Palletising is a well-known word in the logistics vocabulary of warehouses. This method of organisation, shipping or storage consists of placing goods on a pallet in order to ensure optimum protection and then wrapping it with palletising film.To carry out effective palletising, several pallet-wrapping techniques are possible: which are the most profitable, the fastest and the most practical?This article was updated in November 2020.

Manual palletising

The manual palletising technique consists of placing the products or American boxes (cartons) on the pallet and then wrapping it by hand in order to ensure the stability and solidity of the entire wrapping and packaging process. Wrapping is carried out by an employee dedicated to order preparation, who turns the pallet with a manual plastic film . This technique

- It is very easy to use;

- It reduces physical effort and therefore fatigue:

- It improves the quality of the packed pallet;

- It reduces the waste of packaging film by delivering a clean pallet.

under what circumstances can a portable machine be used?

A banding robot is particularly interesting for packaging products and cartons ..

- When the volume of pallets to be wrapped is small;

- When the load is too heavy to be moved to the fixed wrapping station, and therefore to limit pallet handling;

- When the pallets are wrapped outside the warehouse;

- When pallet wrapping is required at several locations, and therefore requires more flexibility: the portable machine can then be used in addition to the fixed wrapping machines.

palletising with semi-automatic or automatic machines

Semi-automatic and automatic wrapping machines are fixed tools that cannot be moved to the pallets. They wrap the pallet on motorised turntables with automatic turns of stretch film.There is a wide range of stretch wrapping machines and banding machines available, with variable wrapping rates: from 25 to 180 pallets per hour.The choice of machine therefore depends on the size of the company and the number of pallets to be dispatched per day or month. What are the advantages of a semi-automatic or fully automatic machine?

- It improves the safety of your employees;

- It improves the health of your employees;

- It improves the efficiency of your employees (e.g. by freeing up their time for other tasks);

- A semi-automatic machine requires only one employee to operate it;

- An automatic machine is self-contained and requires very little human control.

these automatic or semi-automatic pallet wrapping machines reduce the consumption of stretch film: some companies have thus recorded huge reductions in the cost of stretch film consumption, while improving the stability, wedging and solidity of the packaged pallets.

Strapping: manual or automated?

Strapping is essential to keep your loads on your pallets. However, traditionally, strapping a pallet manually requires the use of non-automated tools, which are not very intuitive, and which require the use of a consumable: a steel clevis that must be crimped. What if you were to equip yourself witha pallet strapping machine? Two types of palletising machines exist

- Needle strapping machines: the operator passes the strap underneath the pallet, then retrieves it from the other side, and can then weld it.

- Mobile strapping machines: as the name suggests, they can be moved around the warehouse and are available in semi-automatic (the strap is always tensioned manually) or fully automatic (both the strap tensioning and the welding are done by the machine).

| RAJA tip: If you are a high-speed palletiser, you may want to consider our fully automated strapping solutions. Many warehouses choose to integrate their strapping machines with automatic production lines, based on rollers, conveyors and trolleys. In short, robotics can be used for your palletising. |

palletising and transport

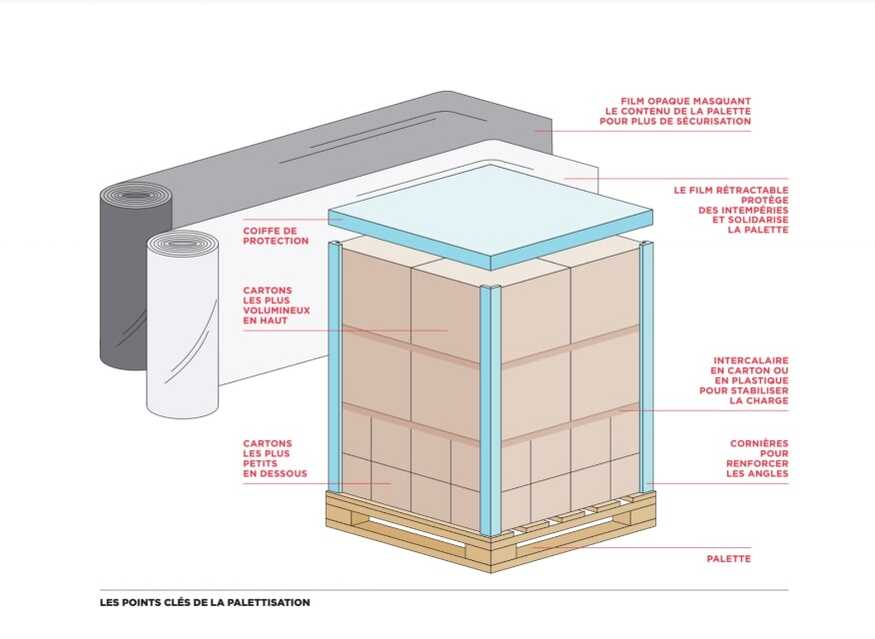

Fragile and unsecured palletised loads (e.g. poorly shrink-wrapped) can lead to certain logistical problems. Good palletising improves transport conditions, so ensuring that your parcels are safe and secure will guarantee impeccable delivery and improve customer satisfaction. Manually shrink-wrapping a pallet can cause quality problems: if the shrink-wrapping relaxes during transport, the load will be weakened or even detached, and the goods may arrive in a poor state.

It also takes much longer to shrink-wrap manually: an employee spends an average of 15 minutes per pallet.

Mechanising palletising

Mechanisation..

- improves the speed of your operations,

- reduces the effort of the pickers and reduces injuries(RSI)

- allows for consistent quality of your pallets,

- optimises the use of film quantity and allows you to make significant savings over the year.

automatic or semi-automatic palletisers become indispensable as soon as the company increases its daily palletising rate and the loads become increasingly heavy and difficult to handle and secure on the pallet

The three key points to remember

- Manual pallet wrapping is of course possible, but it must be borne in mind that it increases the drudgery of the work for the employee and also concerns industries and companies that send a very small volume of pallets per month and do not have the need to invest in fixed equipment.

- On the other hand, as soon as the rate of production or packaging increases, the company has a lot to gain by investing in an automatic or semi-automatic stretch wrapping machine: time saving, less human effort, increased efficiency, pallets better secured and ready for transport, reduction of stretch film waste, etc.

- Mechanisation makes it possible to speed up and improve pallet wrapping systems thanks to wrapping machines capable of wrapping up to 180 pallets per day, while offering loads that are better secured for transport and therefore less fragile.