Whether in online retail, industrial logistics or for specialised B2B shippers – filling materials are a crucial component of any shipping packaging. They protect sensitive products, prevent transport damage, improve the unboxing experience and, in the best case scenario, even communicate brand values such as sustainability. However, not every filling material is suitable for every product.

This comprehensive guide will help you navigate the world of filling materials. We compare the most common options, highlight their properties, advantages and disadvantages as well as their areas of application and the role of sustainability, and help you find the right solution for your shipping process.

Market development & importance of filling material

Filling and cushioning materials are part of the protective packaging sector. An area that is constantly growing: according to Fortune Business Insights, the global market for protective packaging was estimated at USD 38.52 billion in 2023. The market is expected to grow to USD 61.44 billion by 2030, which corresponds to a compound annual growth rate (CAGR) of 6.90%. The European market for protective packaging is expected to register a CAGR of 3.4% during the forecast period 2020-2027. (Mordor Intelligence)

These growth rates show how the market is being driven by increasing demands for product safety, sustainability and automation.

Why is the right filling material crucial for shipping?

A parcel is subjected to numerous shocks, vibrations and jolts on its way to the recipient. Without the right protection, even robust products can be damaged. The right filling material performs three key functions in the parcel that are essential for safe transport:

- Cavity filling: It fills empty spaces in the box. A well-filled parcel prevents the goods from shifting in the box during transport or bouncing against the side walls. This fixation is essential to prevent damage caused by movement during transport.

- Cushioning and shock absorption: Filling materials absorb the energy of shocks and vibrations. Sensitive products, especially fragile goods, require effective cushioning to protect them from breakage or other damage. The filling material acts as a buffer zone here.

- Fixing several items: If a parcel contains several items, the filling material prevents them from bumping into and damaging each other during transport.

The right filling material is an investment in customer satisfaction and the efficiency of the shipping process. It minimises complaints, returns and the associated administrative effort as well as the costs for replacement deliveries. Ultimately, it makes a significant contribution to ensuring that the goods reach the recipient safely and undamaged.

A comparison of the most important filling materials: properties, advantages and disadvantages

There are many ways to protect goods during shipping and transport and to fill cavities. You can read about the exact differences between filling and cushioning in the blog Filling and cushioning: how to protect your products economically and safely during shipping.

Important to know: Not all filling materials are the same: air cushions, paper padding, packaging chips, packing paper, wood wool or tissue paper – each material has its advantages and disadvantages.

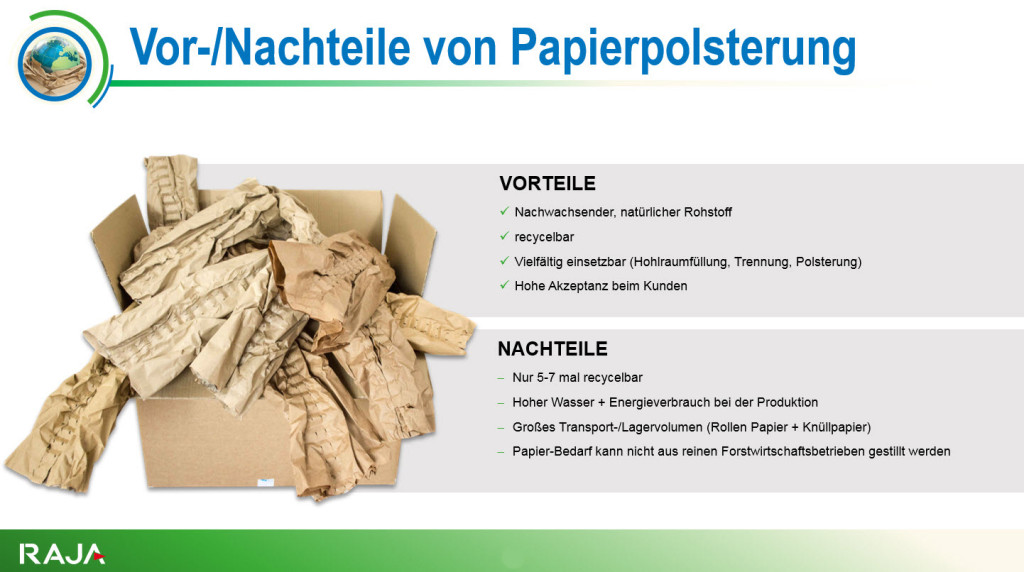

1. paper-based filling materials: sustainability meets flexibility

Paper is a classic in the field of filling and padding materials – and not without reason. Paper padding variants such as crumpled paper, packing paper and corrugated cardboard rolls offer a wide range of applications.

Properties: Paper padding is robust, flexible, often made from recycled material and, when used correctly, has good dimensional stability.

Advantages:

- Environmentally friendly: Paper padding materials are often made from recycled waste paper and are themselves recyclable. This makes them ideal for companies that want to operate sustainably.

- Versatility: Paper is suitable for void filling as well as for cushioning and fixing and adapts well to the shape of the packaged goods. With sufficient volume and the correct crumpling technique, paper offers surprisingly good shock absorption. Machine-formed paper cushions are particularly effective here.

- Easy handling: Paper can be quickly formed, crumpled or folded by hand or with the help of paper cushioning machines. The filling material can be disposed of together with the cardboard, which is a great advantage for the end user.

Disadvantages:

-

- Higher space requirement: When uncompacted, paper can take up a lot of storage space.

- Weight: Paper can be heavier than bubble wrap or packing chips, which can affect shipping costs.

- Manual labour: Crumpling packing paper can be time consuming, although paper dispensers or machines increase efficiency.

- Paper reaches its limits when subjected to heavy force or impact – especially when compared to air cushioning materials. In addition, large cavity volumes also require a lot of paper, which increases packaging costs and environmental impact.

Ideal for:

- medium to heavy items that require good fixation.

- sensitive goods that require flexible padding.

- Companies that value an environmentally friendly packaging material.

- Suitable as a protective layer between products or for covering surfaces.

Typical applications:

- Shipping of textiles, books or decorative items

- E-commerce shops with sustainable positioning

- Shipping of non-sensitive consumer goods

2. air cushions and air pillows: Maximum product protection with low weight

Air cushions and bubble wrap are among the most effective protective materials in shipping.

Air cushions and bubble wrap are among the most effective protective materials in shipping.

Properties: They are typically made of polyethylene (PE) and are filled with air by machine on site or used directly as rolls.

Advantages:

- Outstanding cushioning: Air-filled materials offer excellent shock absorption. The air acts as a buffer that reliably absorbs the impact energy – making them ideal for sensitive or fragile products. Bubble wrap effectively protects fragile items from breakage and scratches. Air cushions are ideal for fixing and cushioning.

- Extremely light: Low weight helps to reduce shipping costs.

- Low material consumption: Compared to other materials, less material is often required for the same volume of cushioning.

- Water-repellent: Offers a certain degree of protection against moisture.

- Space-saving (air cushion): As a machine-fillable variant, they require little storage space as they are only filled when needed. They can be used time-efficiently in automated dispatch lines.

Disadvantages:

- Environmental aspect: Traditionally made of plastic (PE film), which can still pose an environmental problem if it is not disposed of correctly, despite being recyclable. – However, there are now also recyclable and climate-neutral films that are 100% recycled or paper air cushions.

- Less suitable for filling cavities: While air cushions are good for filling cavities, bubble wrap is more suitable for directly wrapping and cushioning goods.

- Static charge: Plastic-based bubble wrap can be statically charged, which can be a problem with sensitive electronics.

- Bubble wrap systems always mean an investment in machinery, which is not always economically viable. The filling material and the cardboard must be disposed of separately.

Ideal for:

- Fragile goods, glassware, ceramics, delicate surfaces that require both cushioning and protection from scratches.

- Air cushions are ideal for securing light to medium-weight products.

Typical applications:

- Glass products, porcelain or household appliances

- Products with a higher value of goods or transport risk

3. flexible filling material for many areas of application

Packaging chips are loose filling materials that can be used flexibly and are therefore often used to fill cavities in cardboard boxes. They are available in two main variants: made from polystyrene (EPS) or from biodegradable materials such as corn starch. An increasingly popular alternative is paper padding chips – a sustainable solution made from recycled paper. However, the chips must completely enclose the goods to ensure a cushioning function from all sides.

Packaging chips (EPS & biochips)

Advantages:

Advantages:

- Excellent void filling: packaging chips trickle into even the smallest gaps and are particularly suitable for products with irregular shapes, as they adapt to the respective conditions.

- Very light: this reduces the overall weight of the parcel and therefore the shipping costs.

- Good shock absorption: provides some cushioning by absorbing and distributing shocks.

- Corn starch variants are 100% biodegradable, compostable and even water-soluble

Disadvantages:

- Although the flo-pak® standard packaging chips are made from 100 % recycled polystyrene or, as flo-Pak NATURAL, even from plant starch, they still have a bad reputation, particularly from an environmental point of view. The chips are statically charged and quickly spread around the room when opened. The visual impression is also of poor quality, which can be perceived negatively by discerning customers. In addition, the material must always be disposed of separately from the cardboard box

- Slipping of the goods: If the filling is insufficient or the products are heavy, the goods can slip or “settle” in the parcel.

- Unwanted spreading: When the parcel is opened, chips can easily fall out and spread around the room.

Ideal for:

- Light to medium-weight products that are individually packed and mainly require cavity filling.

Typical application examples:

- Spare parts, cables, small parts

- Series shipping with a varying product portfolio

- Shipping to workshops or B2B wholesalers

Paper padding chips

Advantages:

- Paper cushioning chips combine the flexibility of classic packaging chips with the advantages of sustainable materials. They are made from recycled paper, are 100% recyclable and also have an attractive appearance. Their textured surface ensures good dimensional stability so that products sit securely in the carton.

Disadvantages:

- Compared to air cushions or customised inserts, paper chips only offer limited impact protection. They are also more expensive than conventional chips – but they score highly in terms of environmental friendliness and brand impact.

Typical application examples:

- Natural cosmetics, manufactured products, sustainable e-commerce

- Gift ranges with a focus on ecology and aesthetics

- Companies that consciously do without plastic

4. foam sheets and upholstery mats

Foam sheets made of PU or PE are often used to protect highly sensitive products. However, there are also environmentally friendly padding mats made from recycled textiles (cotton, wool, linen and hemp).

Foam sheets made of PU or PE are often used to protect highly sensitive products. However, there are also environmentally friendly padding mats made from recycled textiles (cotton, wool, linen and hemp).

Properties: PE foam sheets are made of dense, resistant material: closed-cell, water-repellent with high damping properties. They are mainly used for fixing in the package.

Advantages:

- Excellent shock absorption: Foams offer maximum shock absorption, dimensional stability and anti-static properties, even with low material thickness.

- Custom-fit padding: Ideal for sensitive, expensive or fragile items as it can be customised to the exact shape of the product (e.g. in suitcases or shipping boxes).

- Dust-free and abrasion-resistant: Leaves no residue on the goods.

- Reusable: Can be used several times if handled carefully.

- Textile cushioning mats are particularly flexible and adapt to any product shape. They do not cause static electricity or corrosion and are particularly light and reusable.

Disadvantages:

- Low environmental friendliness: PE foam is recyclable, but the recycling process is often more complex and less common than with paper.

- Cost-intensive: Customised products or precise cuts can be expensive.

- Not for cavity filling: Less suitable for filling cavities in large packages, but rather for direct product padding.

- High space requirement: Foam sheets require a comparatively large amount of storage space.

Ideal for:

- High-quality electronics

- Collector’s items or other very delicate and expensive products that require maximum protection.

Typical examples of use:

- Transport of machine components and sensitive electronics

- Medical technology, measuring instruments or optical devices

- High-risk export shipments

5. decorative natural materials: wood wool, paper wool & co.

Packaging with natural materials is still on the rise – not only for environmental reasons, but also for aesthetic reasons.

Advantages:

Advantages:

- Very environmentally friendly: wood wool is 100% biodegradable and made from a renewable raw material. Paper wool or packing silk are also comparatively sustainable

- Decorative appearance: ideal for high-quality padding of gift items or insensitive premium products. They not only convey an ecological image, but also significantly enhance the unboxing experience.

- Antistatic and breathable: Well suited for sensitive goods that must not be statically charged or need to “breathe”.

Disadvantages:

- Can dust/splinter: Fine wood particles can come loose, which is not ideal for all products or recipients.

- They offer little impact protection and are therefore only suitable for light or insensitive products.

- Moisture-sensitive: Wood absorbs moisture, which can be problematic in humid environments.

- Weight: Significantly heavier than plastic or bubble wrap, which can increase shipping costs.

- Not suitable for all goods: Not ideal for food products without additional protective packaging or products that need to remain absolutely dust-free.

Ideal for:

- Products that require a natural and high-quality presentation. Also for cavity filling in gift boxes.

Typical examples of use:

Typical examples of use:

- Gift sets, delicatessen, wine bottles, spirits, natural cosmetics

- Natural cosmetics or handmade products, arts and crafts, ceramics

- Companies with a zero-waste or eco-orientation

Other materials for specific applications:

- Corrugated cardboard pads/rolls: Excellent for edge protection, stabilisation or as intermediate layers. Very sustainable and recyclable. Ideal for securing heavy products.

- Shredded cardboard material: An excellent do-it-yourself solution for making filling material from old cardboard boxes. Very environmentally friendly as it reduces waste and provides good void fill.

| Filling material | Product protection | Sustainability | Unboxing experience | Typical application |

|---|---|---|---|---|

| Paper padding | Medium | High | Good | Textiles, books, decorative items |

| Air cushions/foil | High | Medium | Neutral | Electronics, glass, small appliances |

| Packaging chips (EPS) | Medium | Low | Weak | Spare parts, wholesale, grouped goods |

| Packaging chips (organic) | Medium | High | Low | Sustainable B2B shipping, workshop supplies |

| Paper cushioning chips | Medium | High | Good | Sustainable online trade, manufactured products |

| Foam sheets | Very high | Low | Neutral | Industry, medical technology, export packaging |

| Wood wool / natural fibres | Low | High | Very good | Gift packaging, natural cosmetics, delicatessen |

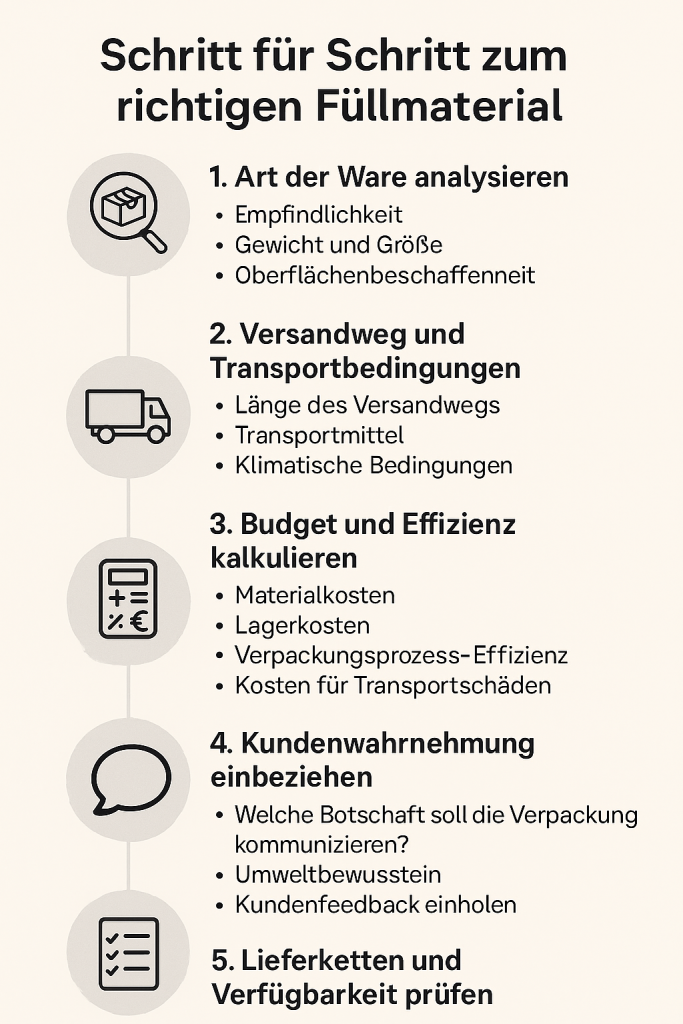

The selection process: finding the right filling material for your needs

Deciding on the right filling material is a process that goes far beyond the mere cost factor. Consider the following steps to make the best choice for your shipment:

1. analyse the type of goods

- Sensitivity: How sensitive is the product? Is it sensitive to scratches? Are they electronic products that require antistatic protection, for example? Is the product fragile (glass, ceramics, electronics) or robust (textiles, books)? Fragile goods require maximum padding (bubble wrap, PE foam, thick paper padding).

- Weight and size: How big and how heavy is the product? Heavy items require firm filling material that can support the weight (paper padding, corrugated cardboard). Lightweight items can benefit from lighter materials such as packaging chips or air cushions.

- Surface texture: Is the surface sensitive to scratches? Then soft materials such as bubble wrap or thin packing paper are ideal for wrapping.

- Shape: Irregular shapes benefit from loose filling materials that conform well (packaging chips, wood wool, shredded paper).

2. consider the shipping route and transport conditions

- Length of the shipping route: Short, local deliveries have a lower risk than international shipments with several transhipment points. Longer routes often require more protection.

- Means of transport: Will the parcel be transported by lorry, rail, ship or plane? Each means of transport has different vibration and shock profiles.

- Climate: Will the parcel be exposed to moisture or extreme temperatures? This could influence the choice of materials such as wood wool.

3. calculate budget and efficiency

- Material costs: What is the shipping volume? Compare the purchase prices per volume unit or per parcel.

- Storage costs: How much storage space does the filling material take up? Unfilled air cushion film is very efficient here.

- Packaging process efficiency: How quickly and easily can the material be used? How automated is the process? Automated paper padding or air cushion machines can reduce labour costs for high volumes.

- Cost of damage in transit: Consider the cost of the filling material in relation to the potential cost of returns, replacements and reputational damage. A slightly more expensive but more effective filling material can pay off in the long term.

4. incorporate environmental awareness and customer perception

- What message should the packaging communicate?

- Sustainability strategy: Do you want to be perceived as an environmentally conscious company? Then recycled paper products, organic packaging chips or wood wool are a good choice.

- Customer feedback: Ask your customers what type of packaging they prefer.

5. check supply chains and availability

- Make sure that your preferred filling material can be sourced reliably and in sufficient quantities from your supplier, especially if you operate an online shop or an e-commerce company with high shipping volumes.

Conclusion: The right filling material depends on the product and the objective

Choosing the right filling material is an art in itself that requires careful consideration of various factors. It’s not just about filling cavities, but also about protecting your goods in the best possible way, avoiding transport damage and at the same time taking ecological and economic aspects into account.

Those looking for sustainable shipping solutions are well advised to use paper padding or natural materials. For sensitive goods or complex logistics, the use of air cushioning or paper cushioning systems is recommended. For all-round applications with a low cost focus, packaging chips can still make sense.

A well thought-out packaging strategy that combines protection, efficiency and sustainability is the key to successful and safe shipping in today’s world. If you need support, we at Rajapack will be happy to help you with a comprehensive needs analysis.