While automation and AI are poised to transform the way humans work in many organisations and sectors, McKinsey attests in a recent study that the transportation and warehousing industry has the third highest potential for automation of any sector, having identified more than 50 technologies that can be used to automate part of the supply chain.

Automation is already here

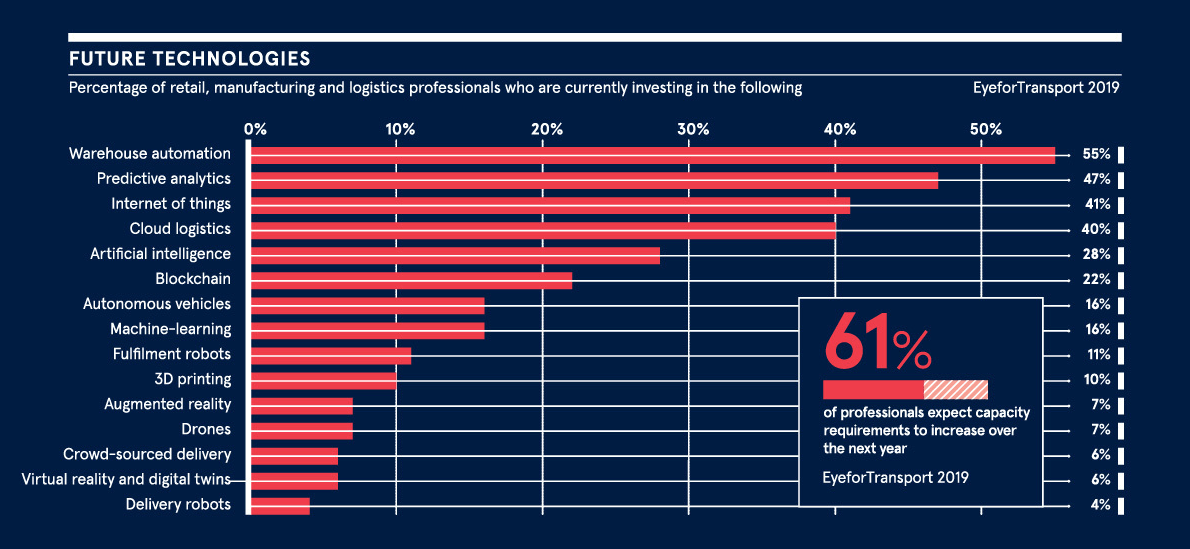

According to Visual Capitalist, 55% of retail, management and logistics professionals are already investing in warehouse automation and 47% in predictive analytics.

This trend is partly due to a growing labour shortage. Over the past decade, unemployment rates in the EU have almost halved, while the number of jobs needed in distribution centres continues to rise, especially during the holiday season when labour is at its most scarce. The situation is similar in the United States, where unemployment levels are at their lowest in half a century. So there is an underlying trend that is visible across the developed world.

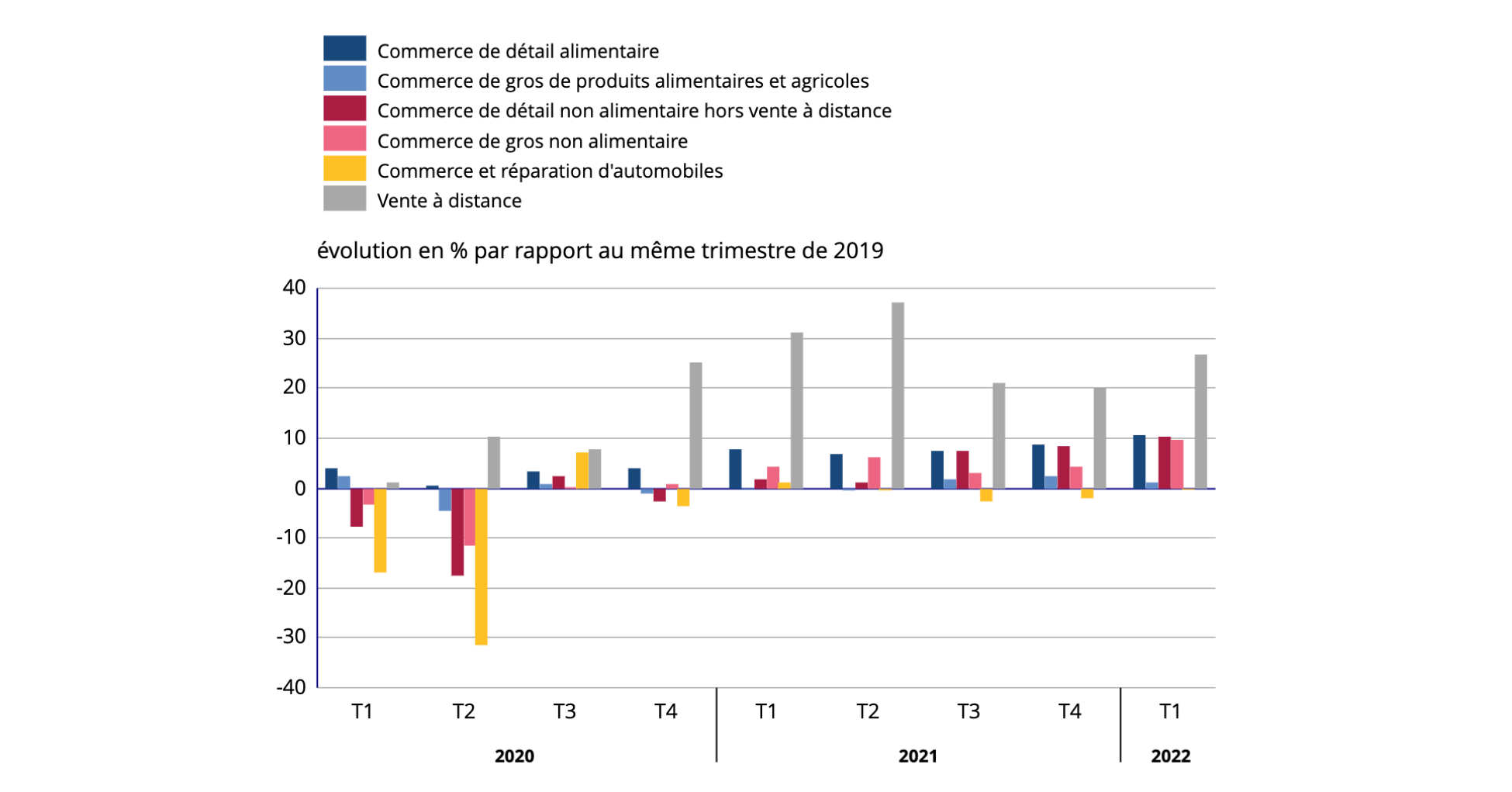

The trend towards automation has also been impacted by the growing demand from online retailers. A recent survey found that organisations estimated that e-commerce in 2020 would account for half of all sales, up from around a third the previous year.

This increase in e-commerce, accelerated by the Covid-19 pandemic, is driving increased investment in automation technologies within supply chain processes to quickly meet multi-channel and omnichannel requirements as well as same-day and next-day delivery.

Finally, the focus on transport and logistics automation has been made possible by promising advances in technology. For example, new pallet handling systems have reduced shipment processing time by 50%.

Advances in automation

Automation, along with machine learning and artificial intelligence, are key elements of the Supply Chain 4.0 concept (i.e. the next generation digital supply chain). The trend is enabled by advances in hardware and software to facilitate the handling and movement of goods, including highly efficient advanced robots in warehouses, smart sensor/Internet of Things applications and highly intelligent predictive analytics.

It is estimated that most supply chain operations could be automated by 2030, with AI-powered innovations taking over simple, repetitive tasks previously performed by people.

Many companies have already automated their frontline transactional purchasing activities. Automation has affected a number of blue-collar supply chain jobs in warehouses and distribution centres, and driverless trucks are poised to transform the logistics field, eliminating the need for millions of truck drivers (we know it’s a long way off, but it’s best to be prepared)

RAJA pioneers automation in its sector

RAJA, Europe’s leading distributor of packaging, office supplies and industrial equipment, has become one of the pioneers in its sector by equipping its historic distribution centre in Paris Nord 2 with an automated pallet storage system.

The first advantage of this automation is the storage capacity, which has now increased from 14,7000 pallets to 8,000 before automation. The second benefit is for the warehouse operators. Their work has been made much easier thanks to the lifts and shuttles controlled by software connected to a WMS that deposit and pick pallets at the right place. In addition, it will allow all the operators working on this new racking to acquire new skills in mechanics as well as in electronics.

In detail, it is the Atlas 2D ® solution from the supplier Stow that was chosen by the RAJA Supply Chain Management. These 12m high racks are composed of 3 lifts and 12 shuttles which lead the pallets in a storage of 6 floors and 30 aisles. All of this works thanks to the standardisation of the pallets (1200 x 800 mm or 1200 x 1000 mm) with a maximum height of 1.80 m.

As large as 6 football pitches, the Paris Nord 2 distribution centre was suffering from a lack of space with an occupancy rate that regularly reached 90% of its capacity. It was therefore essential to find a solution to meet the growing needs of RAJA logistics. That’s when logistics robotization appeared to be the solution for Laurence PAPEIL, Supply Chain Director of RAJA France.

The RAJA Group operates 15 distribution centres in Europe, 5 of which are in France, with a total surface area of 400,000m². The company guarantees delivery anywhere in Europe within 24/48 hours, depending on the time of order taking and the delivery location.

Automation: The economic benefits

The rate at which organisations adopt new platforms and technologies is largely dictated by the anticipated implementation and operating costs and the rate at which cost savings and increases in productivity, efficiency and service levels eventually offset these.

As automation is introduced at each stage of the supply chain: from order picking, through to delivery, the ability of logistics companies to adapt to peak demand, to handle shipments of all types and to select and pack individual, often customised, products increases.

The technology also enables smoother asset sharing in B2B environments, freeing up spare capacity in capital-intensive assets such as trucks, warehouses and even trains and ships.

In addition, major shippers and carriers are using data and analytics to forecast demand and optimise their routes more effectively than we could have imagined a few years ago. New routes powered by connectivity and analytics can produce efficiency gains of up to 25%.

Some shippers/carriers have reduced inventory by up to 75%, cut warehousing costs by 15-30% and reduced administrative costs by 80%.

Digital networks and Big Data: a source for automation

The integration of new SaaS and innovative platforms creates the digital network needed to facilitate the automation of supply chain execution. This enables the convergence of traditionally siloed supply chain functions, allowing end-to-end business processes to scale, synchronise and be optimised like never before.

A multitude of documents accompanies each stage of the supply chain. Data capture software digitises and captures data more quickly and accurately.

Cloud-based data management software increases the efficiency of logistics companies and speeds up invoicing and invoice management, as well as logistics management along the supply chain.

An automated CMR directly available to all players? We are not far from that.

Automation: Logistics trend indicators

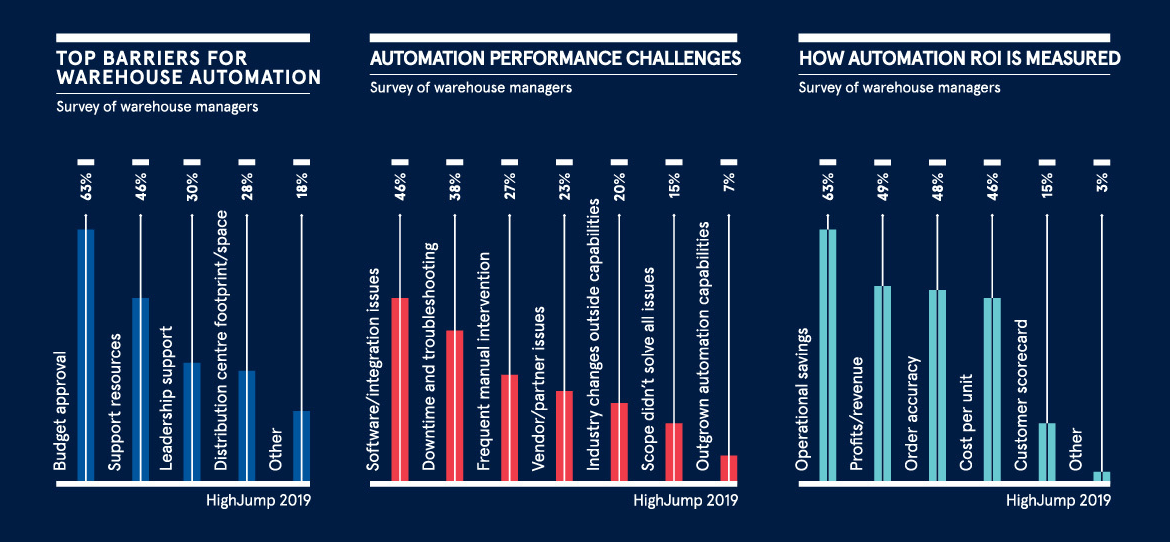

If 100% of logistics companies are not automated, it is because there are obstacles to their adoption and according to a study by Körder (formerly HighJump)in 2019, here are the main causes identified among these companies:

- Budget

- Unavailable external resources (support, project)

- Support from sponsors (management)

- Space or configuration of existing warehouses

Nevertheless, these investments tend to address existing issues, but new challenges arise in implementing these solutions, which you will find below:

- System integration issues

- Mechanical problems leading to downtime and troubleshooting

- Frequent and costly interventions

- Problems related to supplier development risk

- Poorly designed functional scope

Above all, in order to validate the investment to be made, it is necessary to be able to calculate the return on investment (ROI) which, according to the study carried out among warehouse managers, is calculated as follows

- Savings on operational costs

- Turnover and profit achieved

- Operational quality (number of order errors etc.)

- Cost per logistics unit

- Customer satisfaction

What are the advantages and disadvantages of automated systems?

Advantages

The main advantages of logistics automation are

- Real-time access to load data and data analysis. When you have access to load data and the ability to generate reports, you are able to make better business decisions.

- Reduce costly errors. In manual data entry, there can be a number of errors that lead to increased shipping and management costs (inventory, control…)

- Organisational control. Systems are usually flexible enough to adapt to the company’s business rules and, at the same time, powerful enough to force all users, internal and external, to follow policies that ensure efficient and cost-effective transport. For example, a company can set rules for selecting the most economical or fastest carriers, depending on the customer’s needs.

- Improved customer service through real-time cargo tracking, automatic pick-up, proper insurance and cargo accounting by integrating this information into order specifications.

- Scalability and speed. Automated warehouse systems offer easy access and more agile management of a warehouse (goodbye AS/400 screens), and all freight invoices can be consolidated into one weekly invoice, regardless of the number of shipments in each location.

A growing business can manage more orders and shipments without hiring additional staff or significantly increasing costs.

Disadvantages

Logistics automation also has some disadvantages:

- Less flexibility, both in processes and in process changes. In other words, it is doubtful whether it is possible to standardise certain processes so that they can be carried out more efficiently in an automated system.

A company that often has to adjust its processes to specific customer requirements may find it difficult to implement rigid automation.

- Consider the large number of actors in a supply chain: suppliers, manufacturers, customers, distributors, etc. All may present obstacles and be reluctant to include the necessary and mandatory technological solutions for automation.

Example: A supplier may not want to invest in the technology needed to share real-time information with its chain partners or adapt its packaging (pallet) to the requirements of the system.

It is therefore necessary to be able to know the entire supply chain and its stakeholders before implementing an automated system (storage, order picking or transport) or software that involves pre-requisites for its operation.

However, some systems are better adapted to the type of activity, such as the use of a conveyor or sorter. A stacker crane can be adapted to any type of container, whereas an autostore is designed for small products.

How can you find the right logistics provider?

On the Monprestatairelogistique.com platform, any company will be able to find and select the logistics service providers best suited to their needs. You will be able to sort according to the technical solutions offered by the logistics provider and thus target only automated and/or mechanised sites.

Each company will be able to search for a logistics provider whose expertise is relevant to its activities. There are more than 60 search filters to find the one that suits you through functional, technological, geographical or other filters.

Digitalisation is an important part of automation, and the MyLogisticsProvider.com platform allows you to respond to the first step: The search

Functionalities such as the automated Benchmark or the creation of standardised specifications will enable companies and logistics service providers to optimise their search or their customer acquisition.