If you’re just starting out in e-commerce, you’ll need to focus on your packaging. Packaging has a vital commercial function these days and plays an important role in customer satisfaction. But it’s difficult to do a good job without the right tools. Learn how to make your own packing table to optimise the work of your preparers.As the

last element in the transaction between you and your end customer, packaging must make a good impression.

It’syour company’s image that’s at stake! You’ll need to take the time to design solid, attractive packaging that conveys a serious image of your company and helps people appreciate your products.

But how do you go about it?

first and foremost, you will need to provide your order pickers with an adequate and ergonomic workstation. The aim is to maximise their productivity and minimise the risk of musculoskeletal disorders (MSDs) linked to poor posture. There are, of course, ready-made industrial workstations or professional workbenches that you can buy second-hand. But in the first case, you risk spending a lot of money and in the second case, you risk getting back a poor-quality workstation. So, avoid both risks: build your own order-picking table. This way, you will have total control over the costs and be able to build a customised, ergonomic workstation that meets your needs

Packaging, a real added value for customer satisfaction

Today, packaging and wrapping go far beyond their sole function of protecting goods. More innovative, even connected, they allow customers, but also logisticians, to benefit from precious information on the state of the delivery at a given moment. For the customer, packaging plays a major role in his satisfaction. It represents a case in which he will find the product he has ordered. This is the philosophy fully embraced by Bergamotte, a specialist in home delivery of flowers, which relies heavily on the quality of its packaging.

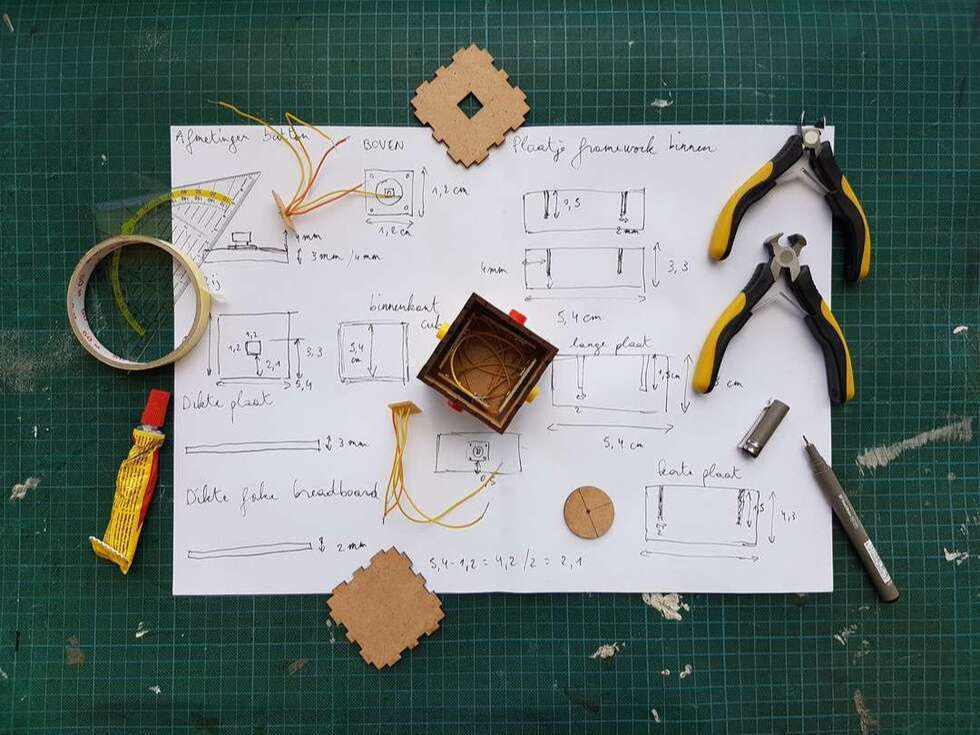

Essential tools and materials

before you get down to the nitty-gritty of the job, it’s important to review the tools you’ll need. To build your own customised picking bench, you’ll need:

- Metal shelf, size 192 x 120 x 50 cm;

- MDF panels of 1200 x 600 x 16 mm and 1200 x 600 x 3 mm;

- Two 2000 x 12 mmsteel tubes ;

you have everything? Great. Let’s get started.

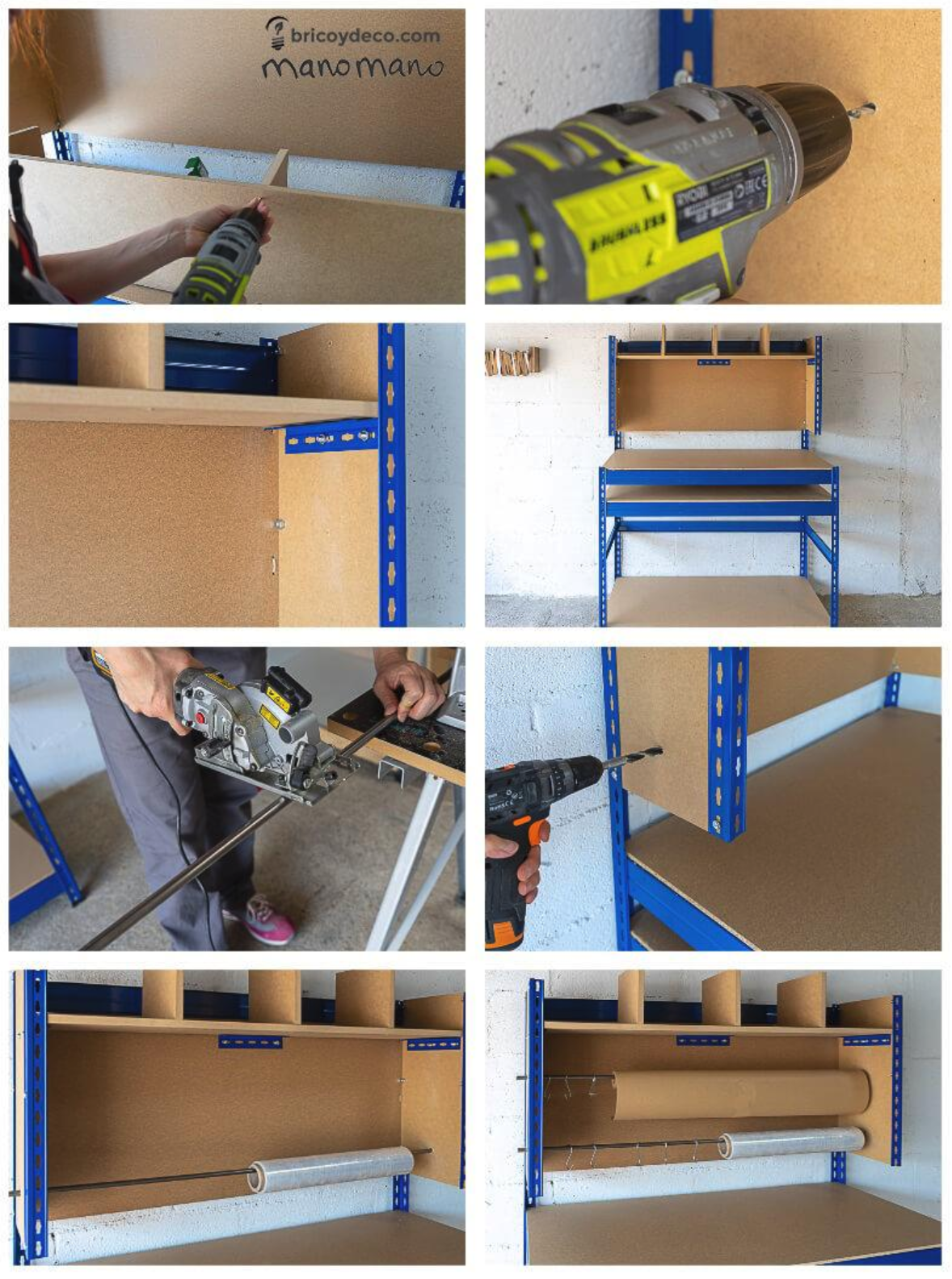

Steps to follow to make your industrial packaging table

Assemble the lower part of the metal shelf

the first step in building your mobile workshop workbench is to assemble the bottom part of the workbench. To do this, you will need

- 8 profiles of 96 cm ;

- 4 uprights of 120 cm and 4 of 50 cm for the shelves;

- 8 steel reinforcing bars;

- 4 chipboard boards of 1 cm thickness.

simply assemble the profiles and the three tiers to form a table.

Fitting the top of the shelf

now that your table has been assembled, you need to work on the upper part of the shelf. It will have three sides and a shelf with a divider. Let’s break down the steps

- Join two 96 cm profiles with one of the remaining 120 cm bars.

- Place the unused chipboard board on the lower part of the shelf made in the first step. To support the profile, drill holes in the board to match the holes in the profile and fix the two parts together using the clamps.

- Cut the two MDF boards to the following dimensions: 500 x 250 x 16 mm, drill them and then screw the bolts to the two profiles of the structure created earlier.

- Cut the two remaining profiles to a length of 50 cm.

- Attach the two 50 cm long profiles to the two 50 cm long boards, taking care to form the sides of the upper structure.

- Attach the lower and upper parts of the shelf to the 90 cm long profiles of the upper structure using bolts.

Laying out the shelf and its accessories on the top part

now let’s build the upper part of the workbench, which will hold the accessories needed to prepare orders

- Cut an MDF board to the following dimensions: 120 x 25 cm, and 3 dividers with dimensions of 20 x 25 cm. Attach the three dividers to the board every 30 cm to form 4 compartments of 30 cm each, which you attach with wood screws.

- To attach the shelf to the upper part, use the leftover profiles cut out in the previous step and cut them into 2 mini profiles of 20 cm each and 1 profile of 4 cm.

- Attach the profiles to the lower part of the panels of the upper part of the table, about 12 cm from the top edge. Then attach the 40 cm profile to the middle part, and one 20 cm profile to each side part with the bolts.

- Finally, place the board with the dividers.

tip: By making two holes in the side panels, you can attach the 130 cm steel bars that will support the protective packaging

Make the drawers for storing the accessories

last step: this consists of making the drawers with dividers to organise the accessories that are essential for a the workstation is complete

- Cut 2 MDF panels to 112 cm long, 7 cm high and 4 boards 45 cm long and 7 cm high.

- Form the boards into a rectangle and screw them together. Screw the two remaining 45 cm boards together to form dividers. Finally, nail the 3 mm thick MDF boards to the back to form the drawers.

- Drill holes in the front and place the two handles about 30 cm from the edge.

The advantages of creating your own packing station

as we have seen, buying a turnkey industrial packing table is expensive when you start your business

- a solid and contractual guarantee

- the assurance of a packing station proven by hundreds of companies, thus a minimum of ergonomics for your operators.

by opting for manufacturing, you can make your workshop table as you wish: add castors, adjust the size of the elements… you are in control, and at a lower cost. This way you can optimise your packaging table as you wish. If you have the time, this is an opportunity for you. Some reasons to opt for a professional workshop workbench; do-it-yourself or acquired directly from a partner such as RAJA

- It fully adapts to your needs;

- It improves the productivity of your operators, who have everything they need at hand;

- It reduces the risk of MSDs (musculoskeletal disorders), and therefore work accidents / injuries;

it encourages a better posture. For the picker, it means increased productivity. The quality of the package is better, and therefore customer satisfaction is maximised. Ata time when e-commerce is becoming the norm, and this norm imposes particularly intense workloads on logistics professionals, itis essential to be properly equipped. A packing station is a crucial element in a warehouse. It not only allows your workers to work in good conditions, but also improves their productivity. While many turnkey solutions exist, they are expensive, and do not necessarily fit your needs. Opt for the homemade one! This way, you can reduce your costs, and build the workstation that you really need three key points to remember

three key points to remember

- Today, packaging is commercially important and contributes to customer loyalty;

- When it comes to order picking tables, you can opt for an all-in-one industrial solution, or a home-made one, which is less expensive and perfectly adapted to your needs;

- A professional and ergonomic workshop workbench effectively reduces the risk of musculoskeletal disorders and accidents at work.