What is the best packaging solution for your company? What are the advantages of introducing a machine and when is it really worth it?

What are the existing solutions for your packaging process?

Products can be packaged in different ways. To help you choose the best solution for your company, here is a list of the different methods and their advantages and disadvantages.

The manual solution

You can of course choose to pack without using machines. The procedure is slower, but enhances the work of your employees.

However, you must not forget that man is not a machine and that repetitive tasks can lead to errors.

What are the possible disadvantages of the manual solution?

- Physical problems for your employees;

- Mistakes in the packaging process;

- Repetitive and effort-intensive work.

Errors due to fatigue, the slowness of the manual process and physical pains could take their toll on your company.

What is the advantage of doing everything manually? The work does not depend on machines and is therefore not affected by their potential failures. Even if the risk is reduced, it is still a possibility.

A work stoppage (which in 87% of cases is due to Musculoskeletal Disorders, MSDs) results in slowdowns. However, these slowdowns are minor compared to those that would occur in the case of a machine failure.

The semi-automatic solution

What are the advantages of a semi-automatic solution?

- Improves the work efficiency of your employees;

- Greatly reduces the risk of musculoskeletal disorders;

- Improves the final quality of your packaging

Choosing a semi-automatic solution means implementing systems that need human intervention to be started.

This is the case with the semi-automatic winding machine (manual brake winder):

By choosing it you limit the risks of musculoskeletal disorders for your employees and speed up the preparation of orders.

We recommend the use of a semi-automatic wrapping machine if you prepare at least 10 pallets per day.

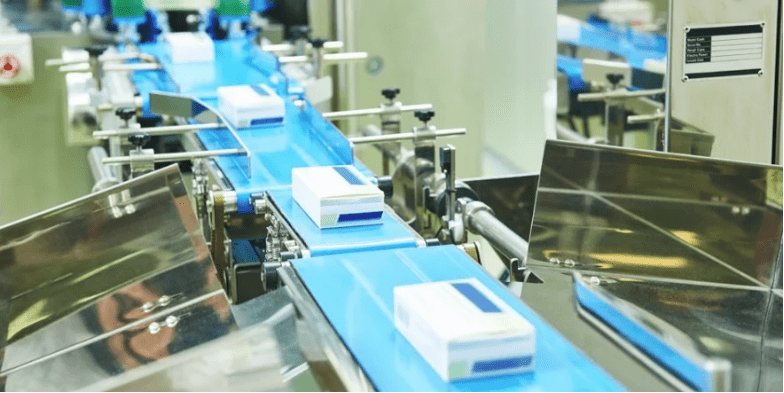

The automatic solution

Rotary arm wrapping machine

What are the advantages of an automated solution?

- Less stress for your employees: the machine reduces errors and, consequently, the burden of staff responsibility.

- Improves the productivity of your employees who can perform other useful tasks.

- Improves well-being within the company.

By opting for this type of solution, a number of steps including, for example, closing or filming your boxes will be automated.

Machines of this type may seem expensive, but on the contrary they become profitable as soon as they can handle large order flows on a daily basis.

The more automatic the packaging procedure, the more pleasant the working environment. For what reasons?

- A good workstation improves the productivity of your employees

- Strenuous jobs are generally more dangerous and at risk of injury

Why introduce packaging machines in the warehouse?

Despite the initial investment costs, mechanising the packaging procedure in your warehouse can benefit you on several levels.

- Quality packaging: thanks to the machines, packages are uniform and well packed.

- Safety for your employees: machines reduce the risks of injuries and MSDs related to handling heavy loads and repetitive or exertion-intensive tasks.

- More storage space: some machines produce fillers on demand, thus eliminating the need to store large quantities of fillers.

Air cushion machines, for example, take up little space as the film to be inflated is delivered flat.

- Save material and standardise the amount of packaging used per pack: the machine releases the amount of filler, tape or stretch film strictly necessary to package your products.

- Youimprove the performance/effectiveness of your employees: the machine does not struggle! This allows you to have a higher pace and anticipate production peaks.

Above a certain order threshold, it becomes almost necessary to automate the packaging procedure. The advantages are numerous, ranging from the safety of your employees to the fight against waste and a gain in storage space.

In summary:

- There are 3 possible solutions for your packaging process, depending on your needs in terms of volume and speed: the manual solution, the semi-automatic solution, the 100% automatic solution.

- Mechanisation prevents the risks of MSDs and work injuries for your employees. It also frees them from strenuous operations, thus contributing to improved well-being and performance at work.

- With the machines your packaging is uniform and of better quality. Reduce the amount of packaging used.