Adhesive tape is an integral part of our everyday lives and industry. But why does it actually stick? The answer lies in the physics and chemistry of adhesion and holding power. From simple applications such as gift wrapping to high-performance adhesive tapes in aviation – the possible uses are many and varied. In addition to design and technical aspects, scientific processes also play a role in adhesive tapes. In this article, we take a look at the scientific principles behind how adhesive tapes work.

Direct bonding? In our RAJA shop you will find a comprehensive range of adhesive tapes

1 – Basics of adhesive and adhesive strength

Adhesive force and bonding force are not the same thing; in fact, adhesive force is a component of bonding force. The adhesive force, also known as peel adhesion, is the force required to detach an adhesive strip from a bonded substrate. In accordance with DIN standard EN 1939:2003, the adhesive force is measured under laboratory conditions on polished steel. The adhesive strips are pulled off in a certain width (10, 25 or 50 mm) under specified conditions (defined pressure force, tearing speed and angle). Depending on how much force has to be applied to remove the adhesive strip from the substrate, the adhesive force is then divided into 3 gradations, with the value given in Newtons per mm. The following average values apply for a 25 mm wide adhesive tape:

- Low (weak) adhesive force: < 3.75 N/ 25 mm

- Medium adhesive force: approx. 3.75 to 7.5 N/25 mm

- High (strong) adhesive force: > 7.5 N/ 25 mm

Important information on adhesive strength

- Adhesive strength is generally better on smooth surfaces than on porous, rough and uneven surfaces.

- The adhesive strength depends on the properties of the backing material (stiff, flexible), the contact pressure, the adhesive and the ambient temperature: rubber adhesive, for example, liquefies under the influence of heat, which significantly reduces the adhesive strength.

- When buying adhesive tapes, never focus solely on the adhesive strength, because high adhesive strength does not mean that the adhesive tape can adhere everywhere, as the bonding conditions and the surface to be bonded are just as important for a good bonding result.

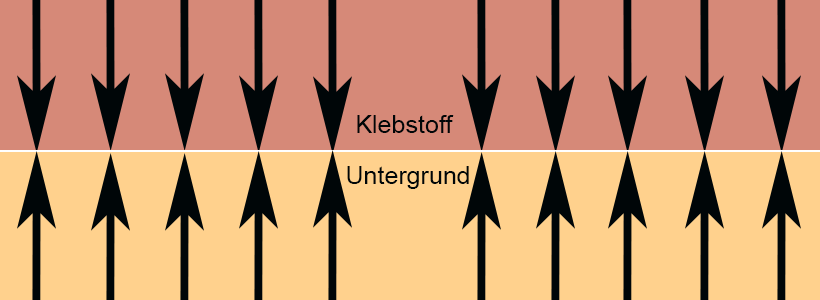

The 3 forces that act together within a pressure-sensitive adhesive are decisive for the adhesive strength:

Adhesion

Adhesion is the force of attraction or the adhesive force between the molecules of the adhesive and the bonded surface. The adhesive flows into small irregularities in the surface and forms a tight bond. High adhesion or adhesive strength means particularly good adhesion to the substrate. However, good adhesion says nothing about the long-term adhesion of an adhesive tape.

Immediate adhesion, also known as tack, is a form of adhesion, namely the initial tack. In other words, what happens when the adhesive first comes into contact with the surface to be bonded. This is because an adhesive needs time to cure completely, the so-called “open working time”. Tack indicates how quickly the adhesive bond must be formed. In the laboratory, the initial tack is tested at low contact pressure and is then divided into low, medium and high. This means that if a firm bond is already formed with low force and brief contact, this is referred to as high immediate adhesion or a high tack – the tougher the adhesive, the higher the immediate adhesion/tack.

✔ Good to know:

-

- Sometimes it is an advantage if the tack is not so high, for example if you want to correct the position of the tape again or if the tape is only to adhere to the surface for a short time and then be removed again without leaving any residue. Painter’s tape is a classic example of an adhesive tape with a low tack

- Caution: An adhesive tape with weak immediate adhesion can still have excellent final adhesive strength.

Cohesion

Cohesion refers to the internal bonding forces of the adhesive itself, i.e. how firmly the adhesive holds together. This prevents the adhesive tape from tearing or deforming. High cohesion means that the adhesive mass is very strong and inherently stable – i.e. tear-resistant. Acrylic adhesives, for example, have a high cohesion. High cohesion is important for adhesive tapes, for example, which need to hold greater weights. Cohesion is indicated by the shear strength. The shear strength describes the property of the adhesive tape not to shear or slip off. It is tested by loading a defined adhesive surface (e.g. 625 mm²) with a weight (e.g. 1 kg) placed vertically underneath and waiting to see whether and after how long the tape shears or slips. The shear strength is strongly dependent on the temperature: Some adhesives are more heat-resistant than others and thus only start to “flow away” or shear off later.

✔ Good to know:

- High cohesion is necessary, for example, if the adhesive strip is to be removed without leaving any residue; high cohesion ensures that the molecules in the adhesive are firmly bonded together and thus do not “tear apart” during removal. Adhesives with low cohesion often leave adhesive residue on the surface after removal. Adhesive tapes with high cohesion are therefore suitable for bonding that is only temporary, e.g. on sensitive surfaces .

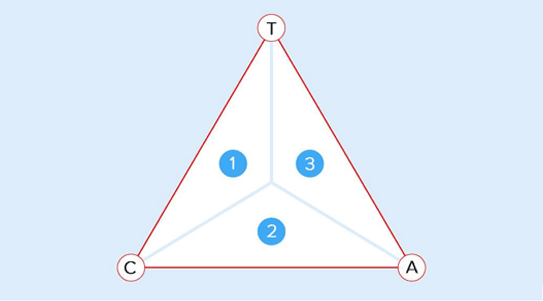

The ratio of the 3 forces cohesion (C), adhesion (A) and tack/immediate adhesion (T) determines the properties of the adhesive mass:

1) Temporary and reversible bonds: are dependent on cohesion and tack, adhesion is of secondary importance, as the bond is to be released again

2) Permanent bonds: Cohesion and adhesion are in the foreground. The strength of the bond is crucial. How strong the bond is at first is of secondary importance.

3) Quick-stick bonds: the adhesive bond must be made quickly

Other details that play a role in the selection of adhesive tapes:

- A high tensile strength or tear resistance is particularly important for single-sided packaging tapes, especially for packaging and transport securing tapes that have to hold heavy loads in place during transport. The tensile strength is the force/load required to tear the tape. It is measured in Newtons per cm (N/cm) by pulling a 1 inch wide strip of tape in the opposite direction at both ends until it tears. The same method is used to measure elongation at break. It is the percentage by which the tape can be extended before it tears. The elasticity of the backing material is decisive here. Elastic adhesive tapes such as fabric tapes usually have a high elongation at break as they are often used on irregular, rounded surfaces.

- The tape thickness is often specified in µ and refers to the total thickness of the tape without the release film. The thicker the adhesive tape, the more puncture-resistant it is – thick adhesive tapes are, for example, repair tapes, which are valued for their high rigidity. The disadvantage is that they are not very conformable and not very flexible.

- Temperature range/span describes the ability of the adhesive tape to withstand certain temperatures after bonding without reducing the adhesive performance. The temperature range is specified in °C from the lowest degree of cold to the highest. The tack of an adhesive often increases with rising temperatures, whereas the adhesive strength of the adhesive tape decreases. As temperatures fall, the tack decreases accordingly.

- The ageing resistance indicates how long an adhesive tape will last, i.e. how long it can be used without losing its adhesive strength.

- Other factors such as the surface finish and material properties influence adhesion. The rougher a surface, the more difficult it is for the adhesive to bond to it. There are also differences between temporary and permanent adhesion, which vary depending on the type of adhesive tape.

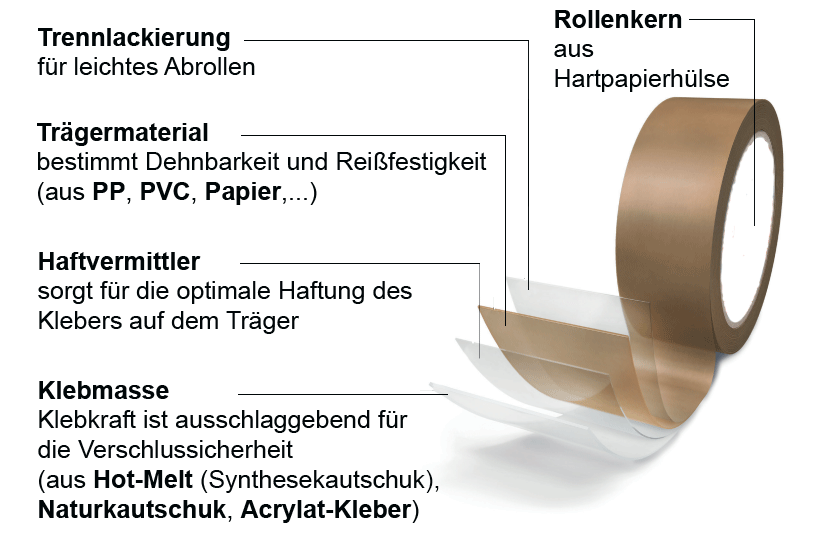

2 – The chemical composition of adhesive tapes

Carrier materials

The backing material gives the adhesive tape its stability and flexibility. The backing material has the task of carrying the adhesive and the bonding agent. It therefore also determines the tear resistance and stretchability of an adhesive tape. Where, how long, on which surface and for which purpose the tape is used determines which backing material is suitable. The following backing materials are the most common:

- Plastics such as PVC, polyethylene or polyester

- Paper for environmentally friendly alternatives

- Fabric for particularly tear-resistant adhesive tapes

- Metal foils for heat-resistant special applications

The most common types of adhesive tape for packaging are film tapes made of PP (polypropylene carrier material) or PVC (polyvinyl chloride carrier material) and paper tapes (paper carrier material). There are also other backing materials such as cotton, fleece and viscose for fabric tapes and metal (e.g. aluminium adhesive tape) for adhesive tapes that are primarily used in industry, trade and construction.

| PP (polypropylene) | PVC (polyvinyl chloride) | paper |

Advantages

|

advantages

|

Advantages

|

Disadvantages

|

disadvantages

|

disadvantages

|

Area of application

|

Range of application

|

Application range

|

✔ Expert test: Is it a PP or PVC adhesive tape?

The biros test can be used to easily determine whether it is a PP or PVC tape. To do this, stick the end of the tape to the edge of a table, unroll it and stretch it slightly. Now prick the stretched tape with a biro. If the tape tears, if it is PP, there will be a hole around PVC.

Other carrier materials for packaging tapes

- Wet adhesive tape is a packaging tape made of paper with an odourless adhesive (vegetable glue) that is activated with water. This creates such a strong bond that the tape cannot be removed from the carton without being seen. This type of tape is recyclable, insensitive and also adheres to dusty surfaces. It can only be used in conjunction with a manual or electronic tape dispenser with a water tank, which moistens and cuts the adhesive tape strips.

- Filament tape or filament-reinforced packaging tape is a PP packaging tape with hot-melt adhesive that is reinforced with longitudinal glass fibre threads and is therefore very tear-resistant. It has high immediate and permanent adhesion. It is used for shipping hazardous goods and is also suitable for heavy export shipments. Filament tape does not tear if punctured or otherwise damaged. The incorporated bundles of numerous wafer-thin, parallel glass fibres or polyester threads (also known as “roving”) have a much higher tear resistance and stop the tape from tearing further. Even a cut or tear at the edge of the tape cannot harm the filament adhesive tape. The main difference between the various filament tapes is the orientation of the thread reinforcement. This acts in the direction of the filament bundles. A longitudinally reinforced adhesive tape is therefore particularly tear-resistant in the longitudinal direction. In addition, it does not tear completely in the event of cuts or tears in the transverse direction, but remains stable. There are also packaging tapes that are reinforced lengthways and crossways and are therefore particularly tear-resistant in both directions. The crossed, net-like reinforcement also makes the tape very resistant to tears in the transverse and longitudinal directions and to perforation.

Other backing materials for adhesive tapes for use in industry and trade

- Crepe adhesive tapes are used for masking during painting or cleaning and for special applications in production. However, it is best known for its use in the craft sector, primarily by painters. Crepe tape is ideal for masking walls or for defining straight lines and sections when painting. Crepe adhesive tapes have hotmelt (low quality) or natural rubber adhesive (high quality) and are made from crepe paper (also known as flat crepe). Painted parts are often heated to high temperatures in ovens. Therefore, crepe adhesive tapes must be heat-resistant. Crepe tapes can be removed without leaving any residue.

- Adhesive tapes with a metallic carrier materialare usually used wherever electronics are involved. Due to their ageing and temperature resistance and their ability to conduct electricity, they can serve as a heat barrier in electrical devices. One example: aluminium adhesive tape.

- What is the grey adhesive tape called? Adhesive tapes are not only used for packaging, but also in industry and trade different types of adhesive tapes are used for different purposes: Fabric tape is tape reinforced with textile fabric or tear-resistant plastics (PET). It is very hard-wearing, has a high tensile strength but can often be torn by hand. It is therefore very suitable for bundling, sealing or insulating. The best-known example is the usually silver-grey gaffa tape.

Types of adhesive and their properties

Not all adhesives are the same – different chemical compositions are used depending on the requirements. There are 3 adhesives that are most commonly used for the adhesive mass of an adhesive:| Hot-melt | Acrylic adhesive | Natural rubber |

|

Hot-melt adhesive is used for PP packaging tapes. As the name suggests, it is a synthetic hot-melt adhesive. This means that the synthetic adhesive granulate is melted by heating and applied to the carrier material at a temperature of approx. 90 °C. It is suitable for light to medium-duty applications. It is suitable for light to medium-weight cardboard packaging and for short-term storage and despatch. |

Acrylic adhesive is a synthetic adhesive in which the raw materials are dissolved in a water dispersion. This dispersion is applied to the carrier film and the liquid is vaporised in an oven. Acrylate adhesives are significantly more efficient than natural rubber or synthetic rubber adhesives It is suitable for light to medium-weight cardboard packaging and for longer transport routes without climatic fluctuations. |

Natural rubber adhesive consists of 97% natural rubber and approx. 3% solvent. Natural rubber is the most environmentally friendly adhesive option and is considered the highest quality adhesive material on the market. |

|

Advantages

|

Advantages

|

Advantages

|

|

Disadvantages:

|

Disadvantages:

|

Disadvantages:

|

✔ Good to know:

- PP tape can be provided with three different adhesives: Hotmelt, acrylate or natural rubber. PVC adhesive tape and paper adhesive tape are available in different qualities and thicknesses, but always with natural rubber as the adhesive. Wet adhesive tape is provided with vegetable glue.

Types of adhesive tapes and their applications

There are different types of adhesive tape depending on the intended use:

- Packaging tapes: Ideal for the secure sealing of cardboard boxes. These are available in various materials such as PP, PVC or paper.

- Fabric adhesive tapes: Very resistant and ideal for repairs or industrial applications.

- Double-sided adhesive tapes: Perfect for invisible fastenings, e.g. in advertising technology or trade fair construction.

- Special adhesive tapes: These include heat-resistant tapes, painter’s crepe or anti-slip tapes for safety applications.

In our blog Adhesive tape types-What adhesive tape do I use for what? we take a closer look at the different types of adhesive tape and their respective purposes.

3 – How adhesive tape adheres to different surfaces

The adhesive strength can vary depending on the surface:

- Smooth surfaces such as glass or metal allow for better adhesion.

- Rough surfaces offer less contact surface for the adhesive.

- Moisture, temperature and dirt have a significant influence on the adhesive strength.

- Materials such as silicone or Teflon are difficult to bond as they have low surface energy.

In our blog on the topic of “Adhesive tape on different surfaces:What to look out for?” we go into detail about the surfaces and the respective adhesive tapes.

4 – Physical and chemical effects behind adhesion

The adhesive strength of adhesive tapes is based on a combination of physical and chemical effects that work together to create a reliable bond between the tape and the surface. A good adhesive tape must offer an optimum balance between adhesion and cohesion and be adapted to different surface and environmental conditions. In addition to adhesion and cohesion (see above), the following effects are decisive:

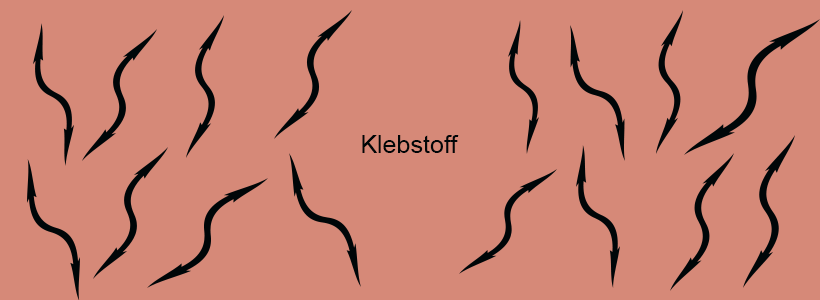

Viscosity and flow properties

- Viscosity describes the viscosity of the adhesive and influences how well it can adapt to the surface.

- Mechanism:

- A low-viscosity adhesive can penetrate the microstructures of the surface better and thus generate a higher level of adhesion.

- High-viscosity adhesives are often more resistant to mechanical stress.

Mechanical anchoring

- The adhesive can penetrate pores and irregularities in the surface and be anchored there.

- Mechanism:

- Particularly important for rough surfaces such as cardboard or wood.

- The mechanical interlocking supports the adhesion in addition to the chemical bonds.

Molecular interactions

- van der Waals forces:

- These weak attractive forces occur during adhesion between the molecules of the adhesive and the surface.

- Hydrogen bonds:

- If the surface and the adhesive contain polar groups, hydrogen bonds can form, which strengthen the adhesion.

- Ion and dipole-dipole interactions:

- Especially with special adhesive tapes with polar or ionic components such as double-sided adhesive tapes for metal, plastic or glass with acrylate adhesive or industrial adhesive tapes made of PU.

Polymerisation and chemical reactions

- Some adhesives cure through chemical reactions, e.g:

- UV-curing adhesives: Cure by irradiation with UV light.

- Two-component adhesives: Only react after mixing the components.

- Moisture-curing adhes ives: React with moisture in the air (e.g. silicone adhesives).

A good adhesive tape must offer an optimum balance between adhesion and cohesion and be adapted to different surface and environmental conditions.

5 – Why is adhesive tape sometimes difficult to remove?

Removing adhesive tape can be challenging. Reasons for this are:

- Residue: Some adhesives harden over time and leave marks.

- Dwell time: The longer the adhesive tape sticks, the stronger the bond.

There are various adhesive removal methods: Heat, oil or special adhesive removers can help prevent residue.

6 – Innovations and future developments in adhesive tape technology

Research into new adhesive technologies is in full swing. Future developments include:

- Environmentally friendly adhesives: Sustainability also plays a role in the development of adhesive tapes. For example, research is being conducted into biodegradable and solvent-free alternatives.

- Nano adhesives: Adhesives based on carbon nanotubes have an enormous adhesive force of 100 newtons per cm² – 10 times that of gecko feet. In addition to the extremely good adhesion, the adhesive is also easy to remove from the surface, which makes it interesting for many technical applications such as wind turbines.

- Reusable adhesives: The University of Kassel has decoded animal superglue and is trying to develop sustainable organic superglue from it.

Conclusion

Adhesive tape is far more than just a simple tool and anything but boring – it is based on complex physical and chemical principles. Thanks to constant innovation, it is becoming ever more versatile and sustainable. Whether in industry, household or high-tech applications: The science behind adhesive and bonding power remains fascinating!