Storage methods, equipment to be considered, more or less thorough audits to be carried out, rules and standards in force to be complied with… So many elements to think about in order to organise your storage warehouse, and to optimise its flows and safety. Look no further: we have put together a complete guide to all the main principles that will help you to make your storage warehouse a space that is truly adapted to your activity.CONTENTS

vous pouvez dès à présent télécharger le guide “Les grands principes du stockage”, ou bien continuer la lecture de cet article.

1. Les règles de base en stockage

Pour bien organiser son entrepôt, il s’agit tout d’abord de trouver la méthode de stockage qui vous aidera à optimiser les flux de marchandises et d’opérateurs, pour le faire gagner en performance in fine.

Commençons donc par observer les différentes méthodes possibles, ainsi que les astuces pour choisir la méthode adaptée à votre type d’activité.

La méthode ABC

Connaissez-vous la loi de Pareto ? Si oui, vous connaissez déjà le grand principe de la méthode ABC, qui vous aide à stocker vos produits selon leur taux de rotation.

La loi de Pareto, appliquée à la logistique, explique que 20% des articles stockés correspondent à 80% de la valeur totale du stock.

C’est pourquoi la méthode ABC va consister à entreposer les produits dans l’entrepôten fonct

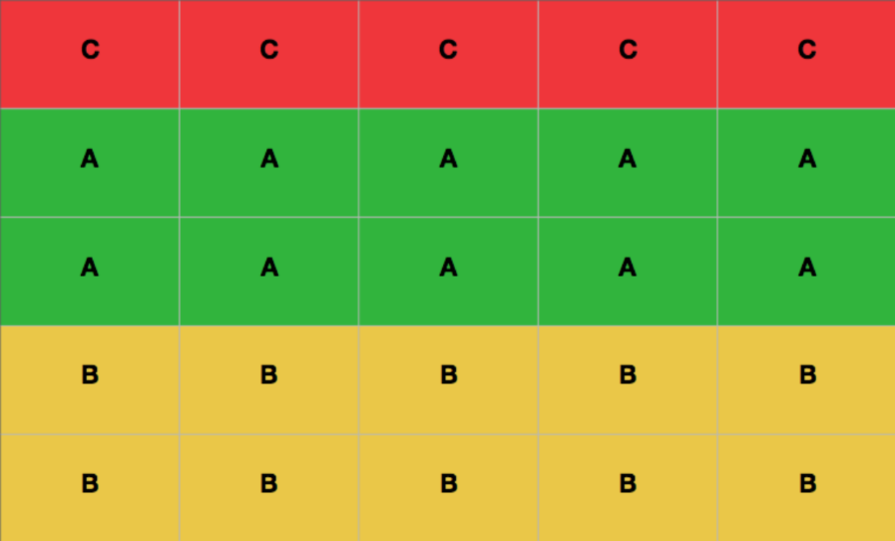

- Category A corresponds to the famous 20% of the references that undergo 80% of the rotations. These products must be at gripping height for the order pickers.

- Category B corresponds to 15% of rotations, and 30% of references. These products, less often taken out of stock, can be found at the bottom of the shelves.

- Category C corresponds to only 5% of rotations, and 50% of references. Products in this category, which are rarely taken out of stock, should be placed high up in the shelves.

Diagram of the arrangement of goods on a shelf or rack, according to the ABC method

Diagram of the arrangement of goods on a shelf or rack, according to the ABC method

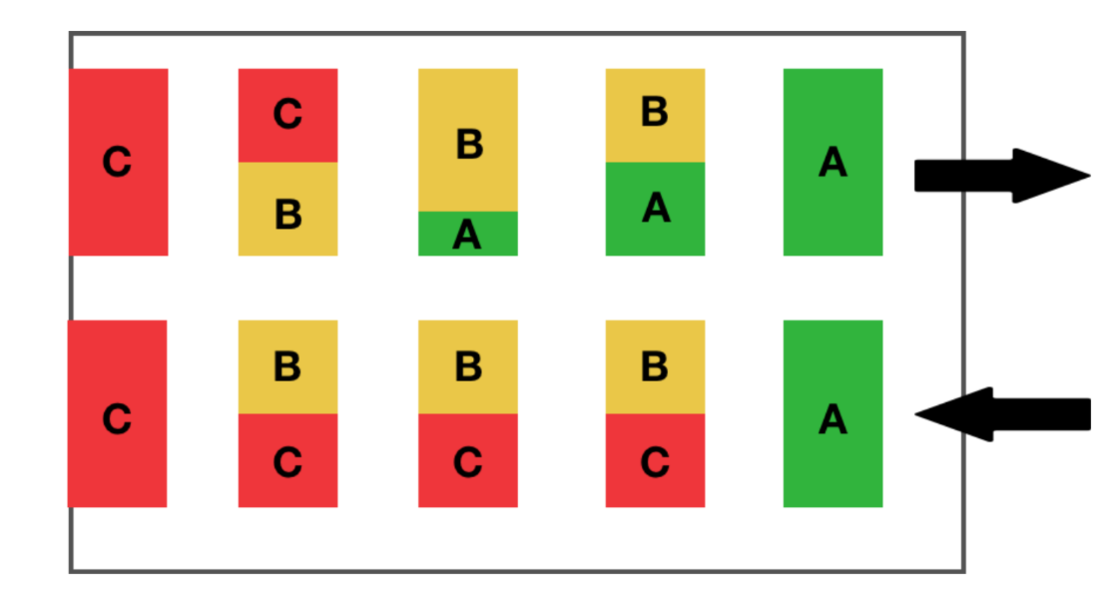

It is also possible to think of the organisation of the warehouse itself in terms of the ABC methodthe objective is to optimise the picking flows of the operators.

the A products, with a very high turnover, are found close to the order picking area, and the further down the warehouse you go, the more you find products with a low turnover: first the Bs, then the Cs

Diagram of a warehouse organised according to the ABC method

Diagram of a warehouse organised according to the ABC method

voilà une première méthode de stockage que de nombreux entrepôts choisissent pour optimiser leur stock.

L’optimisation des flux : les systèmes LIFO et FIFO

Les secondes méthodes de stockage qu’il faut connaître sont les méthodes dites LIFO et FIFO.

Il s’agit de deux méthodes antagonistes, chacune liées à des méthodes comptables particulières.

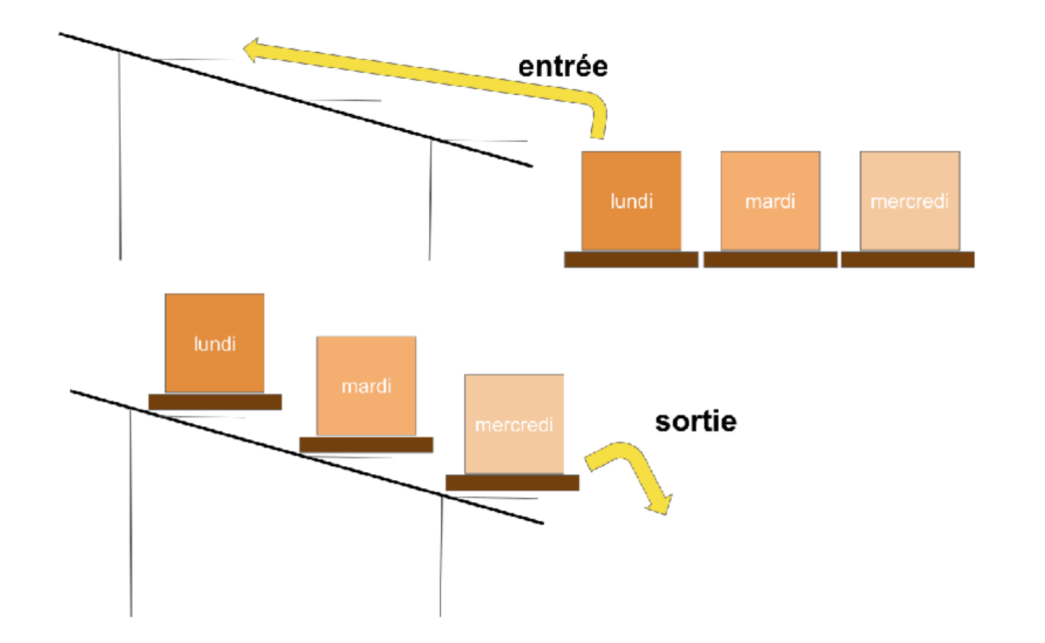

La méthode LIFO, soit Last In First Out (Dernier entré, premier sorti) met au plus près de l’espace de colisage les derniers produits entrés en stock. L’idée, comme son nom l’indique, est de sortir le plus rapidement ces produits, pour optimiser leurs flux dans l’entrepôt.

La méthode FIFO, soit First In First Out (Premier entré, premier sorti), elle, consiste à faire le contraire. Les produits entrés en stock il y a longtemps sont stockés au plus près de l’espace de colisage, pour être proches de la sortie, et voir leurs flux optimisés.

Vous connaissez désorm

- If you opt for manual handling, a few centimetres of clearance in height and width will suffice for your operators.

- If you choose to use a machine, make sure that there is at least 10 cm of clearance, both in height and width, between the different compartments.

quoiqu’il en soit, votre but est de trouver le parfait équilibre entre la réduction du stockage entre les cases, et la rapidité d’exécution des opérateurs pour picker vos produits.

Avec ces éléments en tête, vous êtes désormais prêt à choisir la méthode stockage qui convient réellement à votre activité et à votre entrepôt.

Comment choisir sa méthode de stockage ?

Il est temps de choisir, en fonction notamment de vos types d’articles et du taux de rotation de vos produits, la méthode de stockage adaptée.

Si vous vendez des produits périssables, avec une Date Limite de Consommation ou d’Utilisation, il vous est absolument nécessaire de choisir la méthode FIFO. Seule elle peut vous permettre de faire sortir les produits les plus anciens en premier.

Vous pouvez tout de même coupler cette méthode FIFO avec la méthode ABC pour optimiser le picking de vos opérateurs, et limiter leurs déplacements dans l’entrepôt.

Pour tou

- Make a note of the number of items, the size and weight of the products stored over the last 12 months, which will help you in the next part of this article to determine which type of shelf or rack best suits your products.

- Find the items that account for 80% of your sales and apply the ABC method discussed above.

- If you have different seasonal flows, consider reorganising your warehouse accordingly. Certain products, ordered in mass during certain seasons, will deserve to be moved from category B or C to category A, to optimise picking flows.

caution: If you store at height, do not forget to have an expert assess the strength of the floor or concrete slab, as regulations require that racks and shelving be anchored to the ground.Let’s now review the different types of storage you can choose from.

2. The different types of storage

You can now choose the appropriate equipment according to your preferred method, as well as the type of products you store. Here are 5 typical types of storage, to be chosen according to your needs.

High turnover storage on racks / shelves in aisles

This type of storage, as its name indicates, is intended for warehouses with high turnover products, and therefore particularly for those that apply the FIFO method. It includes

- High turnover products near the packing area, at gripping height;

- Slow-moving products at the back of the aisles.

products are stored according to their weight: the heavier they are, the lower they are on the shelves.Make sure you limit the height of your shelves to a maximum of 2000 m, for better ergonomics.What accessories will you need?

- From the point of view of shelving, opt for

- Sloping shelves or horizontal shelves for small and medium-sized warehouses;

- Mixed shelving for larger warehouses, which allows you to store both pallets at height and products in picking at man height.

- To optimise your picking, don’t forget to provide yourself with

mezzanine storage with posts

This type of storage is based on the same principle as the previous one, except that the warehouse is divided into two floors, independent of each other. On each floor, two clear zones allow you to create independent installations with shelving, storage areas and even office space. The idea is to free up as much floor space as possible from the posts, which take up a lot of space, in order to optimise the storage of the goods. You should not forget to take into account the mobile handling tools that could circulate on the floor, such as picking trolleys or pallet trucks.What accessories will you need?

- The material used to build the mezzanine must be chosen carefully to ensure optimum safety.

- To increase safety, also consider safety barriers around the posts and for access to the mezzanine.

- Marking tapes and other signs are compulsory, to be in the standards in terms of signage.

Storage on pallets with collars

This storage method is mainly suitable for products

- Non-palletisable, such as pipes, big bars, carpets;

- Highly seasonal.

it is a more flexible storage system than mass storage.What accessories will youneed?

this is the most common method of storage for

pallets

in a warehouse, especially for B2B warehouses. Before storing these pallets, be sure to define their characteristics. Note their dimensions, their loads, the direction in which they are picked up and the height of the first level, so that you can choose your shelving.What accessories will you need?

- You’ll need pallet racks that match the characteristics you’ve noted: choose the right ones from the wide range available.

- You will also need to put barrier protection on your racks.

- Don’t forget to have signage and mirrors in the warehouse, which will improve the visibility of your operators in the warehouse, and make it safer to move around.

high bay storage (narrow aisles)

When the shelving exceeds 7 metres, high bay storage is required. This method is particularly suitable for warehouses with a high logistical capacity. In this case, guide rails are used for the forklift operator in narrow aisles, which means that a beam is required at the bottom level. This is compulsory, as storage on the ground is impossible. This storage method requires the use of three-way machines, to avoid turning the forklift truck and to really optimise the width of the aisles.What accessories will you need?

- Floor guide rails;

- Satellite ladders on the edges;

- Ladder guards for the edges, and upright guards for the aisles;

- Pallet stops;

- Protective nets;

- Sprinkler support;

- Signage and load plates.

you are now ready to implement an optimal storage method to gain space, performance and safety in your warehouse.And to keep all these good tips in mind, don’t hesitate to download the summary guide of the main principles of storage