Safety is the be-all and end-all – especially in areas where people work, move around or machines are in use. Safety in the workplace starts with clearly visible, standard-compliant safety labelling . Warning and marking tapes play a decisive role here. They provide visual orientation, increase awareness and help to prevent accidents. Safety and warning tapes are important tools for clearly marking danger zones, walkways and work areas. They are used to visually emphasise tripping hazards, slippery surfaces or machine areas and thus reduce the risk of accidents at work. They are indispensable in many industries and make a significant contribution to operational safety.

Whether in warehouses, on construction sites or in public facilities – safety and warning tapes provide clear structures and reliably indicate danger spots. In many cases, they are even required by law, as standards and regulations stipulate exactly what safety labelling must look like and where it must be affixed.

Why is visual safety labelling so important?

Visual safety labelling increases awareness of hazards and provides quick and intuitive orientation. Clear safety labelling is essential to ensure safety in the workplace and to comply with legal regulations. Colours, patterns and symbols ensure that:- Employees know at a glance where hazards exist.

- Safety areas are clearly demarcated.

- Work processes are organised more safely and efficiently.

- Unauthorised persons avoid access to hazardous areas.

- Particularly in hectic or poorly lit working environments, clearly visible safety markings are essential to avoid accidents and confusion.

Properties of safety and warning tapes

Depending on the area of application, warning tapes must fulfil different requirements. Many are made of robust PVC or hard-wearing vinyl, some are equipped with reflective or photoluminescent properties. Resistance to weathering, UV radiation or chemicals is particularly important in outdoor areas.

Another important aspect: the tapes must adhere to a wide variety of surfaces – often with anti-slip properties. Self-adhesive backings facilitate application, while special designs ensure easy removal without leaving any residue.

The right choice of tape is crucial for effective safety labelling.

Regulations and standards for safety markings

Clear rules apply to the use of warning and marking tapes. DIN and ISO standards specify how colours, symbols and sizes are to be used. Requirements for adhesive strength, slip resistance and durability are also particularly important – especially in high-traffic or sensitive areas.

The most important standards include

- DIN ISO 4844: This standard defines safety signs and warnings that are used in Germany for labelling hazardous areas. It describes symbols, shapes and colours for the clear identification of safety and hazardous situations.

- DIN EN ISO 7010: “Graphical symbols – Safety colours and safety signs”: This international standard specifies the design of safety signs for various areas of application. The aim is to ensure that safety signs are standardised worldwide. It replaces or supplements DIN ISO 4844, which is valid in Germany

- ASR A1.3 (workplace regulations): Regulates health and safety labelling in workplaces. This regulation specifies how safety markings are to be used in the workplace to clearly identify danger zones or escape routes.

- ArbSchG (Occupational Healthand Safety Act): The Occupational Health and Safety Act contains general obligations to prevent hazards and stipulates that employers must take suitable measures to prevent accidents. Safety labelling is one of these measures.

Depending on the industry, there are also specific requirements, for example in the food industry, in construction or in chemical production.

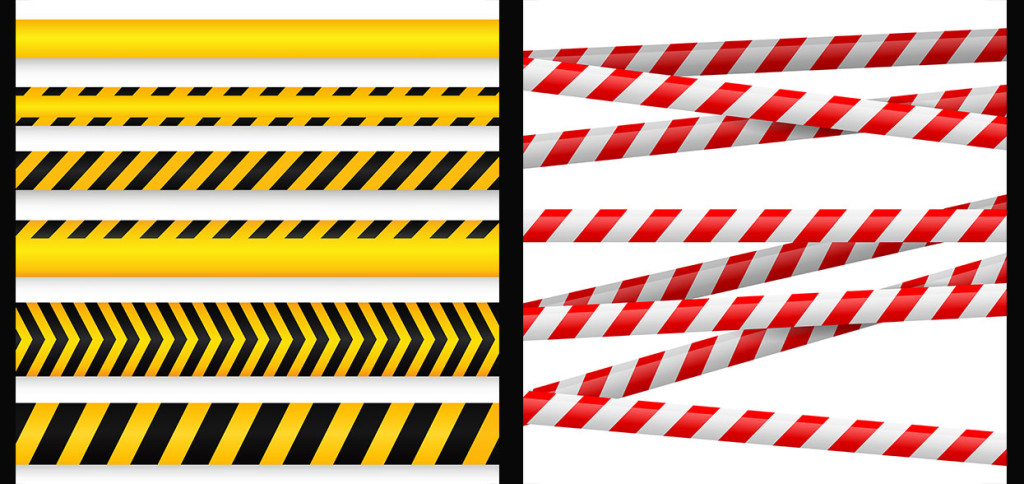

Marking of obstacles and danger points: Two-coloured

The ASR prescribes the following use so that safety markings can be recognised intuitively and there is no need for lengthy guesswork about the meaning of warning tapes, for example:

- Permanent obstacles and danger points (for example, possible falling edges such as loading ramps or the swivel range of doors) must be clearly recognisable and permanently marked with yellow and black stripes (so-called safety markings).

Temporary obstacles and danger spots (e.g. an excavation pit or similar) must be marked with red and white stripes

Marking of driveways and zones: Single-coloured

Safety markings on the floor of driveways must be marked clearly and in a clearly visible colour (single-coloured, preferably white or yellow) that contrasts as well as possible with the floor colour, in accordance with ASR. In addition, the markings must have a minimum width of 5 cm. In areas with heavy traffic, it is advisable to use marking nails or buttons for better durability – at least three per metre.

What is the significance of colours in safety labelling?

And this is what the colours mean in general:

- Red (round) = prohibition

- Red (square) = fire protection

- Blue = mandatory

- Yellow = warning

- Green = escape signs and escape routes

- Red means DANGER! RED should only be used sparingly and only in places where there is a risk of danger. Too much red will have the opposite effect of what is intended: Mindfulness decreases!

- Less is more! Always avoid an accumulation of safety signs. If the safety sign is no longer necessary, it should be removed to avoid confusion. Caution: When planning the various areas, always ensure that a maximum of 2 areas/colours are adjacent to each other. Only in this way can the meaning be understood “spontaneously”.

- In good shape! The safety markings must be checked regularly to ensure that they are clearly visible, clean and well adhered. Replace if necessary! Especially outdoors: remove leaves or snow if necessary.

- Slipping! Under certain circumstances, marking tapes can be a little more slippery than the surrounding area due to the material. To avoid this, you can use anti-slip adhesive tape or indoor marking paints.

What types of safety and warning tapes are there?

Floor marking tapes

A floor marking is a coloured safety marking or marking that is applied to the floor (painted on, stuck on…). It identifies routes or areas, for example restricted areas, parking zones, escape and rescue routes, etc. General colour codes apply; in road traffic, for example, temporary floor markings are yellow. In Germany, the installation of floor markings is regulated by the Technical Rules for Workplaces . In Austria, the Floor Markings Ordinance (Ordinance of the Federal Minister for Public Economy and Transport on Floor Markings) applies. Safety markings on the floor must fulfil high requirements in order to be durable and clearly visible in the long term. In warehouses or factory halls, it must be able to withstand being driven over by forklift trucks and cleaning machines as well as contact with water, engine oils, chemicals and many, many feet. In outdoor areas, weather influences such as UV radiation and temperature fluctuations as well as driving on with lorries weighing several tonnes must also be taken into account. In addition to special marking tapes approved for outdoor use, spray-on marking paints and special floor marking nails are also suitable for extreme conditions such as constant truck traffic.

Floor marking tape is often used in warehouses, production facilities or public buildings. They mark traffic, driving and walking routes, escape routes or danger zones and help to make storage areas and danger zones safe and guide people. As they are applied directly to the floor, they must be particularly resistant to being driven over.

Reflective and luminous warning tapes

Especially in poorly lit areas, noctilucent and reflective signalling t apes are indispensable. They mark steps, door frames, emergency exits or obstacles and ensure that important paths and areas remain clearly visible even in the dark.

Barrier and hazard tapes

They are mainly used temporarily – for example at construction sites, accident sites or events. Barrier tapes clearly signalise: No trespassing! Permanent versions are usually made of particularly tear-resistant material and are UV-resistant.

Anti-slip adhesive tapes

Stairs, ramps, wet areas – where there is a risk of slipping, anti-slip adhesive t apes provide additional safety. They often have a grainy surface and are available for both indoor and outdoor areas.

Colour-coded warning tapes for industrial applications

Colours speak a clear language – even in industry. Yellow-black signals danger, red-white indicates prohibitions or restricted areas. The colour coding follows international standards and facilitates quick orientation in complex working environments.

When to use marking tapes or marking colours?

Marking paints are suitablefor outdoor areas due to the effects of the weather. Make sure the surface is dry and clean before applying. Paints with a high pigment content and therefore particularly high opacity are best suited for areas subject to particularly heavy use, such as markings on heavily frequented company premises with a fleet of lorries. The colours are simply sprayed on – either using a stencil or a marking trolley. Straight lines are also possible thanks to the chalk line. Marking tapes suitable for outdoor use also have their advantages: In contrast to spray paint, there is no drying time (around 10 minutes).

Self-adhesive marking t apes have established themselvesindoors . The advantages: No drying time, robust and removable if necessary. Depending on their properties, these marking t apes are also suitable for outdoor use. The following also applies when applying the marking tapes: The surface must be clean, dry and free of grease. And: For good adhesion to the ground, it is better not to overlap the tapes! A certain disadvantage is that only the shapes and symbols available on the market can be used for stick-on markings. Free shapes and symbols can only be sprayed on, for example with the help of stencils.

Temporary safety markings

If it is foreseeable that a marking will only be valid for a very limited time, safety markings that can be removed relatively easily should be used.

- Warning displays: These are generally very well recognised and are extremely flexible: they can simply be folded up and set up elsewhere. Of course, this mobility can also be a disadvantage: It is not 100% guaranteed that they will not be moved or removed improperly

- Traffic cones are easily recognisable thanks to their orange signal colour and are suitable for securing short-term danger zones or emergency sites. They can be used to mark a deep pothole on the company railings or to mark an area for maintenance work at short notice. The cones can also be connected using hooks and chains.

- Barrier posts or scissor grids are somewhat more stable for use. By filling the base with sand or water, the barrier is additionally weighted down. This prevents unintentional displacement. With a height of almost one metre, the posts are suitable for securing danger spots, but also for separating and securing access routes. Scissor grids can even be extended and locked up to a length of 2.25 metres.

- A belt cassette adheres to any metallic, magnetic surface and can therefore be used flexibly. Ideal for short-term separation of wet floor surfaces after cleaning or for maintenance work.

Safety labelling in various industries

Safety labelling is used across all industries:

Industry and manufacturing

In production halls, warning tapes are essential for labelling machine areas, safety distances and danger zones. They protect employees and visitors alike.

Construction sites and road traffic

Barrier tapes secure excavation pits, open shafts or danger zones. Marking tapes on vehicles and machines also help to make risks visible – especially at night or in poor visibility.

Retail and public buildings

In shopping centres, schools or public authorities, marking tapes ensure clear visitor guidance, accessibility and easily recognisable emergency exits. They can also be used quickly and flexibly for temporary guidance systems – for example during remodelling work.

Logistics and warehousing

In logistics centres, clearly visible routes are vital for forklift trucks and warehouse staff. Safety markings on the floor prevent collisions and support structured, efficient working.

Healthcare and laboratories

Extreme caution is required here: Warning tapes mark quarantine zones, hazardous material storage areas or sensitive areas in clinics. They contribute to hygiene, safety and compliance with legal requirements.

Tips on the correct use and durability of safety labelling

Clean preparation of the surface is crucial for warning tapes to be effective. Grease, dust or moisture can impair adhesion. Regular inspection and care extend the service life of the markings. If the tapes are damaged or worn, they should be replaced promptly – for maximum safety.

Conclusion: Safety labelling as the key to prevention

Warning and marking tapes are an indispensable aid when it comes to safety and orientation. They help to prevent accidents, optimise processes and comply with legal requirements – in almost all industries.

With the right selection and application, they make a decisive contribution to prevention. What’s more, new materials and technologies – such as luminous or particularly environmentally friendly versions – are making the future of safety labelling even more effective.