Palletising goods is a real challenge for many logistics operators. This task, as crucial as it is in the warehouse, requires a great deal of effort on the part of operators – both physical effort, to handle heavy loads, and logical effort, to organise the parcels correctly on the pallet.

To meet this challenge, you need a key element: a palletising plan.

Find out everything you need to know about it here: how to design it, and the key equipment you need to ensure a safe and reliable palletising process.

What is a palletising plan?

A palletising plan is a diagram used to plan how your parcels should be arranged on a pallet.

A palletising plan allows you to :

- Optimise the pallet’s loading capacity, so that as many packages as possible can be stacked on it while protecting the goods

- Make pallet handling simple and safe for logistics operators, thanks to optimal package stability

That’s right: properly packing your goods on a pallet requires a real packaging method!

How do you create your palletising plan?

Stacking your parcels on a pallet can’t be left to chance. To be successful, you need an optimum palletising plan.

To create this plan, follow these five steps:

- Measure and weigh each parcel to be palletised accurately. This is the essential starting point for knowing how you’re going to stack the different parcels, and for complying with the maximum pallet load.

- Identify the pallet to be used. Find out the size of the pallet and the maximum load it can carry.

- Identify the handling method to be used. Depending on whether your pallet will be handled using pallet trucks, forklift trucks or automated systems, you will need to leave enough space for the equipment to access it easily. For example, the blades of a pallet truck must be able to fit under a pallet without affecting its stability.

- Take intoaccount the constraints associated with transporting goods. For example, is there a maximum volume and height to be respected depending on the mode of transport (transport on conveyors, road transport by lorry, rail transport, etc.)? How much overhang (i.e. how much packaging can protrude from the pallet) is authorised?

- Calculate the palletising plan itself. Now it’s time to create a loading matrix so you know where to stack which package on the pallet. Make sure you plan for the heaviest packages to be stacked at the bottom of the stack, and give preference to crossing packages from one layer to the next, to ensure the stability of the palletised load. Make sure that the loads are well balanced on the pallet, with limited empty spaces, to limit crushing of the goods.

There are several methods for defining your loading matrix.

Some logisticians calculate this matrix by hand, using an arithmetic method, taking into account the lengths and widths of the packages, to determine the number of packages to be placed on each side of the pallet.

Others choose to create “master plans”, where they know they can stack X number of boxes in X number of rows. This method allows them to calculate the theoretical number of parcels per layer, then divide the surface area of the pallet by that of the parcel, and then choose the one that best fits the pallet from the different layouts.

Finally, if you palletise at high speed in your warehouse, it may be worthwhile to equip yourself withpalletising software. This automates the calculation of your palletising plan. You enter the dimensions of the parcels, the size of the pallet, the maximum weight to be respected, and all the other necessary criteria, and the tool takes care of the rest.

The crucial equipment for preparing your pallets

Whether you’re palletising manually or packing your pallets with the help of special machines, you’ll find everything you need here to palletise your goods properly on your packaging line.

Choosing the right type of logistics pallet

To pack your goods properly, you first need to make sure you select the right type of pallet for your needs.

These pallets should be chosen according to :

- Their size. The standard size of a universal logistics pallet, known as an “ISO pallet”, is 120 x 100 x 13.1 cm. However, half-pallets and quarter-pallets are also available if you need to palletise a smaller volume of products.

- Material. There are, of course, traditional wooden pallets. But there are also alternatives, such as plastic or recycled moulded wood pallets.

- Stacking. If you want to optimise your storage space by stacking your pallets empty, or stacking several full pallets, choose stackable pallets.

Note: if you’re exporting, you’ll need to choose pallets that meet ISPM15 standards, which ensure that the wood of the pallet is not infested with pests. You should therefore choose wooden pallets treated to the standard, or plastic pallets.

Need to find out more? Find out here what type of pallet to choose for shipping your goods.

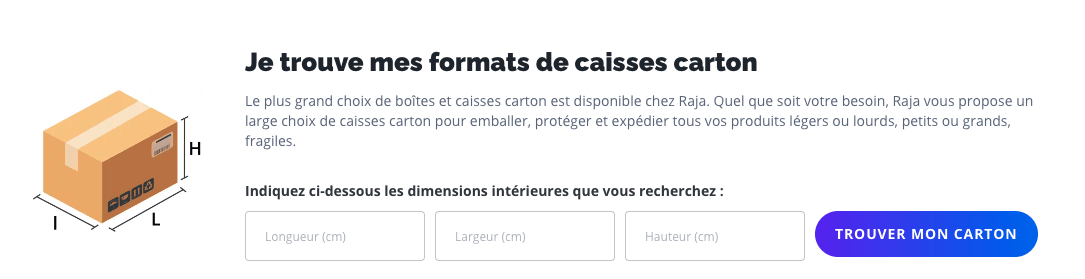

Selecting your palletisable cardboard boxes

The second material to choose for optimum palletisation is your cardboard boxes. These must be designed for palletising – they are then called “palletisable crates“.

They should be chosen according to :

- The weight of the products to be palletised: choose the right flute, between single, double or triple flute. Consult our article on cardboard flutes to select the one best suited to your needs.

- The final size of the pallet. The aim here is to limit the amount of empty space on the pallet.

To find the ideal carton for your pallets, use the RAJA carton search engine. Over 1,200 formats are available from stock!

Opt for the right palletising film

Wrapping your pallet is a crucial step in protecting your palletised loads throughout storage and transportation. This brings us to a new necessity: choosing your palletising film with care.

You have several options when it comes to palletising stretch film:

|

Cast stretch film is suitable for pallets of all sizes, and is available in transparent or opaque versions, depending on whether or not you want to guarantee the confidentiality of your palletised goods. |

|

Blown pre-stretched film makes manual palletising easier, and is suitable for medium-weight pallets with slight corners. |

|

Manual stretch film for palletising is a real innovation. It is 100% recyclable, can be stretched by up to 30%, and can be applied to light, homogeneous pallets, making your palletising process eco-responsible. |

Do you palletise at high speed in your warehouse? Consider investing in a stretch wrapping machineThis is a machine that partially or fully automates pallet wrapping. This will speed up your wrapping rates and minimise the risk of Musculoskeletal Disorders associated with this packaging phase.

To find out more, discover the 7 mistakes to avoid when filming a pallet manually.

Think about these additional protective elements

As well as shrink-wrapping your pallets, take the time to consider purchasing these materials, to ensure optimum protection for your loads:

|

Pallet boxesThe pallet box, which allows you to respect the maximum dimensions of the pallet and makes it easier to fill. |

|

Interlayersto be placed between the layers to give the pallet maximum stability. |

|

Cardboard corner protectorsThese protect the corners of the pallet from impact, and reduce the risk of damage to goods during strapping. |

|

The pallet cover, which protects the top of the pallet from dust or moisture, for well-protected storage. Available in paper, recycled plastic and cardboard. |

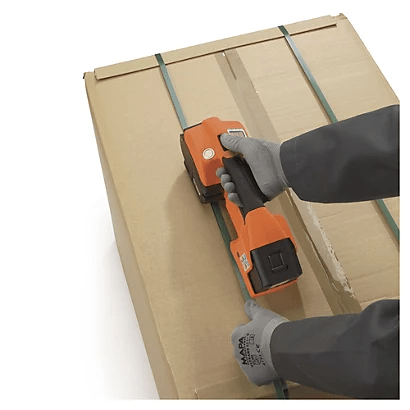

Securely strap your pallets for better protection

Finally, a well-secured pallet is a strapped pallet. Depending on your palletising rate, your logistics operators will need different equipment to strap your pallets.

|

A manual tensioner may be sufficient if you strap very few pallets each day. |

|

The mobile manual strapping machine is ideal for strapping anywhere in the warehouse, safely and with minimum effort. |

|

The semi-automatic strapping machine reduces the risk of RSI associated with logistical strapping, and increases order-picking speed. |

Armed with a good palletising plan and the right equipment, you’re ready to ensure safe order preparation, both for your products and your logistics operators.