Optimising warehouse space and improving operational efficiency are key goals for every company. Did you know that pallet boxes and palletisable boxes can be strategic allies in achieving these goals?

In this article, we will discuss the distinctive features and advantages of each solution, helping you to make the right choice for your business.

How to distinguish between a pallet box and a palletisable box?

Don’t let the name fool you, pallet boxes and palletisable boxes are not always the same thing. Let’s find out what the main differences are right now:

Pallet boxes

These boxes, also called Palboxes, are specifically designed to fit standard pallet dimensions. This means that they are exactly the same size as the pallet on which we are going to place them. They are made with dimensions and strength to optimise the space on the pallet and ensure stability during transport and handling.

The pallet boxes or container boxes are usually made of strong materials such as reinforced double-wave cardboard to withstand heavy loads and often have features that facilitate their use, such as lids, flaps or special openings. They are designed to be placed directly on the base of pallets, ensuring that the size of the box exploits the entire surface of the pallet without protruding or creating instability. Also included in this category are the pallet crates, very strong wooden crates perfect for export.

Pallet boxes

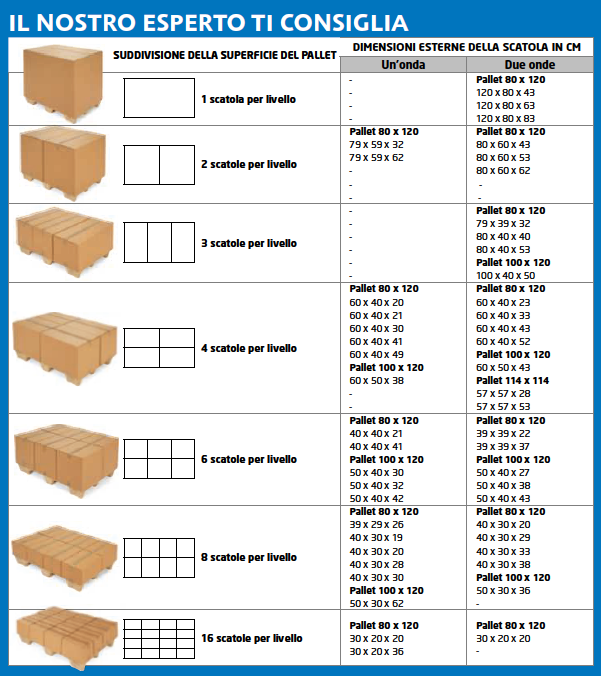

The term‘palletisable boxes‘ is a bit more generic and refers to any box whose size or multiple thereof can cover the entire surface area of a pallet. To put it another way, palletisable boxes are made to standard external dimensions that correspond to sub-multiples of the dimensions of a pallet. Pallet boxes are therefore always pallet boxes but pallet boxes are not always pallet boxes.

Pallet boxes are therefore usually smaller than pallet boxes but are sturdy enough to be stacked and placed on a pallet.

How to choose the box for your pallets?

The choice between pallet boxes and palletisable boxes will depend on the specific application, logistical needs, and the importance of optimising space and load stability during transport and handling in the warehouse.

- Dimensions: Pallet boxes are designed with specific dimensions and characteristics to perfectly fit pallets, while palletisable boxes can be of different dimensions, again in line with the concept expressed above. It goes without saying that if the product you have to ship is small or medium-small, your choice will fall on palletisable boxes.

- Space optimisation: pallet boxes are optimised to maximise space and stability on the pallet, reducing the risk of the load moving or tipping over. With one large box you are sure to cover the entire surface.

- Versatility: pallet boxes offer more versatility in terms of size and use. They range from 30 to 80 cm wide, are available in one-wave or two-wave and can therefore be adapted to many types of products.

What is palletising?

Palletising is a crucial procedure in the logistics sector that involves stacking and organising goods on a pallet, a load-bearing platform that facilitates the lifting and transport of heavy loads with the help of a forklift or pallet truck.

This method is key to maximising warehouse efficiency, making the best use of available space and minimising the risk of accidents.

Advantages of palletising

- Space optimisation: stacking goods on pallets allows vertical utilisation of warehouse space, increasing storage capacity.

- Safety: correct palletisation reduces the risk of products falling or being damaged, guaranteeing the stability of the load unit.

- Operational efficiency: by facilitating the handling of goods, palletisation reduces loading and unloading times, increasing worker productivity.

- Standardisation: the use of standardised pallets facilitates the handling and storage of loads, as well as allowing better use of space in transport vehicles.

Best Practice in Palletisation

- Pallet selection: it is essential to select the most suitable type of pallet according to the size, weight and type of goods to be transported. You can choose between a pressed wood, cardboard or plastic pallet, but the important thing is to check its dynamic load. If you have any doubts about choosing a pallet , read our article How to choose the right pallet for your storage, logistics and transport needs?

- Arrangementof goods: boxes or products should be arranged to maximise load stability, following patterns that may vary according to the size and shape of the units. As a general rule , we advise you to place the smaller boxes on the base of the pallet and the larger boxes on top; this will help you to have a better support base.

- Use offixing materials: the use of stretch film, strapping or other fixing materials helps to keep the load stable and protected during handling. Without adequate external fixing, the boxes would move during transport.

Tips for perfect palletising

- A box is considered ‘palletisable’ if its dimensions allow it to be placed on a pallet without protruding beyond the edges.

- Incorrect palletisation can reduce the vertical compression strength of boxes by up to 80%.

- By stacking two boxes, the maximum supportable load for each is halved.

- Remember the importance of the compatibility of the dimensions of the boxes with those of the pallet, to avoid overhangs or gaps that could compromise the stability of the entire load unit.

Did you know that palletisation can also be advantageous when buying your own packaging? By choosing to purchase an entire pallet, you can take advantage of discounts for large quantities and simplify the verification process for your operators when receiving goods.

A full pallet of goods is more advantageous for both the shipper and the buyer!

Palletising is a key aspect of logistics that, if done correctly, can lead to significant improvements in efficiency, safety and space optimisation in a warehouse!