming requires less physical effort, is more efficient and is ideal for intensive use.

It can be done with different machines:

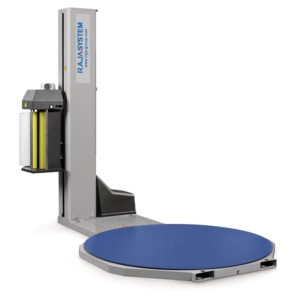

- Rotary table wrapping machine: with mechanical brake or motorised pre-stretching, this machine is suitable for filming standard-sized pallets. Perfect for wrapping regular and not very fragile loads.

Depending on the company’s needs, different models are available:

To film up to 150 pallets per day, you can choose a machine with a manual brake.

To prepare up to 250 pallets per day the one with motorised pre-stretching to maximise productivity.

- Rotary arm wrapping machine:

Hooked to one of the pallet corners, the table rotates the arm that wraps the film around the pallet. It enables full automatic palletising and only requires the knot to be cut at the top once the operation is complete. This wrapping machine is multi-purpose: it covers 100% of film wrapping requirements (homogeneous pallets or sharp corners, heavy and non-heavy loads, products sensitive to stacking). Automatic and programmable, it requires almost no human intervention. This machine needs a fixed area to perform palletising: it can film up to 250 pallets per day.

- Self-propelled wrapping robot: intuitive, easy to use and space-saving. This robot is perfect for unstable, light and irregular pallets. It wraps your pallets autonomously.

In summary:

- ask yourself the right questions before choosing your stretch film: weight, shape, pallet protection, etc…

- choose stretch film in relation to manual or automatic filming.

- choose the quality of the film in relation to the products, the pallet and the type of use: stability or visual recognition?