Tertiary packaging plays a key role in any logistics strategy, as it has a direct impact on delivery quality and customer satisfaction. Properly optimised, it protects your products while reducing your costs and your environmental footprint.

Want to improve yours? Discover the seven keys to optimising your tertiary packaging to create the best possible customer experience for your brand.

What is tertiary packaging?

Tertiary packaging is a type of packaging used primarily for transporting and handling large quantities of goods. It groups sales units together to make them easier to handle, store and protect during logistics stages such as transport or warehousing.

Unlikeprimary packaging (in direct contact with the product) and secondary packaging (grouping together several units for sale), tertiary packaging is generally not visible to the end consumer – except in e-commerce, where the package is delivered directly to the end customer.

Examples of tertiary packaging include :

- Pallets

- Containers

- Wooden crates

- Large cardboard boxes

- But also all e-commerce packaging: crates, cases, envelopes, boxes, etc.

What is the role of tertiary packaging?

Tertiary packaging plays a crucial role in the supply chain by facilitating the transport, handling, storage and protection of goods.

Its main functions are as follows:

- Product protection. Tertiary packaging protects products against physical damage (shock, vibration), humidity, dust and other environmental factors. It prevents the risk of breakage or deterioration of goods, ensuring that they arrive intact at their destination.

- Ease of handling. It makes it easier and quicker to handle products throughout the supply chain. For example, the use of pallets or containers means that several units can be grouped together and moved more easily using forklift trucks or pallet trucks.

- Optimising storage space. Good tertiary packaging allows goods to be grouped compactly, maximising space in warehouses and transport vehicles. This improves space management and reduces the costs associated with storage and transport.

- Improved logistics efficiency. By standardising formats and loading units, tertiary packaging facilitates logistics planning. It enables transport and storage capacity requirements to be calculated more accurately, optimising logistics flows.

- Good identification and traceability of goods. Tertiary packaging often includes labels or barcodes to identify the contents, facilitate tracking and guarantee better product traceability. This ensures more accurate stock management and reduces the risk of errors.

What role does tertiary packaging play in the customer experience?

The benefits of tertiary packaging go beyond those seen internally by companies. In fact, this type of packaging has a more or less indirect impact on the customer experience.

Although not visible to the end customer, tertiary packaging can affect the quality of the product delivered. In particular, it reduces damage to goods by minimising the risk of breakage – which has an impact on customer satisfaction. It also helps to optimise delivery times because, when properly designed, it speeds up logistics operations.

And it ‘s in e-commerce that we’re seeing the real direct impact of tertiary packaging on the customer experience. When shipping e-commerce products, tertiary packaging ‘merges’ with secondary packaging.

In this sense, managing your tertiary e-commerce packaging means :

- Offering your customers an optimised unpacking experience. If tertiary packaging is also designed for unpacking comfort (also known asunboxing“), it can add a touch of attention that customers appreciate.

- Reduce the number of product returns. Fewer damaged products means fewer returns, which will boost your customers’ confidence.

7 tips to optimise your tertiary packaging for a better customer experience

Want to improve your current tertiary packaging? Follow our seven best practices to boost your customer experience.

Put product protection first

Use strong tertiary packaging that is well adapted to the size and weight of your products. This reduces the risk of breakage or damage during transport, reducing returns and increasing customer satisfaction.

Examples to emulate

|

The right type of packaging for your transport method. For example, on your pallets, choose stackable boxes, which can be stacked on top of each other without the risk of crushing the cartons. |

|

The right cardboard packaging flute. Choose single, double or triple flute depending on the weight and protection needs of your goods. |

|

The right cushioning material. Kraft paper to absorb shocks, tissue paper to protect goods that are sensitive to scratches, paper padding to limit the movement of products in tertiary packaging… There’s no shortage of choice, and you need to choose the right one to protect your products properly. |

|

Packaging with integrated cushioning. Think about this type of e-commerce packaging, such as packaging with a plastic film to immobilise the product in the packaging method, or a box with integrated foam padding. |

To find the most suitable cardboard packaging for your products, use the RAJA crates, cartons and boxes search engine. More than 1,200 formats are in stock at any one time, suitable for all products!

Optimise packaging to reduce your transport costs

By choosing lightweight, low-volume packaging that guarantees product safety, you can reduce your transport costs. As a result, you can offer quicker and cheaper delivery options, which is perceived positively by your customers.

Examples to emulate

|

Padded envelopes and pouches for extra protection and lightness. |

|

Embossed paper bags for your smallest shipments. |

|

Air cushioningas an alternative to paper or packing particles, for lightweight protection. |

Opt for sustainable and eco-responsible materials

The ecological footprint of their purchases is increasingly important to your customers. Choose eco-responsible materials to reinforce your brand image and reassure your customers of your environmental values.

Examples to emulate

|

Recyclable tertiary packaging, which can be recycled when placed in the right sorting stream. |

|

Biosourced packaging, made from raw materials of biological origin (plants, agricultural waste, etc.) rather than fossil resources, or from sustainable management of the materials used. |

|

Packaging made from recycled materials, such as bioplastic packaging or recycled cardboard containers. |

|

Ecological alternatives to petro-sourced packaging, such as adhesive tape made from kraft paper or paper strapping. |

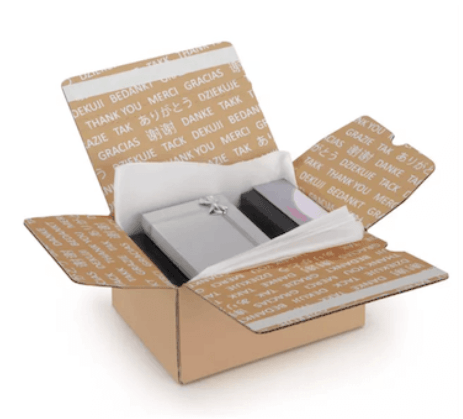

Customise your packaging solutions

Add branding elements to your tertiary packaging, such as brand labels or personalised stickers, or choose to personalise your packaging completely. This way, you leave a positive impression, even if the customer only sees it briefly, and it contributes to the overall image of the brand and its uniqueness.

Examples to emulate

|

Customised cushioning materials, such as tissue paper printed with your brand colours or logo. |

|

Customised containers, where you print or emboss elements specific to your brand. |

|

Connected tertiary packaging, where you print a QR code that customers can scan to continue their discovery of your brand. The code takes the consumer to a web page where they can watch a video on how to use their product, take part in a competition or find out more about your company’s values. |

Make packaging easy to open and manage

Choose packaging that is easy for your partners and end customers to open and handle. By doing so, you can enhance your customer experience, both in e-commerce and traditional logistics.

Examples to emulate

|

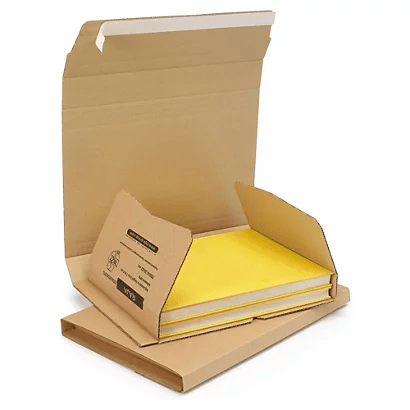

Adhesive-sealed packaging, easy to prepare and open. |

|

Ergonomic opening packaging, which makes it easier to unpack your products. |

|

Return packaging, which withstands e-commerce shipment and return, and has two adhesive strips for this purpose. |

Automate your tertiary packaging

If possible, invest in automating your tertiary packaging process to ensure uniform protection and reduce errors. By standardising and automating your tertiary packaging, you can ensure consistent quality for your parcels and save time during order picking. This reduces errors, minimises damage during transport, and ensures consistent deliveries, contributing to a better customer experience.

Examples to emulate

|

Automatic or semi-automatic strapping machines, for pallets or parcels, to secure all your parcels in the same way. |

|

Wrapping machines, to fully or partially automate the pallet wrapping process. |

Communicate your packaging choices

One last crucial tip: add messages on the packaging or in the communication tracking your parcels to explain your tertiary packaging choices. For example, you can indicate whether your packaging is eco-responsible to highlight your commitment to the environment and reassure customers.

Armed with these few best practices, you’re ready to enhance your customer experience with tertiary packaging that’s both protective and attractive.