Adhesive tapes are indispensable in industry, trade and the home. They offer fast, reliable fastening solutions for a wide range of materials – from wood and plastic to glass. However, not every adhesive tape adheres equally well to every surface.

The nature of the surface plays a decisive role in the adhesive strength. Smooth, porous or textured surfaces require customised adhesive solutions. The wrong adhesive tape can either fail to adhere or leave unsightly residues. Which adhesive tape for which surface? We get to the bottom of this question in this article and provide practical tips for optimum adhesion.

1 – The basics of adhesion

How adhesive tapes adhere: mechanical vs. chemical adhesion

In order to achieve the optimum result and the optimum bond between the adhesive tape and the substrate, it is first important to understand how adhesive tape “works”.

The adhesive strength of an adhesive tape is determined by two main mechanisms:

- Mechanical adhesion: the adhesive penetrates small imperfections in the surface and anchors itself there. This is particularly important for rough materials such as wood or fabric.

- Chemical adhesion: Interactions between the molecules of the adhesive and the surface play a role here. Crucial for smooth materials such as glass or metal.

What different types of adhesive tape are there? What is an adhesive tape made of and which materials and adhesives are suitable for which purpose? We answer these and other questions in detail in another blog article: Types of adhesive tape – What are adhesive tapes made of?

Influence of material properties and surface structure

Different surfaces influence the adhesive force:

✔ S mooth materials (glass, metal): High chemical adhesion, but sensitive to moisture and more extreme temperatures.

Rough surfaces (wood, concrete, fabrics): Mechanical adhesion plays a greater role, special adhesive tapes are required.

Low-energy plastics (e.g. polypropylene, PTFE): Very difficult to bond, special adhesion promoters are often required.

Factors such as temperature, moisture and dirt

Even the best adhesive tapes can fail if environmental influences are not taken into account:

- Temperature: environments that are too cold reduce the adhesive strength, high temperatures can soften the adhesive. In which temperature range does an adhesive tape feel “comfortable”? Read more here: The plastic melting point – does heat damage adhesive tape?

- Moisture: Reduces adhesion, especially on smooth surfaces such as glass or tiles.

- Dirt & grease: Prevents the adhesive from sticking properly – thorough cleaning is essential!

These external factors influence the “finished adhesive bond”, i.e. how durable the bond between the substrate and the adhesive tape is – but they already have an effect on the adhesive tape BEFORE it is applied. For this reason, it is important to find out about the correct storage of the adhesive tape types.

2 – Adhesive tape on different surfaces

The choice of the right adhesive tape depends heavily on the surface material. Not every surface offers the same basis for adhesion, which is why special adhesive tapes have been developed to adhere particularly well to certain materials. Glass and metal are often very smooth, which allows for high chemical adhesion – but also means that some tapes fall off easily. Rough and porous materials such as wood or fabric, on the other hand, require mechanical anchoring as the adhesive has to penetrate the structure. Plastics can be a challenge, as many of them have a low surface energy and are difficult to bond. Environmental influences such as temperature, moisture and dirt also have a significant impact on the adhesive strength.

To ensure that your adhesive tape holds optimally, it is important to choose the right product for each surface. Below, we look at the special features of different materials and give you specific tips on which adhesive tapes are best suited and how you can achieve permanent or residue-free adhesion.

Adhesive tape on glass

Glass is one of the smoothest surfaces, which allows for good chemical adhesion. However, adhesive tape can come off quickly due to moisture or temperature fluctuations, and residues are particularly noticeable.

Suitable adhesive tapes: Transparent or double-sided adhesive tapes, suction cup adhesive techniques

Tips for residue-free removal: Dissolve with isopropanol or cooking oil, peel off carefully

Improve long-term adhesion: Degrease the surface, pay attention to the temperature – solar radiation can play a particularly important role here!

Special case: Adhesive tape on window glass

Sunlight can have a considerable effect on the properties of adhesive tape on glass. Here are the most important effects:

Heating of the glass surface

Glass stores heat particularly well. Direct sunlight can cause temperatures of 50 °C or more, especially on windows or car windscreens. This heat can soften or even melt the adhesive of standard adhesive tapes, causing the tape to lose its adhesive strength and peel off.

UV radiation degrades the adhesive

UV radiation is one of the main causes of material fatigue in adhesive tapes. Many conventional adhesives, especially those based on acrylic or rubber, degrade under prolonged UV exposure. This can lead to

✔ The adhesive tape dries out and becomes brittle, causing it to crack or become brittle.

✔ The adhesive changes chemically and leaves a stubborn, difficult to remove layer on the glass.

✔ The tape turns yellow or discoloured, which is particularly unattractive with transparent adhesive tapes.

Condensation & moisture

Glass surfaces that heat up during the day and cool down again at night can form condensation. This moisture can creep under the adhesive tape and reduce the adhesive strength, especially if the tape has already been weakened by UV radiation.

Solutions: Which adhesive tapes can withstand the sun?

- UV and heat-resistant adhesive tapes (e.g. made from modified acrylate adhesive)

- Special outdoor adhesive tapes that have been developed for extreme weather conditions

- Heat-resistant silicone adhesive tapes that retain their elasticity even at high temperatures

- Protection by an additional cover to reduce direct UV radiation

Adhesive tape on metal

Metal surfaces vary greatly – from polished, mirror-smooth surfaces to rough or coated variants. The adhesive strength can vary greatly depending on the structure and ambient temperature. Heat-resistant and corrosion-free adhesive tapes are particularly in demand for industrial applications.

Smooth metal: Strong chemical adhesion, sensitive to grease and moisture

Rough metal: Mechanical adhesion plays a greater role, rough structure can absorb adhesive

Heat and cold-resistant variants: Special high-temperature adhesive tapes for extreme conditions

Adhesive tape on plastic

Plastics pose a particular challenge, as many types – especially polyethylene (PE) and polypropylene (PP) – have a very low surface energy. As a result, conventional adhesive tapes often adhere poorly or not at all. Special adhesive tapes with modified adhesives or the use of primers can improve adhesion.

Problem cases: Polypropylene & polyethylene – low surface energy makes adhesion difficult

Solution: Use special adhesive tapes with acrylate adhesive or adhesion promoter

For uneven plastics: Choose double-sided adhesive tape for uneven surfaces

Adhesive tape on wood

Wood can be both smooth and heavily textured, which makes choosing the right adhesive tape crucial. While untreated wood can absorb the adhesive, adhesive tapes often leave unsightly residues on varnished wood. The right adhesive ensures that the tape holds without damaging the material.

Painted wood: Easy to stick to, but residues can damage the paint

Untreated wood: Rough, absorbs adhesive – extra strong adhesive tapes required

Gentle removal: Peel off slowly or heat with a hairdryer

Adhesive tape on fabric & textiles

Textiles are soft, flexible materials that require mechanical adhesion. Conventional adhesive tapes often adhere poorly or leave residues that are difficult to remove. Special textile or double-sided adhesive tapes are a good solution for joining fabrics temporarily or permanently.

Alternative to sewing: textile adhesive tapes for temporary fastenings

Residue-free removal: Clean with heat or alcohol

Pay attention to flexibility: Stretchy fabrics require elastic adhesive solutions

Adhesive tape on walls & wallpaper

Walls and wallpaper are sensitive surfaces that can easily be damaged if the wrong adhesive tape is used. Residue-free removal is particularly important when painting or decorating. Masking and mounting tapes (or painter’s or masking tape) with weak adhesive or special coatings protect the surface. Special plastering tape is also ideal for use outdoors and on slightly rough surfaces such as brickwork and stone – and can be removed without leaving any residue within 4 weeks.

Painting and masking tapes: Specially developed for sensitive wallpapers

Avoid damage: Peel off slowly at a shallow angle

Long-term adhesion: Use double-sided mounting tape for heavy objects

Adhesive tape on ceramics & tiles

Ceramic tiles are available in smooth or textured versions, which influences the adhesive properties. While many adhesive tapes have difficulty sticking to glazed surfaces, joints and rough surfaces can provide additional grip. Waterproof adhesive tapes are particularly important in damp environments such as bathrooms.

Glazed tiles: Smooth, but sensitive to moisture – strong adhesive tapes required

Textured tiles: Mechanical adhesion required, use thicker adhesive layers

For damp rooms: Choose resistant, waterproof adhesive tapes

3 – Tips for optimum adhesion to any surface

As different as the properties of the various surfaces are, there are still a few general tips for achieving ideal adhesion of the adhesive tape.

Clean the surface thoroughly

Dust, dirt, grease or moisture are the most common causes of poor adhesion. The surface should be thoroughly cleaned and dried before applying the tape. It is best to use a lint-free cloth in combination with a suitable cleaning agent:

Dust, dirt, grease or moisture are the most common causes of poor adhesion. The surface should be thoroughly cleaned and dried before applying the tape. It is best to use a lint-free cloth in combination with a suitable cleaning agent:

- Glass, metal & plastic: Degrease with isopropanol or glass cleaner.

- Wood & porous materials: Sand lightly to increase the adhesive surface.

- Textiles & fabrics: Remove dust and fibre residues with a lint roller.

Important: Do not use cleaning agents containing oil, as they can leave behind a protective layer that impairs adhesion.

✔ Use a primer or adhesion promoter

Some materials, especially low-energy plastics such as polypropylene (PP) or polyethylene (PE), are difficult to bond. In such cases, special primers or adhesion promoters can help by chemically roughening the surface and thus improving the adhesive strength.

Some materials, especially low-energy plastics such as polypropylene (PP) or polyethylene (PE), are difficult to bond. In such cases, special primers or adhesion promoters can help by chemically roughening the surface and thus improving the adhesive strength.

✔ Plastic surfaces: acrylate-based primers ensure better adhesion.

Smooth metal or glass: Special adhesion promoters can help if the adhesive tape comes off too easily.

✔ Wood & porous surfaces: Treat with a thin layer of varnish or sealant beforehand to prevent the adhesive from seeping into the material.

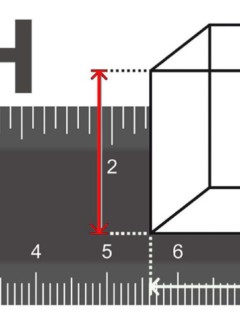

✔ O bserve the temperature – optimum processing temperature is usually between 15-25°C

The ambient temperature has a major influence on the adhesive strength. Most adhesive tapes adhere best at temperatures between 15 °C and 25 °C. If it is too cold, the adhesive becomes brittle and adheres less well; if it is too hot, the adhesive can become soft and lose its adhesive strength.

The ambient temperature has a major influence on the adhesive strength. Most adhesive tapes adhere best at temperatures between 15 °C and 25 °C. If it is too cold, the adhesive becomes brittle and adheres less well; if it is too hot, the adhesive can become soft and lose its adhesive strength.

- Cold environment (< 10 °C): Warm the adhesive tape to room temperature before use.

- Hot environment (> 30 °C): Use high temperature resistant adhesive tapes to prevent the adhesive from running.

- Outdoor applications: Select UV-resistant adhesive tapes to prevent degradation due to sunlight.

✔ Apply pressure – press firmly after application to maximise adhesion.

Many adhesive tapes require a certain curing time after application to develop their full adhesive strength. Immediately after application, the tape should be pressed down firmly and evenly to maximise the contact area between the adhesive and the surface.

Many adhesive tapes require a certain curing time after application to develop their full adhesive strength. Immediately after application, the tape should be pressed down firmly and evenly to maximise the contact area between the adhesive and the surface.

- Pressure-sensitive adhesive tapes (e.g. acrylic adhesive tapes): Roll or press on firmly to ensure a complete bond.

- Double-sided mounting tapes: Wait a few minutes before applying weight to the bonded object.

- Adhesive tapes for rough surfaces: Pressure allows the adhesive to penetrate recesses better.

4 – Removing adhesive tape without leaving residue – tips for different surfaces

Removing adhesive tape without leaving any residue can be a challenge, depending on the surface and adhesive. Whether it is successful depends on several factors, including the type of adhesive, the nature of the surface and the duration of the application. While some tapes are specifically designed to come off easily and without a trace, others leave stubborn adhesive residue due to ageing, heat or pressure. Particularly strong adhesives or porous surfaces such as wood and cardboard favour residues, as the adhesive penetrates deep into the structure. However, with the right methods and common household products, such traces can usually be removed gently. Here are the best tips for effectively removing adhesive tape and cleaning surfaces:

-

Remove slowly: Tape should always be peeled off slowly and at a shallow angle. A hairdryer can help with older or very sticky tapes by slightly heating the adhesive layer.

-

Removing residues: If adhesive residues remain, cooking oil or butter can help on smooth surfaces such as glass or metal – simply apply with a cloth, leave to act briefly and wipe off. Alternatively, vinegar or lemon juice works well on non-sensitive materials.

-

Solvent for stubborn adhesive residues: Cleaning alcohol, isopropanol or acetone can be used on robust surfaces such as plastic or painted wood. Take care with sensitive paints or plastics – test on an inconspicuous area first!

-

Porous and sensitive surfaces: Aggressive cleaners should not be used on materials such as untreated wood or fabric. Instead, an eraser or a microfibre cloth soaked in warm soapy water can help to gently remove the adhesive residue.

-

Post-cleaning: After removing adhesive residue, the surface should be cleaned with a mild detergent and clear water to remove any oil or solvent residue. A dry, lint-free cloth provides the finishing touch.

5 – Troubleshooting: Why isn’t my adhesive tape holding?

Surface too smooth or too rough? → Choose the right adhesive tape (strong adhesives or flexible versions)

Temperature too low? → Warm up the adhesive tape before bonding

Is there moisture? → Dry surface and pre-treat with primer if necessary

Is the adhesive tape of poor quality? → Order high-quality adhesive tape for better results

Alternative fixings: If adhesive tape does not hold, liquid adhesive, mounting tapes or suction cup solutions may be an alternative.

6 – Apply adhesive tape correctly: The most important things at a glance

The choice of the right adhesive tape depends largely on the surface. While smooth materials such as glass or metal favour chemical adhesion, rough surfaces such as wood or textiles require adhesive tapes with mechanical adhesion. Optimum results can be achieved with the right surface preparation and the right adhesive tape. The 5-point plan for the correct application of adhesive tape:

- Prepare the surface: It must be clean, dry and free of grease – it is best to clean it with alcohol or soapy water.

- Choose the right adhesive tape: Use the right material (e.g. acrylic or rubber adhesive) depending on the substrate and application.

- Apply the adhesive tape correctly: Apply evenly and without air bubbles, applying firm pressure to improve adhesion.

- Observe the application time: Some adhesive tapes require several hours to develop their full adhesive strength.

- Remove correctly: Peel off slowly and at a flat angle, using heat or solvents if necessary.

If you want to be on the safe side, you can buy strong adhesive tape that has been specially developed for your desired surface. Careful removal prevents residue and damage. When used correctly, adhesive tape can fix and repair (almost) anything …

Tip: For difficult surfaces, it is worth carrying out a test application to find the best solution! Please contact us, we will be happy to advise you on the right adhesive tape! You can find tips and instructions for sealing a shipping box with adhesive tape in our blog article: The right adhesive tape for packaging.